Segmented polymer FPEG-CO-CA modified CA filter membrane and preparation method thereof

A FPEG-CO-CA, block polymer technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the complex method of synthesizing modified CA filter membrane, the metal salt catalyst is not easy to remove, and the CA filter membrane is hydrophobic It has the advantages of excellent oil resistance and anti-pollution ability, wide application range, enhanced hydrophilicity and oleophobicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The block polymer FPEG-CO-CA modified CA filter membrane is prepared by the following steps:

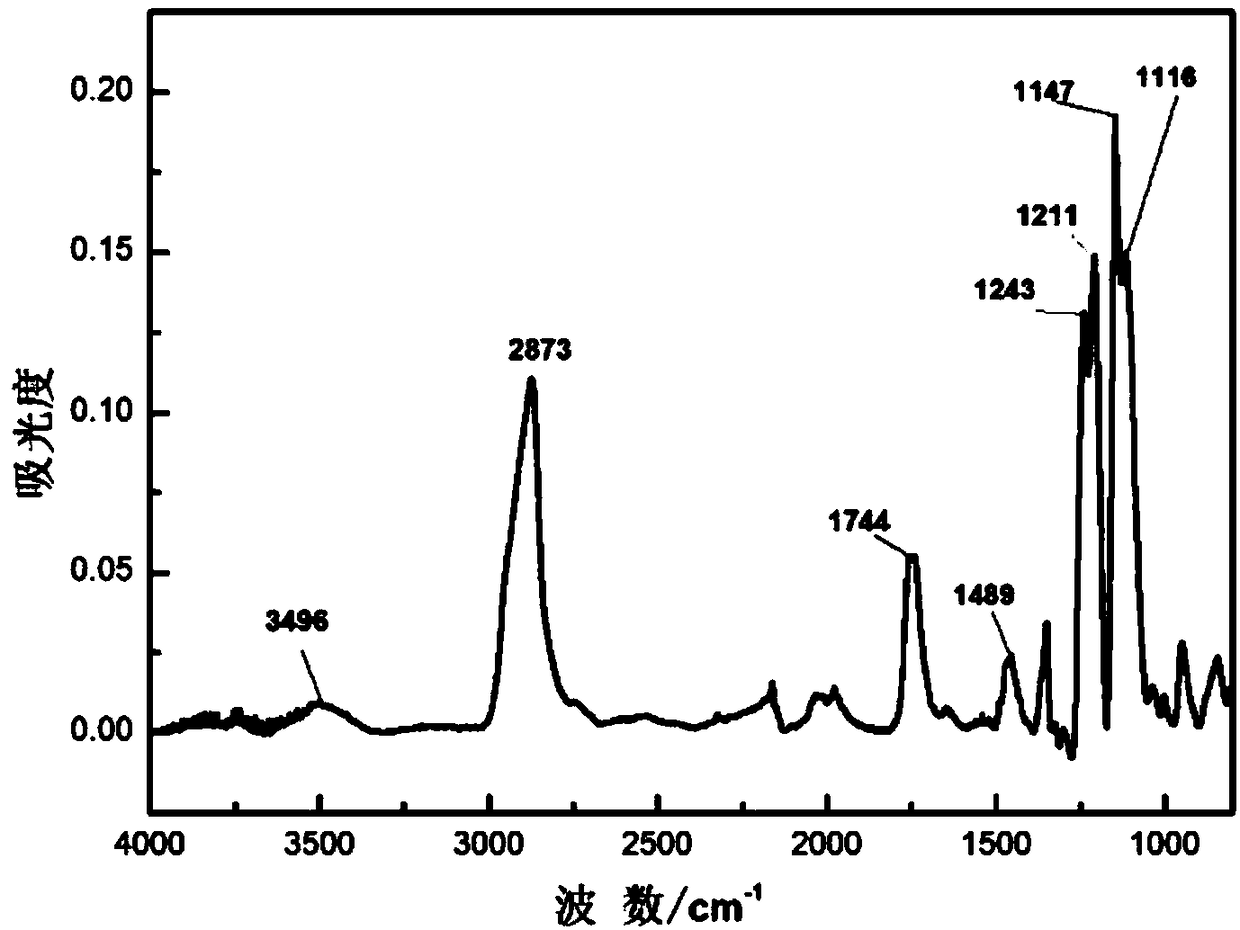

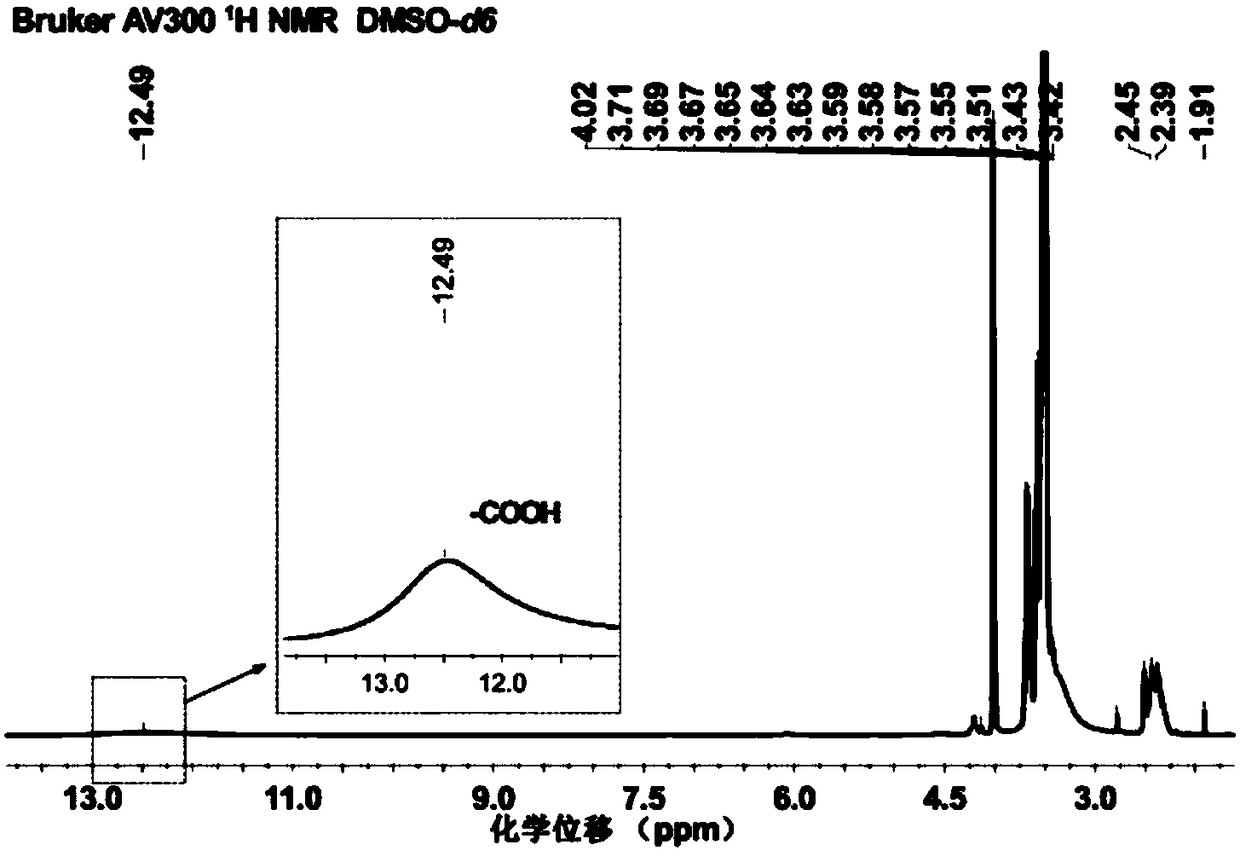

[0045] 1) Perfluoroalkyl-polyethylene glycol (FPEG) is oxidized with 2,2,6,6-tetramethylpiperidine nitrogen oxide (TEMPO) to obtain perfluoroalkyl-polyethylene glycol carboxylic acid (FPEG-COOH);

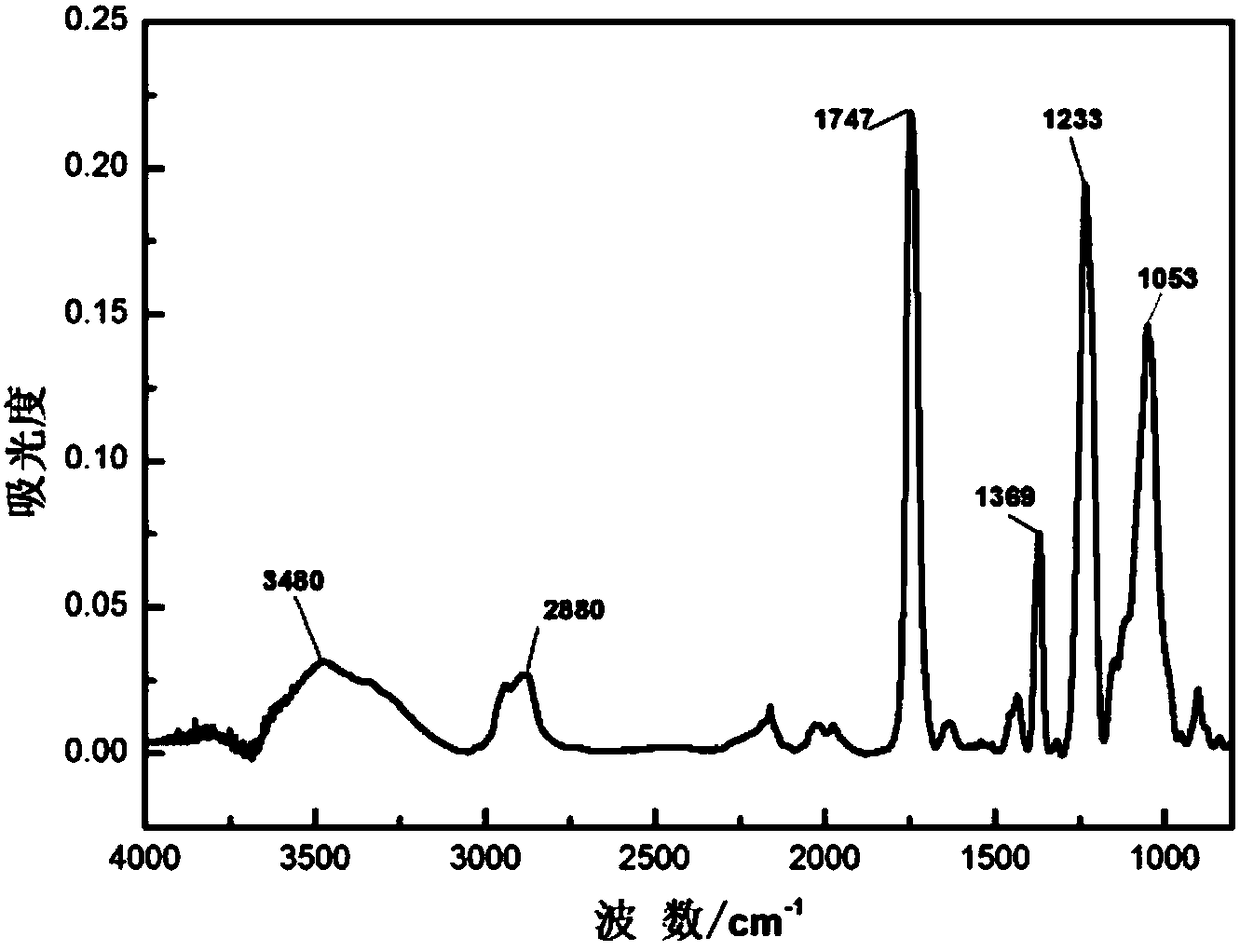

[0046] 2) Esterification of cellulose acetate (CA) with perfluoroalkyl-polyethylene glycol carboxylic acid (FPEG-COOH) to synthesize block polymer FPEG-CO-CA;

[0047] 3) The cellulose acetate (CA) with a mass ratio of 7:3 and the block polymer FPEG-CO-CA were respectively placed in a vacuum drying oven at 60°C for 12 hours, and the solvent N,N-di Methylacetamide (DMAc) was used for drying; the dried CA and FPEG-CO-CA were dissolved in the dried DMAc in a certain proportion, and mechanically stirred at a speed of 200r / min at a temperature of 40°C for 12-36h , forming a casting solution; the molecular weight of cellulose acetate (CA) is about 30000, wherein the acetyl group content...

Embodiment 2

[0051] The block polymer FPEG-CO-CA modified CA filter membrane is prepared by the following steps:

[0052] 1) Perfluoroalkyl-polyethylene glycol (FPEG) is oxidized with 2,2,6,6-tetramethylpiperidine nitrogen oxide (TEMPO) to obtain perfluoroalkyl-polyethylene glycol carboxylic acid (FPEG-COOH);

[0053] 2) Esterification of cellulose acetate (CA) with perfluoroalkyl-polyethylene glycol carboxylic acid (FPEG-COOH) to synthesize block polymer FPEG-CO-CA;

[0054] 3) The cellulose acetate (CA) with a mass ratio of 9:1 and the block polymer FPEG-CO-CA were respectively placed in a vacuum drying oven at 60°C for 36 hours, and the solvent N,N-di Methylacetamide (DMAc) was used for drying; the dried CA and FPEG-CO-CA were dissolved in the dried DMAc in a certain proportion, and mechanically stirred at a speed of 500r / min for 36h at a temperature of 80°C to form Casting solution; the molecular weight of cellulose acetate (CA) is about 50000, wherein the acetyl content is 40wt%, an...

Embodiment 3

[0058] The block polymer FPEG-CO-CA modified CA filter membrane is prepared by the following steps:

[0059] 1) Perfluoroalkyl-polyethylene glycol (FPEG) is oxidized with 2,2,6,6-tetramethylpiperidine nitrogen oxide (TEMPO) to obtain perfluoroalkyl-polyethylene glycol carboxylic acid (FPEG-COOH);

[0060] 2) Esterification of cellulose acetate (CA) with perfluoroalkyl-polyethylene glycol carboxylic acid (FPEG-COOH) to synthesize block polymer FPEG-CO-CA;

[0061] 3) The cellulose acetate (CA) with a mass ratio of 5:1 and the block polymer FPEG-CO-CA were respectively placed in a vacuum drying oven at 60°C for 50 h, and the solvent N,N-di Methylacetamide (DMAc) was used for drying; the dried CA and FPEG-CO-CA were dissolved in the dried DMAc in a certain proportion, and mechanically stirred at a speed of 380r / min for 25h at a temperature of 60°C to form Casting liquid; the molecular weight of cellulose acetate (CA) is about 40000, wherein the content of acetyl group is 39wt%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Oil contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com