Road-surface microwave deicing method based on high-dielectric-constant material covering

A high dielectric constant material, microwave technology, applied in snow surface cleaning, cleaning methods, construction and other directions, can solve the problems of high cost, high technical difficulty, low efficiency, etc., to achieve low production cost, good application prospects, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, the present invention will be further clarified with reference to the accompanying drawings and specific implementation cases. It should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. After reading the present invention, those skilled in the art will understand various aspects of the present invention. Modifications of the price form all fall within the scope defined by the appended claims of this application.

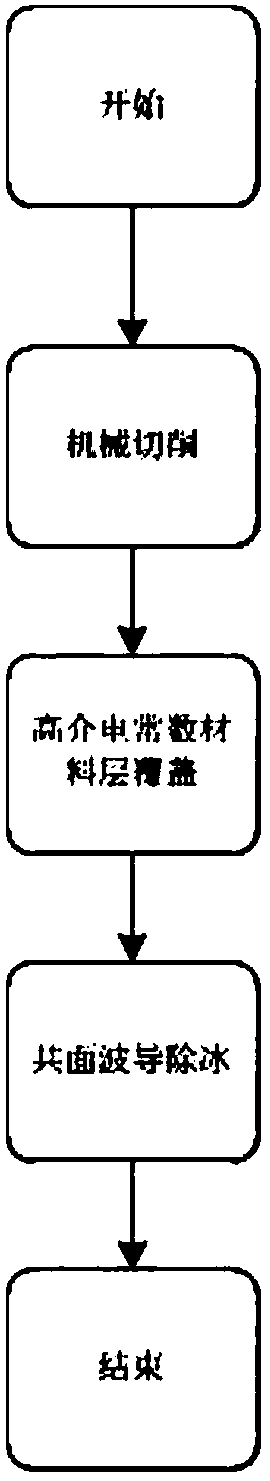

[0025] Comprehensive figure 1 The deicing process of the present invention is as follows:

[0026] Step 1, mechanical cutting.

[0027] During snowfall, the snow thickness of the road area in northern China can reach 5cm~15cm. Cars are prone to accidents under this kind of road conditions. If the road area snow cannot be dealt with in time, the snow will be frozen at night and daylight. If the layer becomes ice, the accident rate will be greatly increased. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com