Photosensitive film and preparation method thereof

A photosensitive film and photosensitive layer technology, which is applied in the field of engineering plastics, can solve problems such as cracking and film deformation, and achieve the effects of strong adhesion, low cost, and avoiding paint pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

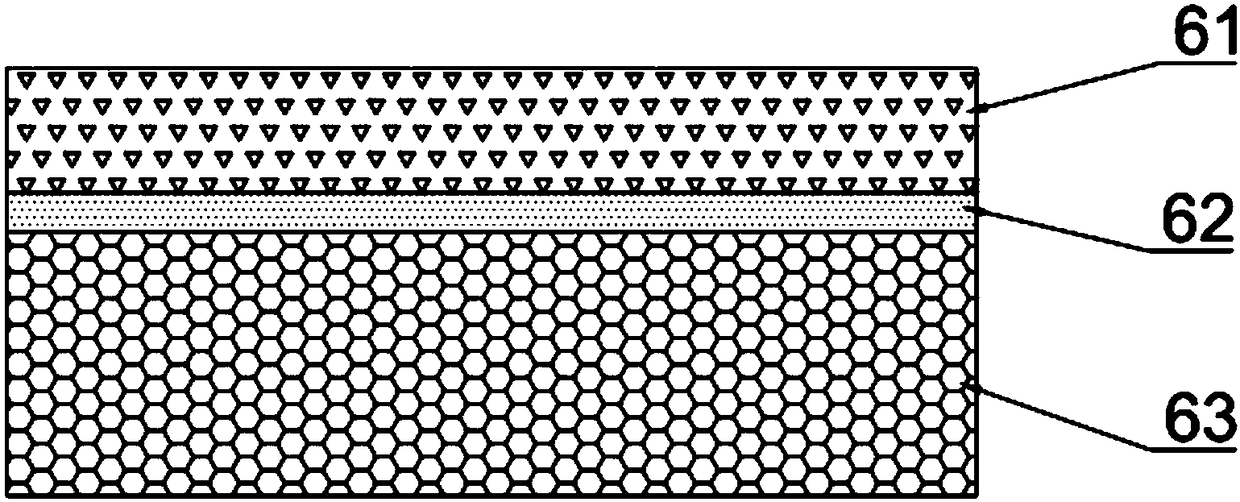

[0029] Such as figure 1 Shown, a kind of photosensitive film comprises polycarbonate PC layer 63, polymethyl methacrylate PMMA layer 61 and the photosensitive layer 62 between polycarbonate PC layer 63 and polymethyl methacrylate PMMA layer 61 The raw materials of the photosensitive layer 62 are transparent photochromic powder, nano-scale conductive antistatic agent and organic silicon compatible coupling agent with two active functional groups of methyl group and phenyl group.

[0030] In another embodiment, the thickness of the photosensitive layer 62 is 1-10 μm.

[0031] In another embodiment, the nano-scale conductive antistatic agent includes silver nanowires and / or nano-indium tin oxide.

[0032] The invention also discloses a method for preparing the photosensitive film, which includes the following steps:

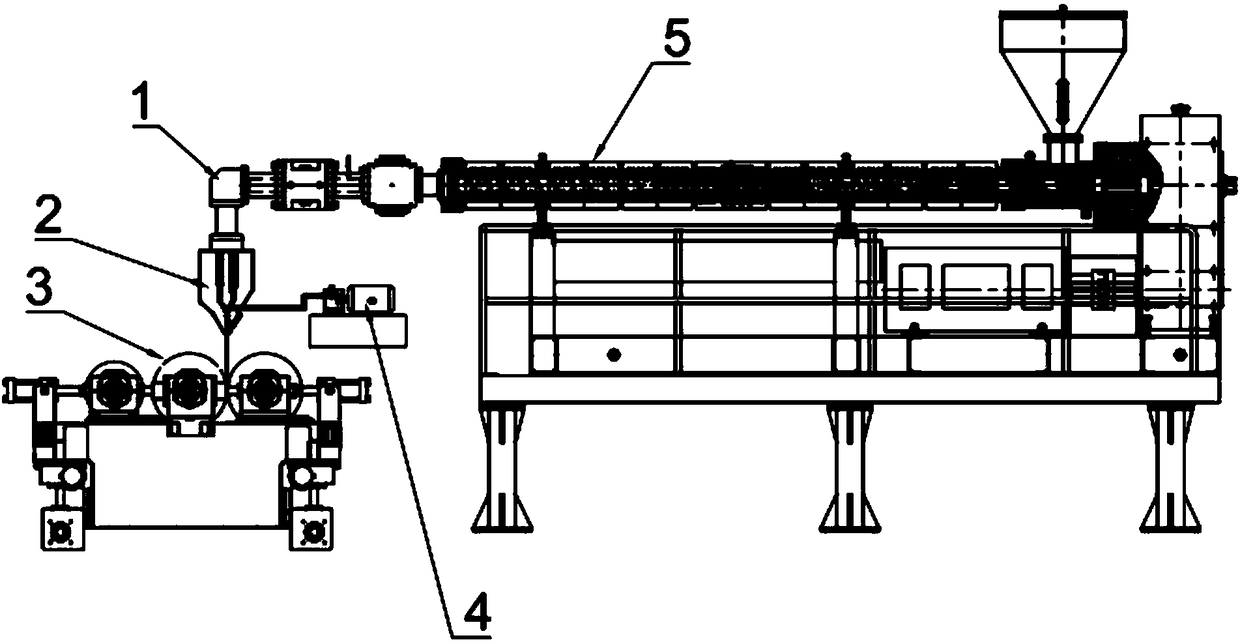

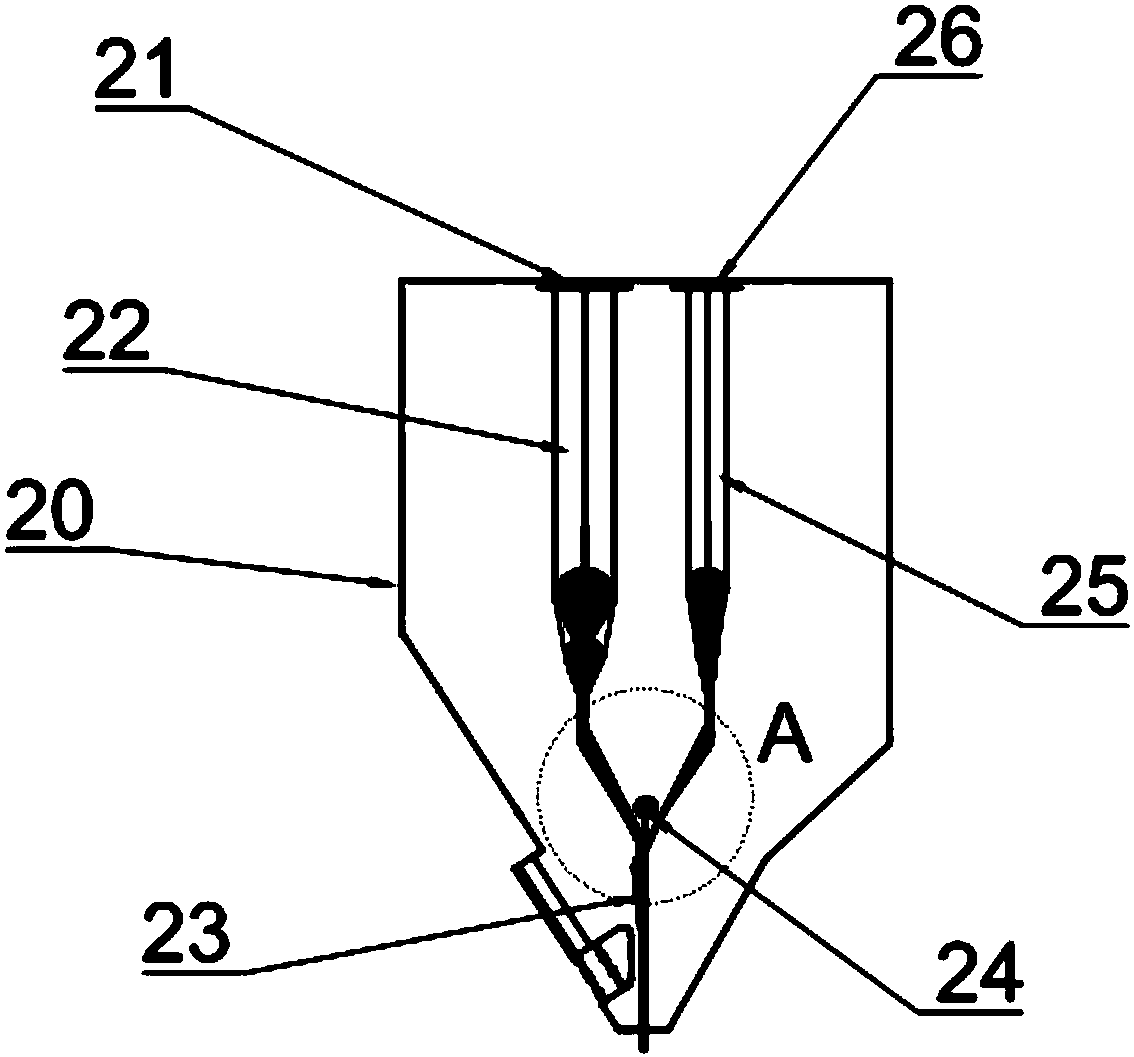

[0033] A, polycarbonate PC material and polymethyl methacrylate PMMA material are packed in two plastic extruders 5 respectively, the photosensitive layer materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com