Crankshaft polishing machine

A polishing machine and crankshaft technology, applied in grinding/polishing equipment, grinding frame, grinding machine parts, etc., can solve the problem of waste chips splashing to the center drilling, affecting the grinding effect, etc., to reduce clamping times, improve grinding efficiency, save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is further described in detail through specific implementation methods:

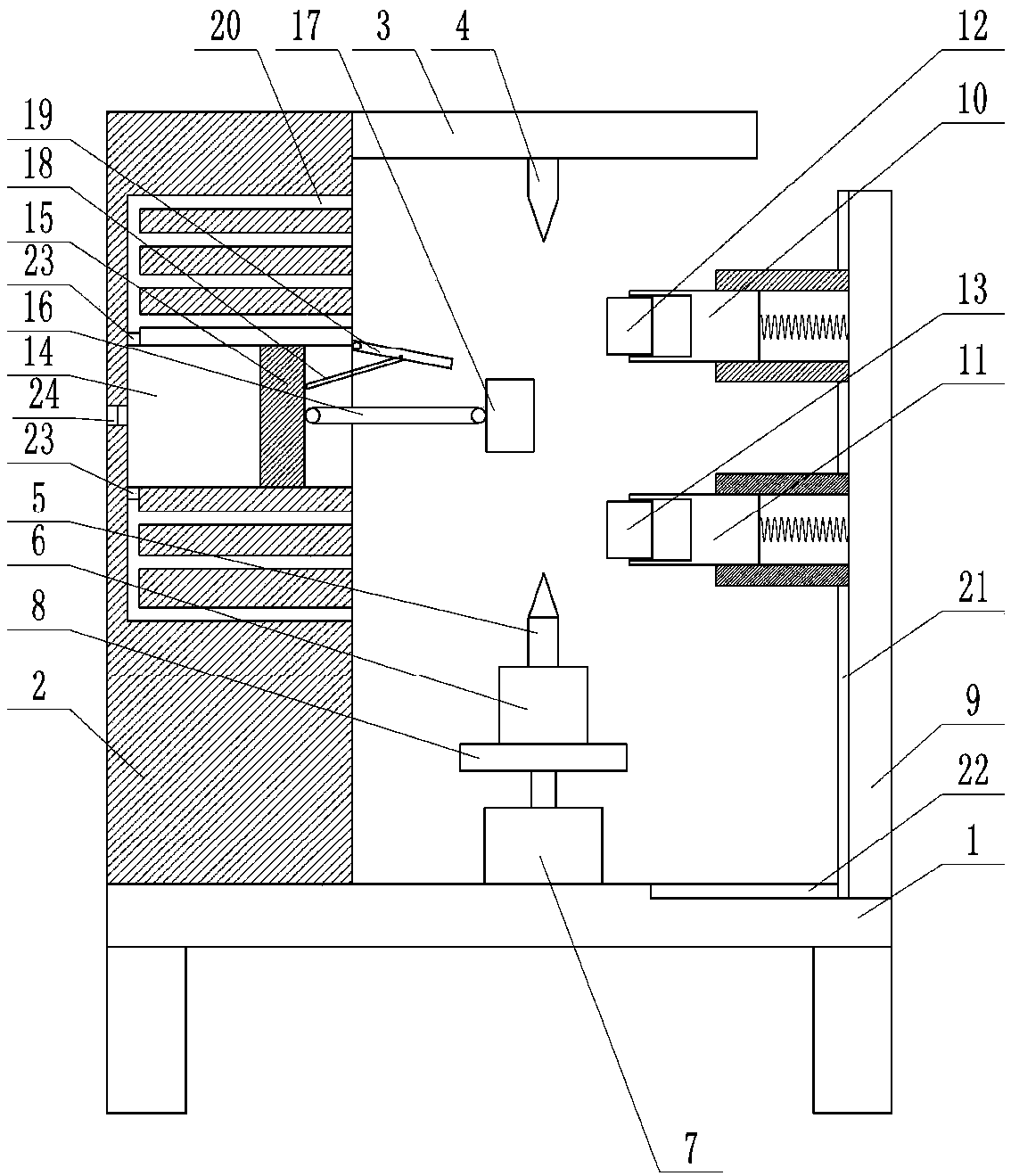

[0018] The reference signs in the drawings of the description include: workbench 1, column 2, beam 3, first thimble 4, second thimble 5, motor 6, cylinder 7, support platform 8, support rod 9, first support rod 10, The second pole 11, the first grinding wheel 12, the second grinding wheel 13, the sliding hole 14, the slider 15, the connecting rod 16, the splint 17, the ejector rod 18, the push plate 19, the blowing hole 20, the vertical groove 21, the sliding Groove 22, first one-way valve 23, second one-way valve 24.

[0019] Such as figure 1 As shown, a crankshaft polishing machine includes a workbench 1, a column 2 is installed on the left side of the workbench 1, a horizontal beam 3 is installed on the upper part of the column 2, a first thimble 4 is installed on the upper middle of the beam 3 through a bearing, and the workbench 1 There is a cylinder 7 with the piston rod arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com