Baijiu processing technology

A processing technology and liquor technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of long aging time of liquor, and achieve the effects of strengthening oxidation, increasing dissolved oxygen, and increasing redox potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

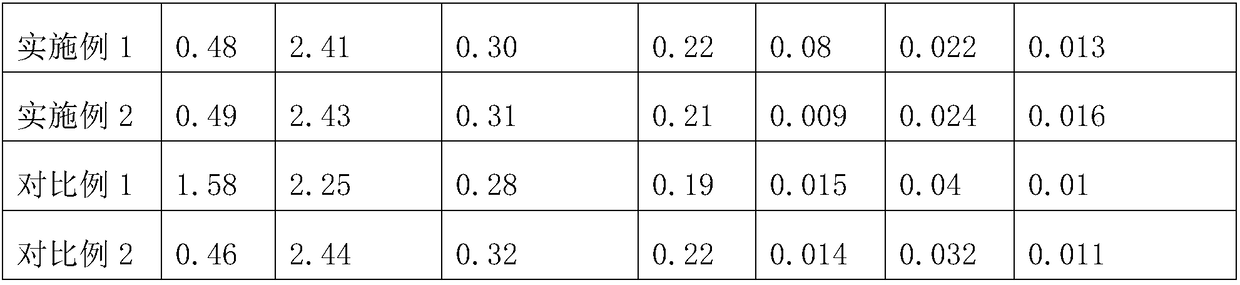

Embodiment 1

[0017] Embodiment 1: a kind of liquor processing technology, comprises the following steps:

[0018] Step 1. Pour the freshly distilled liquor into the pre-sterilized wine barrel, the liquid level of the liquor is 3 to 5 cm away from the mouth of the barrel, and put the liquor in a cold cellar at -8°C for 1 to 2 days of cold treatment;

[0019] Step 2, adding corn cob powder, glucose and mushroom powder to the liquor in step 1, and storing it in an irradiation environment at 23°C for 2-3 days;

[0020] Step 3, in the middle of the white wine in step 2, add the acetic acid bacterium colony that mixes with red sulfur bacterial classification, wherein the inoculation amount of red sulfur bacterial classification is 4.8ml / kg wine liquid, and the inoculum amount of acetic acid bacterium colony is 1.47ml / kg wine liquid, After adding walnut shell powder and diatomaceous earth during stirring, seal the barrel after stirring evenly and place the barrel in a dark environment at 18-22°C ...

Embodiment 2

[0022] Embodiment 2: a kind of liquor processing technology, comprises the following steps:

[0023] Step 1. Pour the freshly distilled liquor into the pre-sterilized wine barrel, the liquid level of the liquor is 3-5cm away from the mouth of the barrel, and put the liquor in a cold cellar at 6°C for 1-2 days of cold treatment;

[0024] Step 2, adding corn cob powder, ribose and mushroom powder to the liquor in step 1, and storing it in an irradiation environment at 25°C for 2-3 days;

[0025] Step 3, in the middle of the white wine in step 2, add the acetic acid bacterium colony that mixes with green sulfur bacteria classification, wherein the inoculation amount of green sulfur bacteria classification is 5.5ml / kg liquor, the inoculum amount of acetic acid colony is 1.84ml / kg liquor, When stirring, add walnut shell powder and diatomaceous earth, stir evenly, seal the barrel, and place the barrel in a dark environment at 18-22°C for 4-6 days, then filter out the solids;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com