Thick-wall large-diameter X80M pipeline clean steel and smelting method thereof

A smelting method and large-diameter technology, applied in the field of metallurgy to achieve the effect of facilitating slag premelting, reducing desulfurization pressure and improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A clean steel smelting method for a thick-walled large-diameter X80M pipeline provided in this embodiment includes the following steps:

[0025] S1. The desulfurization station uses lime and magnesium powder for composite desulfurization. After desulfurization, the slag is cleaned. S≤0.0020% in molten iron, and S≤0.0010% after converter;

[0026] S2. Steelmaking adopts the process route of BOF→LF furnace refining→RH refining→continuous casting; converter tapping temperature is 1660℃~1680℃; converter tapping adopts pre-melted refining slag + active lime for slagging;

[0027] S3. After the molten steel reaches the LF furnace, heat up the slag. The bottom blowing argon gas flow rate is 300Nl / min~500Nl / min during the temperature rise process. Add aluminum wire appropriately according to the slag condition, and then carry out desulfurization operation after reaching the white slag and submerging the arc. Lime is added Volume 1Kg / t, aluminum wire 0.1Kg / t, bottom blowing argo...

Embodiment 2~ Embodiment 6

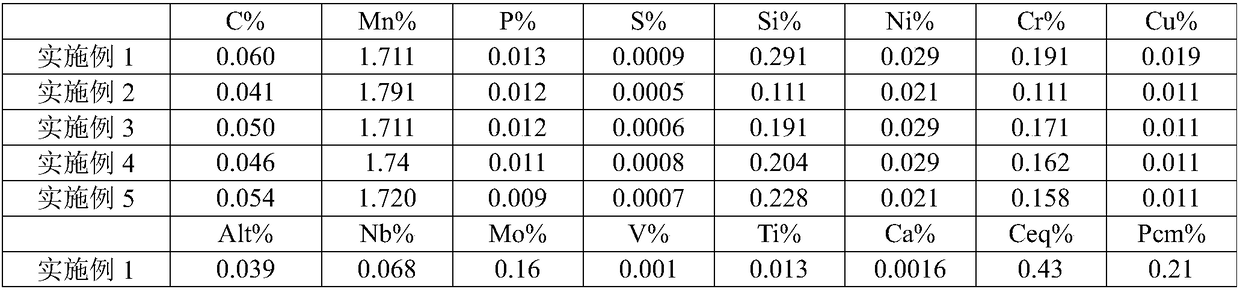

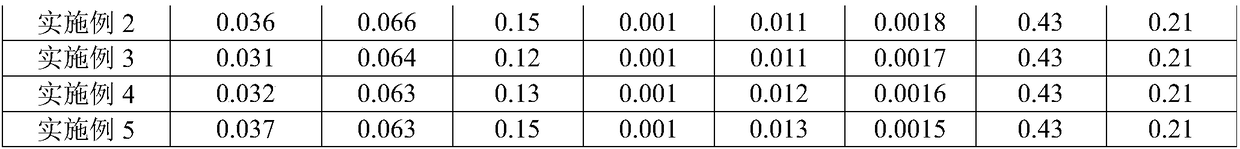

[0031] A thick-walled and large-diameter X80M pipeline clean steel provided in Examples 2 to 6 is produced by the production method described in Example 1. The chemical composition and mass percentage are shown in Table 1, and the parameter control is shown in Table 2. The test results are shown in Table 3:

[0032] Table 1

[0033]

[0034]

[0035] Table 2

[0036] furnace number

Vacuum

vacuum time

calcium treatment

Stirring time

Large amount of surplus steel

superheat

Example 1

2mbar

20min

180m

20min

3t

39℃

Example 2

2mbar

20min

160m

20min

2t

37℃

Example 3

2mbar

20min

160m

20min

3t

36℃

Example 4

2mbar

20min

160m

20min

2t

35℃

Example 5

2mbar

18min

160m

20min

3t

38℃

[0037] table 3

[0038]

steel type

Inspection quantity / piece

Level 1.5 qualified quantity / piece

1.5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com