Method for extracting polysaccharides from ganoderma lucidum mycelia

A technology of Ganoderma lucidum mycelium and Ganoderma lucidum polysaccharide, which is applied in the field of microorganisms, can solve the problems of difficult dissolution, difficulty of Ganoderma lucidum mycelium, and destruction of polysaccharide activity, etc., and achieves the effects of easy breakage, short cultivation period and simple cultivation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

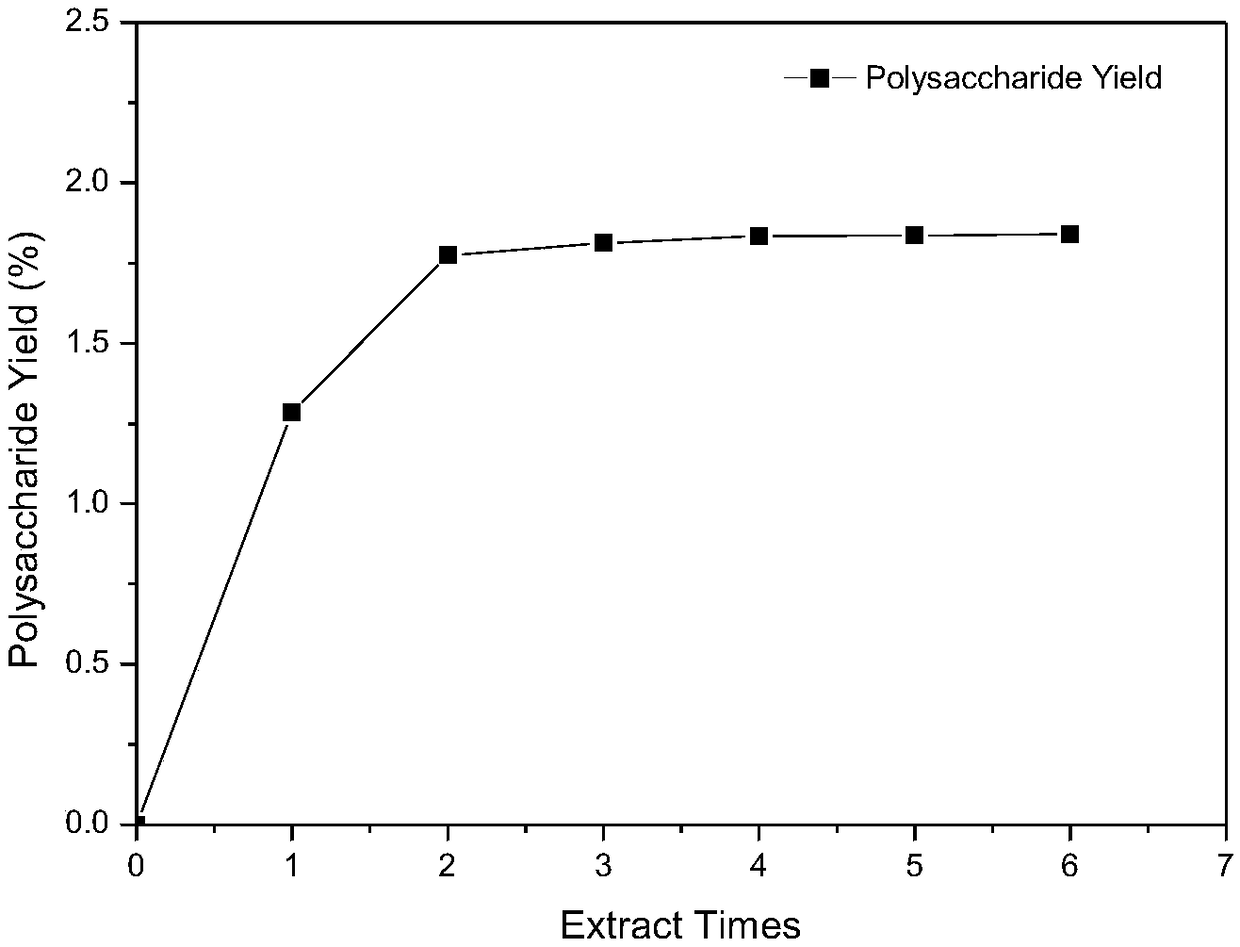

[0043] Determination of total polysaccharide content in embodiment 1 Ganoderma lucidum mycelium

[0044] 1. The Ganoderma lucidum mycelia fermentation broth is centrifuged to obtain the Ganoderma lucidum mycelium, and the Ganoderma lucidum mycelium is dried in an oven at 60°C;

[0045] 2. Take 10g of Ganoderma lucidum mycelium, add 100ml of water in sequence according to the ratio of 1:10, mix well and form a mixture of Ganoderma lucidum mycelia;

[0046] 3. Place the mixture in hot water at 80°C, stir, and ultrasonically treat for 20 minutes;

[0047] 4. Centrifuge after ultrasonic treatment, take out the supernatant, and detect the polysaccharide content of Ganoderma lucidum according to the phenol-sulfuric acid method;

[0048] 5. The precipitate after centrifugation was repeated 5 times according to steps 2 to 4, and the polysaccharide was extracted 6 times in total;

[0049] 6. Calculate the total content of polysaccharides in the mycelium of Ganoderma lucidum according...

Embodiment 2

[0061] 1) Ganoderma lucidum mycelium is obtained by centrifuging the fermentation liquid of ganoderma lucidum mycelia, and the mycelia of ganoderma lucidum is dried in an oven at 60° C. for later use;

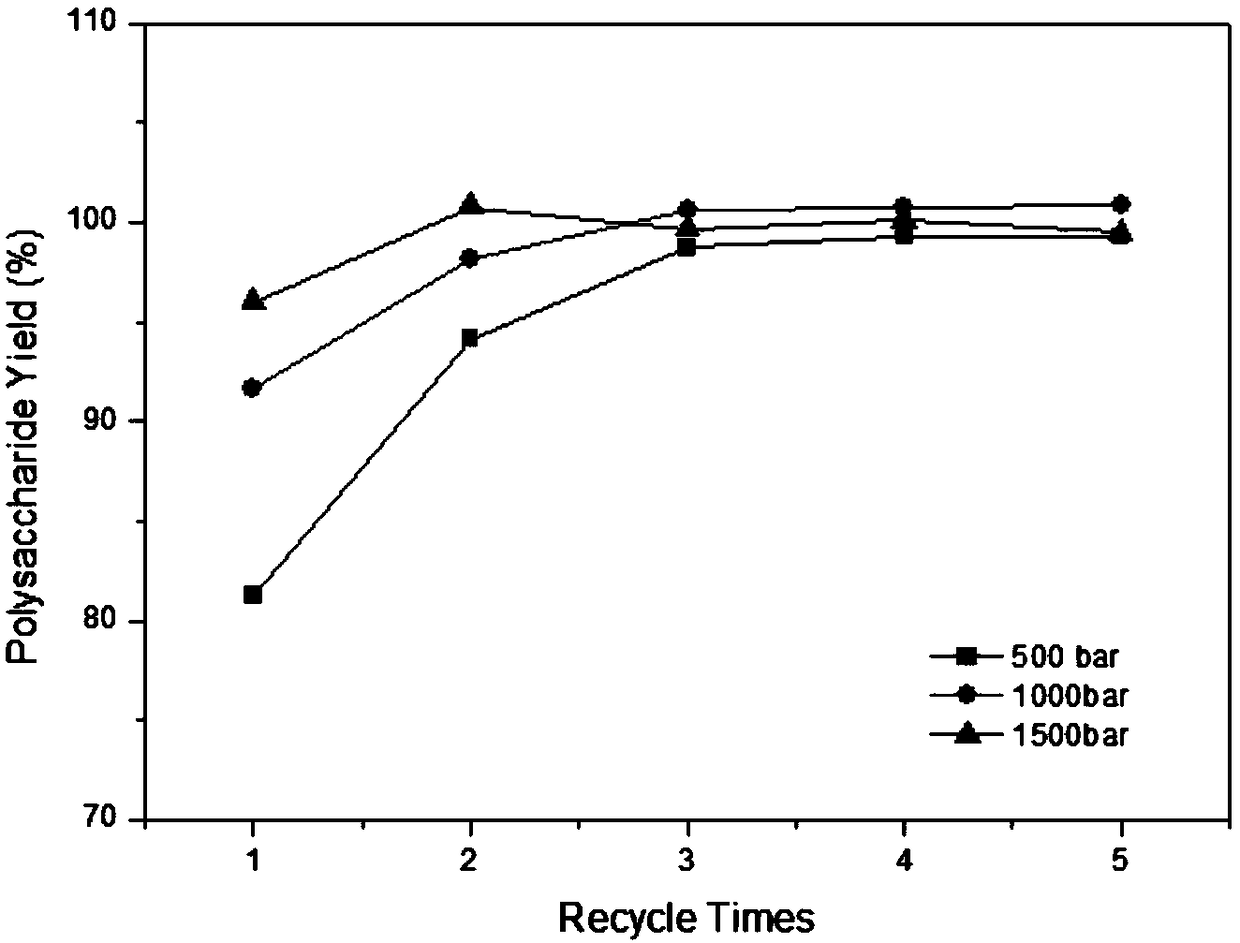

[0062] 2) Take 100g of Ganoderma lucidum mycelium, add 3000ml of water, use a high-speed homogenizer to homogenize at a speed of 5000rpm for 5 minutes, and mix evenly to form a mixed liquid of Ganoderma lucidum mycelia;

[0063] 3) The pressure of the high-pressure homogenizer is set to 500 bar, and the number of cycles is 1 time;

[0064] 4) Centrifuge at high speed to obtain supernatant.

Embodiment 3

[0066] 1) Ganoderma lucidum mycelium is obtained by centrifuging the fermentation liquid of ganoderma lucidum mycelia, and the mycelia of ganoderma lucidum is dried in an oven at 60° C. for later use;

[0067] 2) Take 100g of Ganoderma lucidum mycelium, add 3000ml of water, use a high-speed homogenizer to homogenize at a speed of 5000rpm for 5 minutes, and mix evenly to form a mixed liquid of Ganoderma lucidum mycelia;

[0068] 3) The pressure of the high-pressure homogenizer is set to 500 bar, and the number of cycles is 2 times;

[0069] 4) Centrifuge at high speed to obtain supernatant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com