Electrospinning material receiving device and manufacturing device for electrospinning

A receiving device and electrospinning technology, applied in the field of spinning manufacturing, can solve problems such as restricting cell migration and penetration, and achieve the effects of easy rotation control, avoiding uneven distribution of fibers, and reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

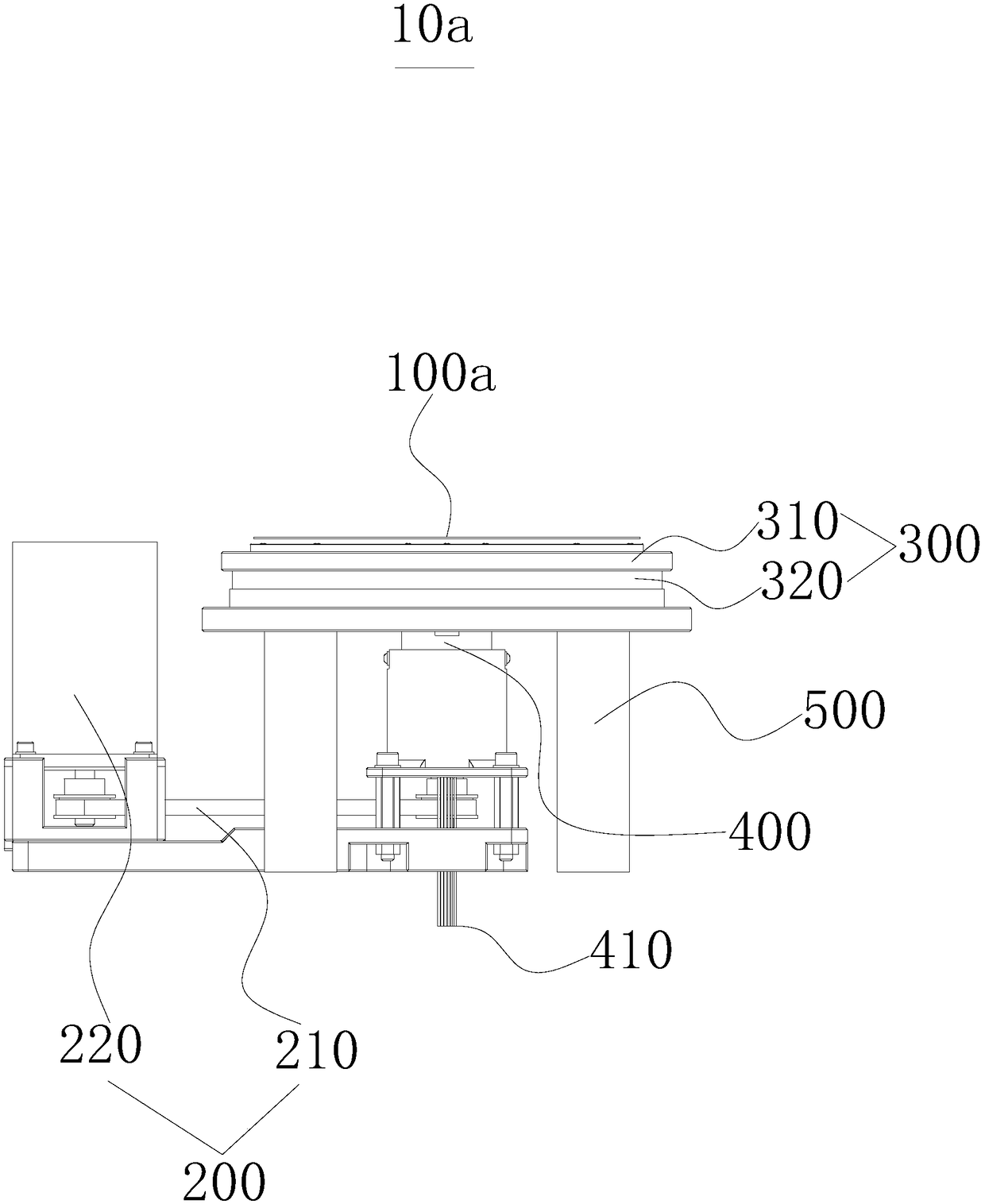

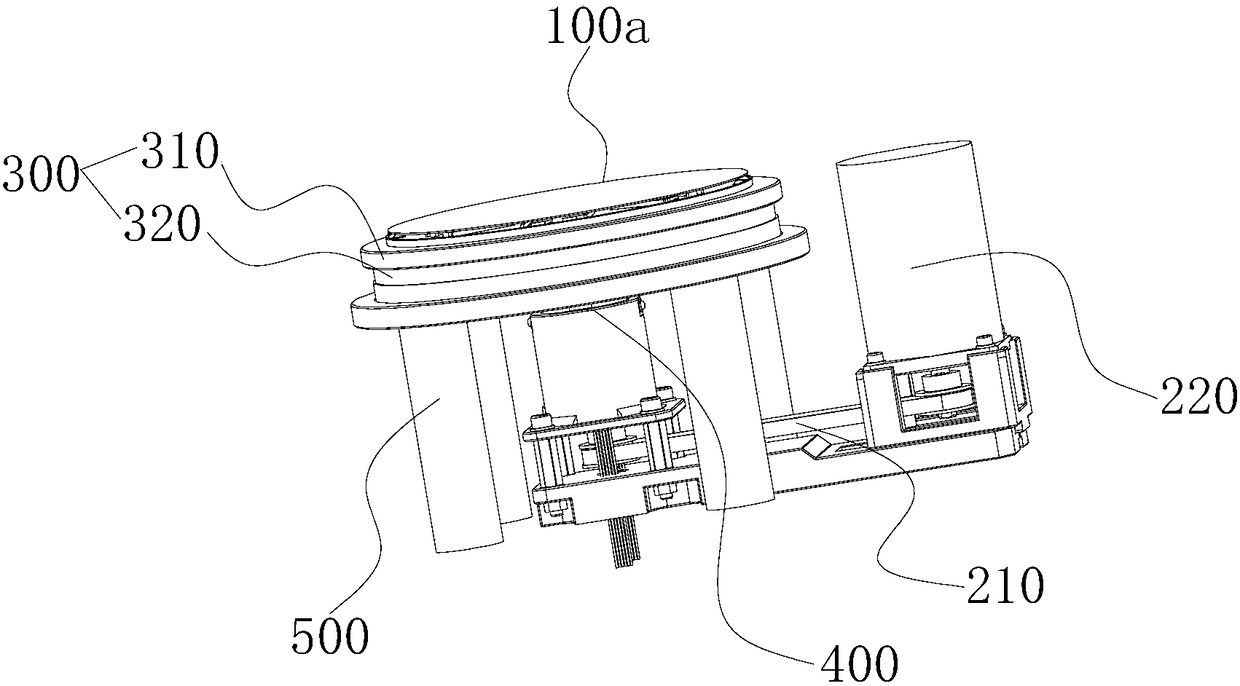

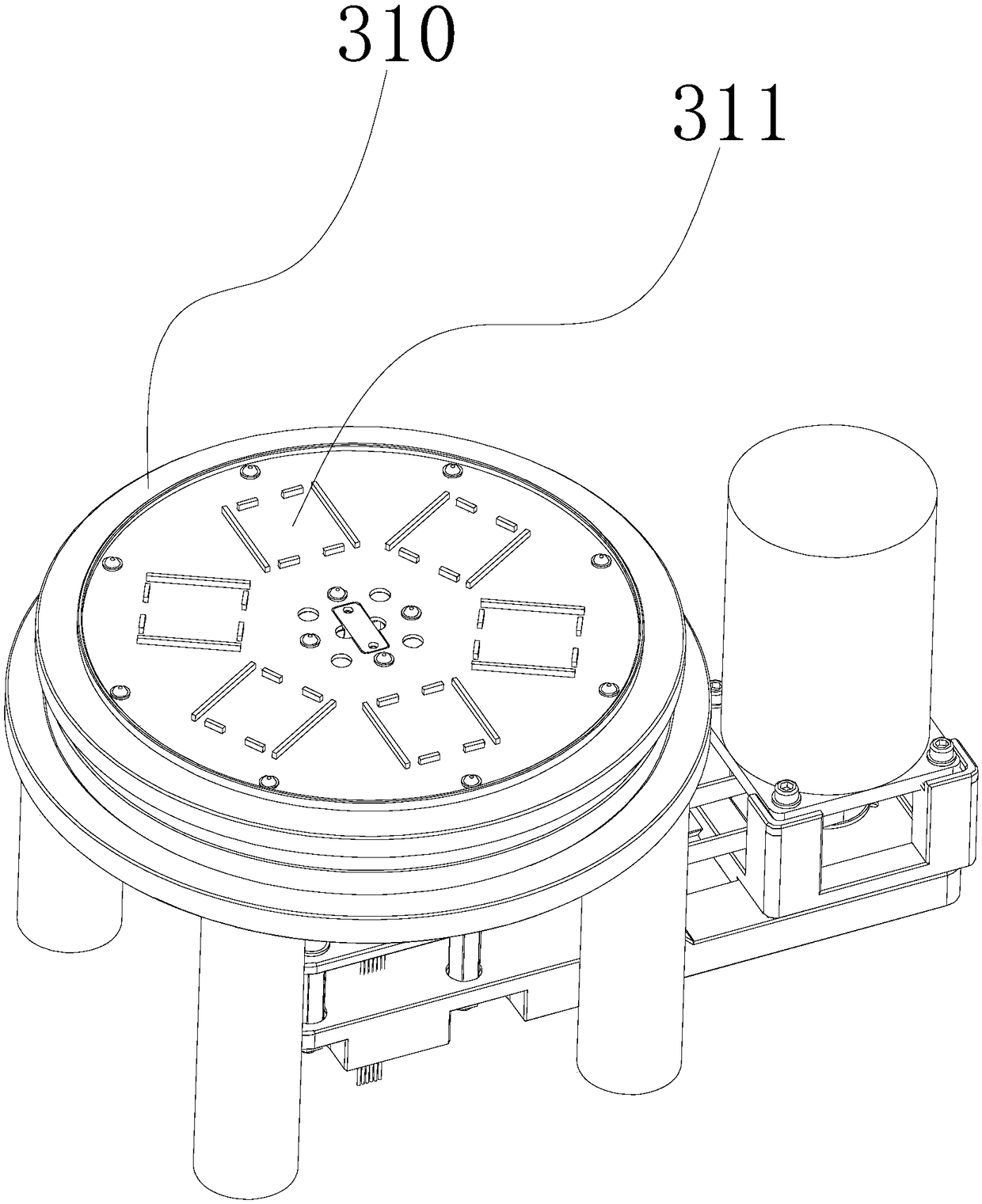

[0028] See attached figure 1 And figure 2 This embodiment provides an electrospinning material receiving device 10a, which includes: a receiving plate 100a, a driving device 200 for driving the receiving plate 100 to rotate, and a refrigerating device for cooling the receiving plate 110.

[0029] The receiving plate 100a rotates under the driving of the driving device 200, so that it can uniformly receive the fibers ejected from the nozzles in different directions at the same time, realize bi-component or multi-component electrostatic spinning, and avoid fiber distribution due to the same kind of charge repulsion. Evenly. At the same time, the receiving plate 100a is cooled by the refrigerating device, so that the surface of the receiving plate 100a is low temperature, which in turn causes the water vapor in the air to condense during the spinning process to form ice crystals, which are used as porogens and supporting materials to make the electrospun fiber vertical Direction st...

no. 2 example

[0046] See attached Figure 5 An electrospinning material receiving device 10b improved in this embodiment, the receiving plate 100b is a hollow structure with a refrigerating cavity inside, and the transmission mechanism 210 is connected to the receiving plate through a hydroelectric hybrid conductive slip ring 400. The water interface of the ring 400 is connected to the refrigeration cavity. In this embodiment, the structure of the receiving plate 100 refers to the structure of the heat dissipation plate 300 in the first embodiment, and other structures refer to the first embodiment. That is, compared with the first embodiment, this embodiment removes the In this embodiment, the upper surface of the first heat dissipation plate 310 in the first embodiment is set as a smooth surface as the receiving surface. In this embodiment, liquid nitrogen is directly introduced into the refrigeration cavity through an external refrigeration cycle system for refrigeration operation, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com