Method for preparing tocopherol succinate, and heating system

A technology of tocopheryl succinate and heating system, which is applied in the direction of steam generation method, steam generation, lighting and heating equipment, etc., which can solve the problem of loss of function, no longer having vitamin E biological activity, vitamin E product preparation, and inconvenient storage And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

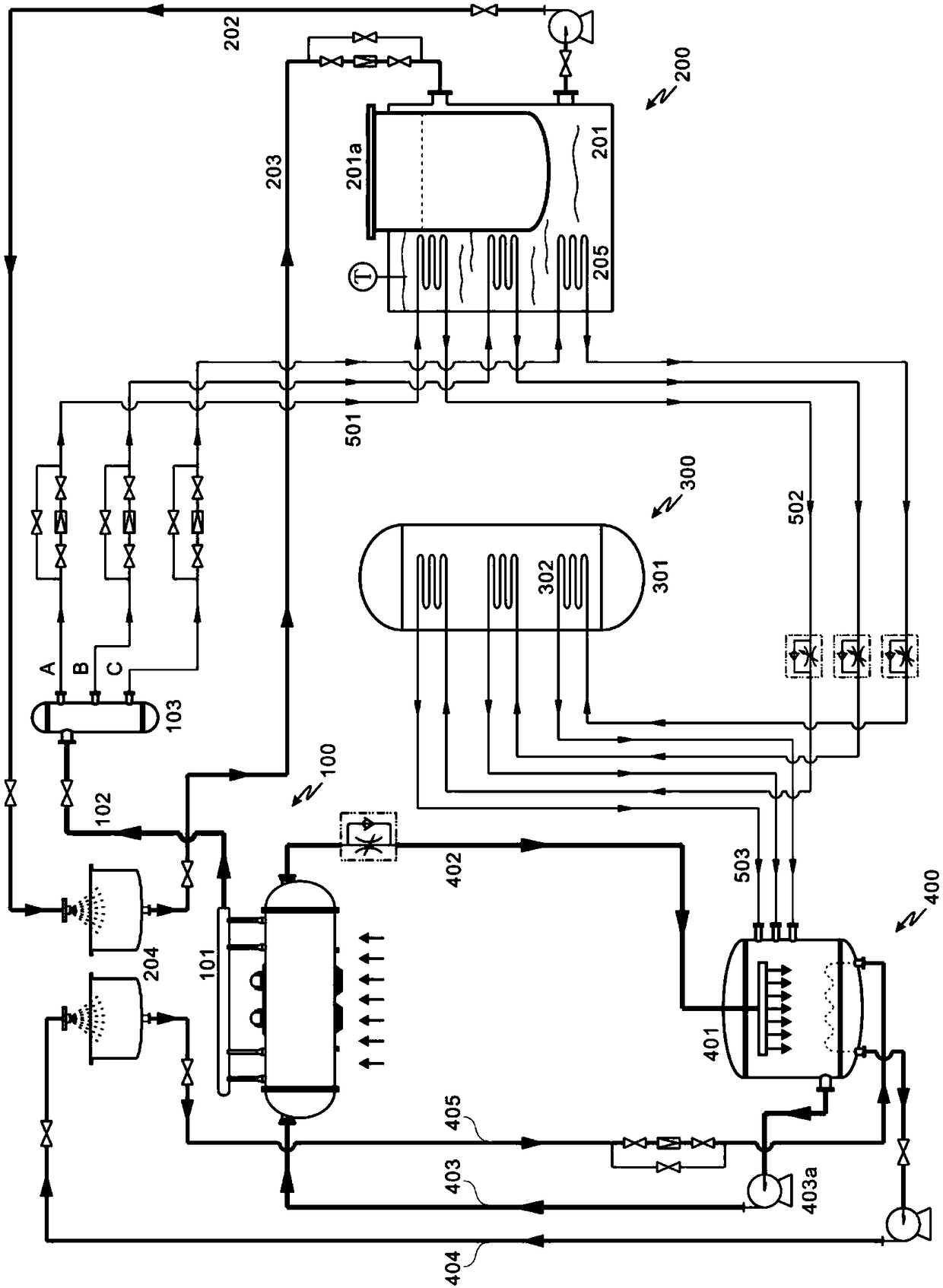

Method used

Image

Examples

Embodiment 1

[0026] Select synthetic tocopherol (the purity of tocopherol is 99.8%), add succinic anhydride (addition is added according to 2.5 times of the molar weight of tocopherol), then add pyridine (addition is that every kilogram of synthetic tocopherol adds 80ml), then at 45 The reaction was carried out at ℃ for 2.5h to obtain the crude product of natural tocopherol succinate.

[0027] The prepared crude natural tocopheryl succinate was crystallized with n-hexane, the amount of n-hexane / tocopheryl succinate was 7ml / g, and crystallized at 4°C for 20h.

[0028] It is calculated that the yield of the whole reaction is 96.8%, the esterification rate is 96.23%, the reaction process is mild and efficient, and the purity is 99.02% (yield=actual yield / theoretical yield).

Embodiment 2

[0030] Select synthetic tocopherol (the purity of tocopherol is 99.8%), add succinic anhydride (addition is added according to 2.5 times of the molar weight of tocopherol), then add pyridine (addition is that every kilogram of synthetic tocopherol adds 90ml), then at 50 The reaction was carried out at ℃ for 2 hours to obtain the crude product of natural tocopherol succinate.

[0031] The prepared crude natural tocopheryl succinate was crystallized with n-hexane, the amount of n-hexane / tocopheryl succinate was 7ml / g, and crystallized at 3°C for 18h.

[0032] After calculation, the yield of the whole reaction is 95.6%, the esterification rate is 95.89%, the reaction process is mild and efficient, and the purity is 98.07% (yield=actual yield / theoretical yield).

Embodiment 3

[0034] Select synthetic tocopherol for use (tocopherol purity is 99.8%), add succinic anhydride (addition is added according to 2.5 times of the molar weight of tocopherol), then add pyridine (addition is that every kilogram of synthetic tocopherol adds 100ml), then at 40 The reaction was carried out at ℃ for 2.5h to obtain the crude product of natural tocopherol succinate.

[0035] The prepared crude natural tocopheryl succinate was crystallized with n-hexane, the amount of n-hexane / tocopheryl succinate was 6ml / g, and crystallized at 4°C for 18h.

[0036] After calculation, the yield of the whole reaction is 95.0%, the esterification rate is 96.08%, the reaction process is mild and efficient, and the purity is 98.67% (yield=actual yield / theoretical yield).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com