Concave-convex meshing pure rolling spiral bevel gear mechanism for cross shaft transmission

A cross-axis, pure rolling technology, which is applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the plastic deformation of the tooth surface, cannot realize the movement and power transmission of two orthogonal axes in the plane, and cannot be used Conventional power and high-speed heavy-duty transmission and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

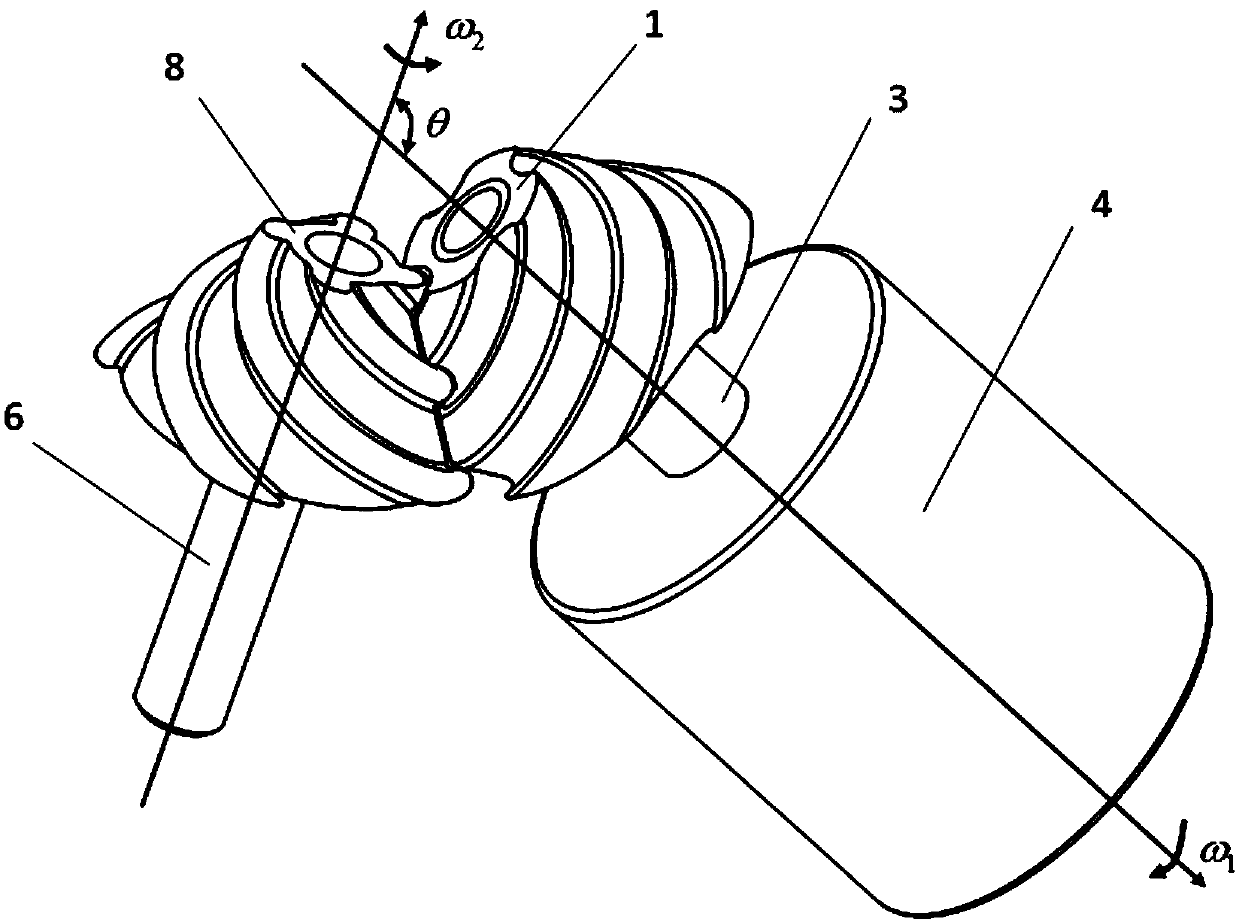

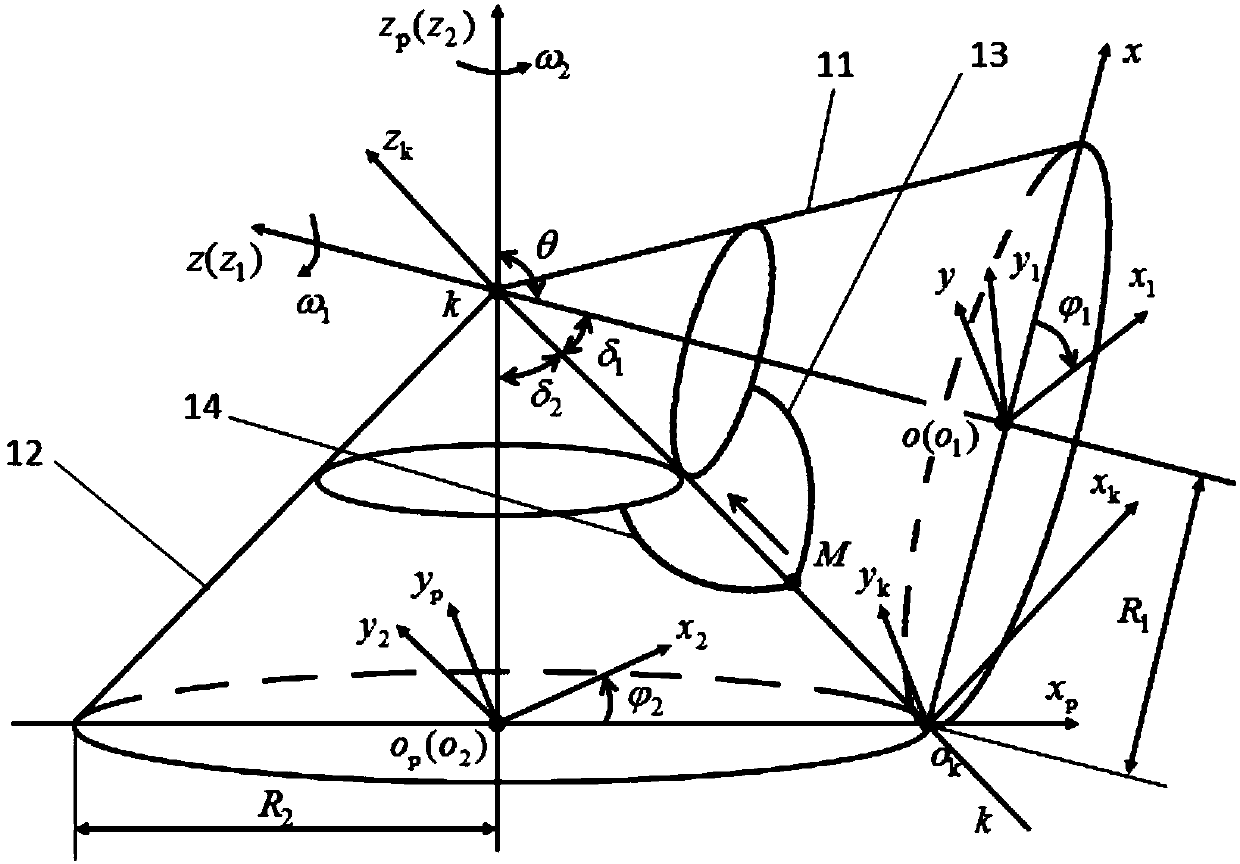

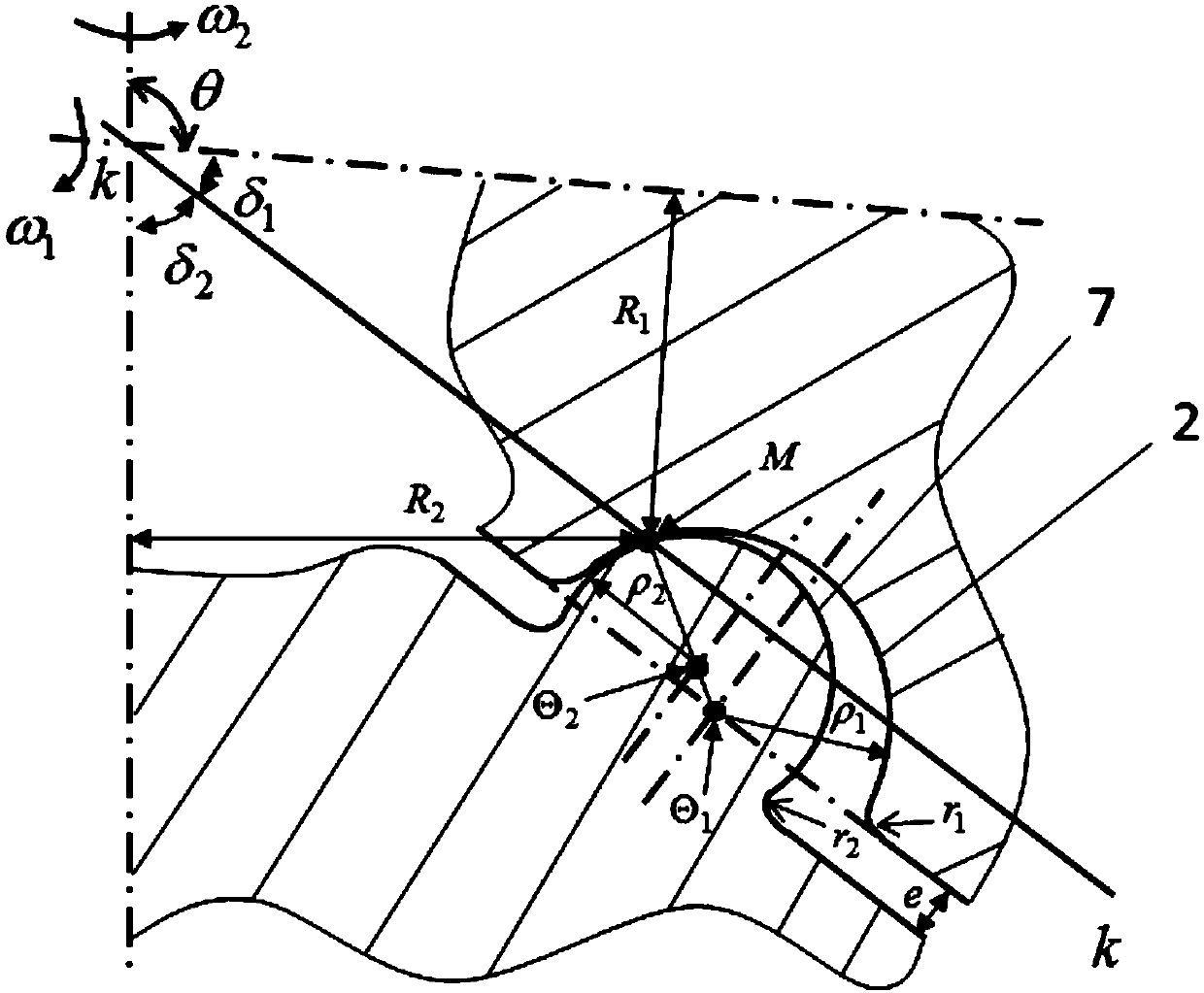

[0116] The present invention provides a concave-convex meshing pure rolling bevel gear mechanism for cross shaft transmission, which is applied to the transmission with a transmission ratio of 1 between two cross shafts in a plane, and its structure is as follows figure 1 As shown, it includes a small wheel 1 and a large wheel 8, the small wheel 1 and the large wheel 8 form a pair of transmission pairs, the small wheel 1 is connected to the input shaft 3 through the small wheel center hole 15, and the large wheel 8 is connected to the The wheel center hole 16 is connected to the output shaft 6, that is, the large wheel 8 is connected with the driven load through the output shaft 6; the axes of the small wheel 1 and the large wheel 8 intersect, and the small wheel 1 and the large wheel 8 The included angle between the angular velocity vectors is θ, and θ=2π / 3 radians (rad) in this example. figure 2 It is a schematic diagram of the spatial meshing coordinate system of the conca...

Embodiment 2

[0215] The concave-convex meshing pure rolling bevel gear mechanism for cross shaft transmission of the present invention is applied to the speed-up transmission between two vertical cross shafts, at this time θ=π / 2 radians (rad). like Figure 10 As shown, the large wheel 8 is used to connect the input shaft 3 through the center hole 16 of the large wheel, and the small wheel 1 is connected to the output shaft 6 through the center hole 15 of the small wheel, that is, the small wheel 1 is connected to the driven load through the output shaft 6; the small wheel 1 The axes of the bull wheel 8 are perpendicular to each other, and their angular velocity angle at this moment is θ=π / 2 radians (rad). In this embodiment, there are eight spiral arc teeth 7 on the bull wheel 8, and four spiral arc grooves 2 on the small wheel 1. When the input shaft 3 drives the bull wheel 8 to rotate, the design coincidence degree ε=2. Because when the big wheel 8 and the small wheel 1 are installed, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com