Porous compound microorganism carrier and preparation method thereof

A microbial carrier and porous layer technology, applied in biological treatment devices, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of reduced beneficial effect of nitrogen removal, increased COD content, insufficient mechanical strength, etc., and is easy to promote and the effect of application, promotion of growth and reproduction, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14

[0071] According to the raw materials and formulations thereof shown in Table 1, the microbial carrier of the present invention is prepared according to the following preparation method.

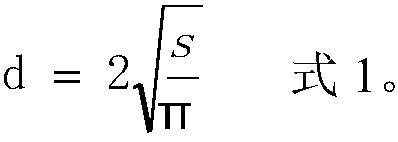

[0072] 1. Use a laser microhole puncher to punch holes in the non-biodegradable polymer resin porous layer B so that it contains micropores with diameters as shown in Table 1, and the hole density is as shown in Table 1;

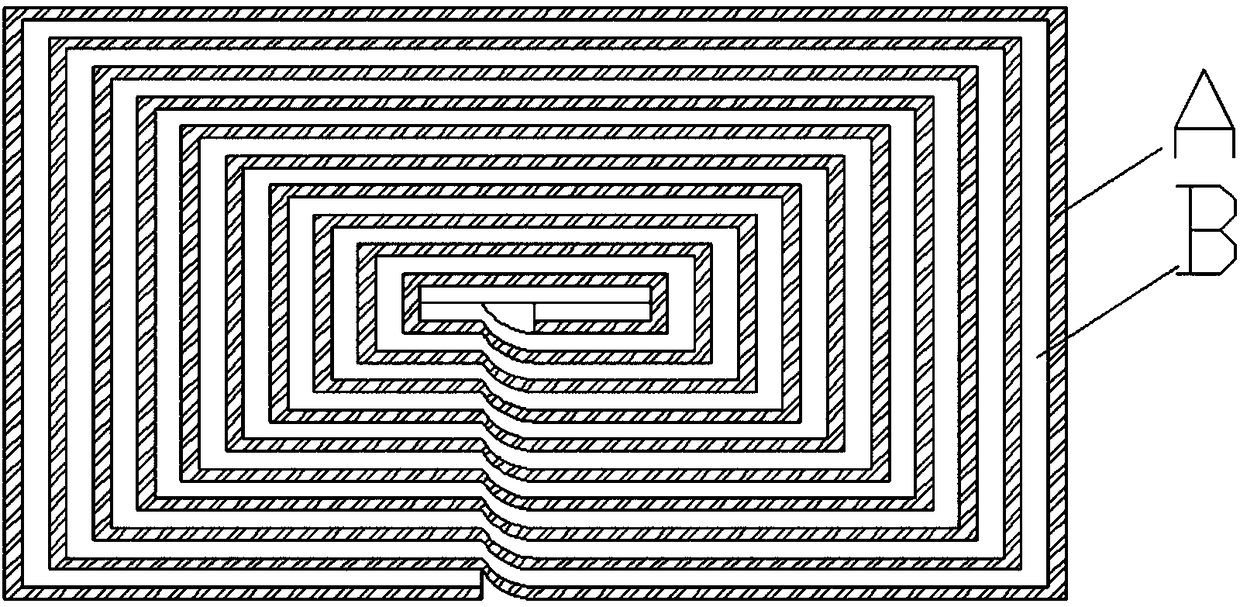

[0073] 2. Laminate X layer of biodegradable polymer resin porous layer A and Y layer of non-biodegradable polymer resin porous layer B;

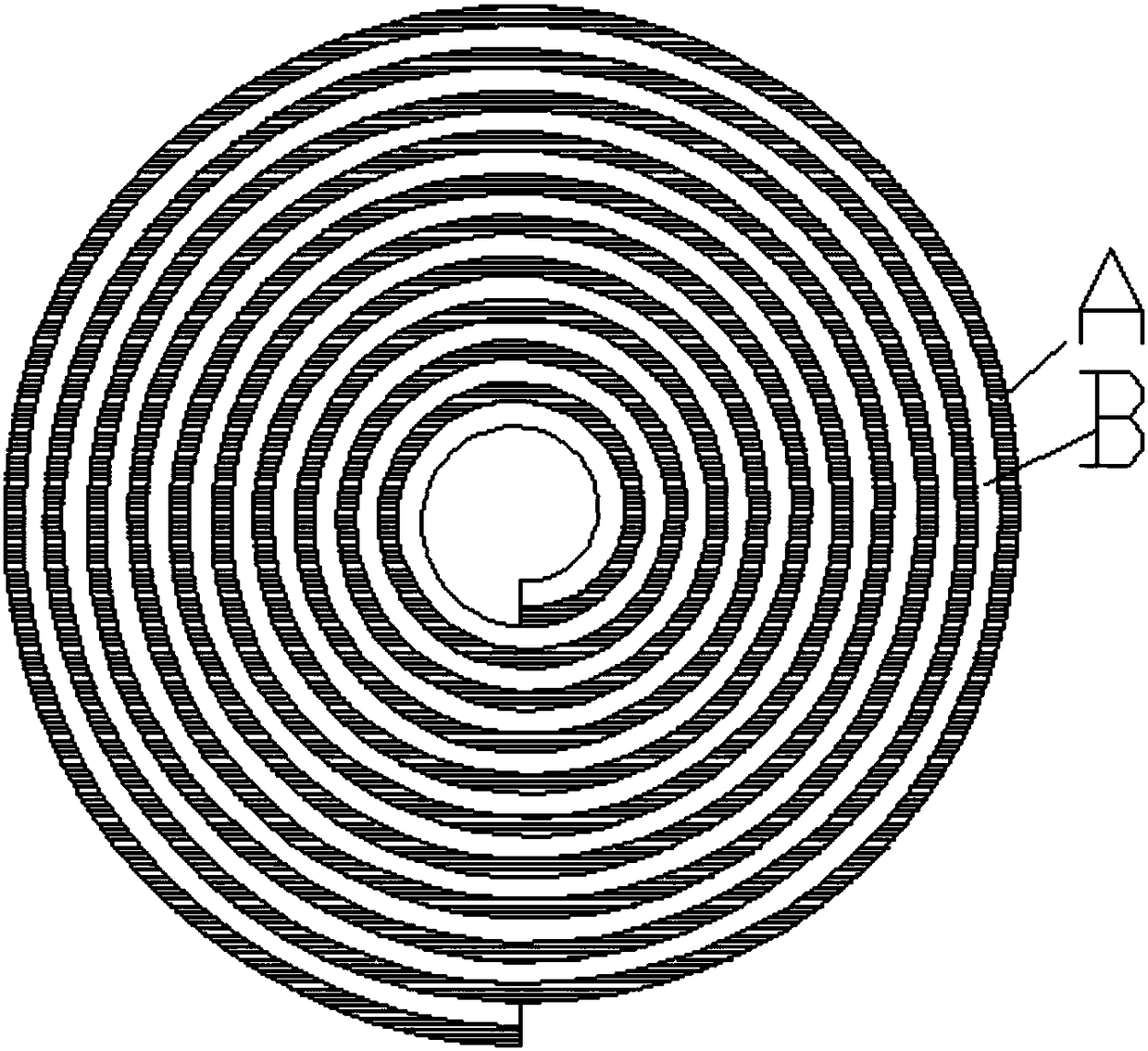

[0074] 3. The laminated multilayer film is wound into a roll, so that between two adjacent porous layers A, the maximum value Nm of the number of layers of the porous layer B is as shown in Table 1, with a length of 100 mm and a diameter of 60 mm;

[0075] 4. Hot pressing the roll-shaped object under the conditions of 80-120° C. and 0.5-4 MPa to obtain a block microbial carrier with a length of 100 mm×width of 60 mm×a thickness of 40 mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com