Device and method for measuring microscopic adhesion among hydrate particles in gas phase system

A hydrate and adhesion technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of high safety performance requirements of devices, expensive equipment, low operability, etc., to prevent external dust and water vapor from entering The effect of operating environment, keeping relatively clean and dry, and facilitating experimental operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

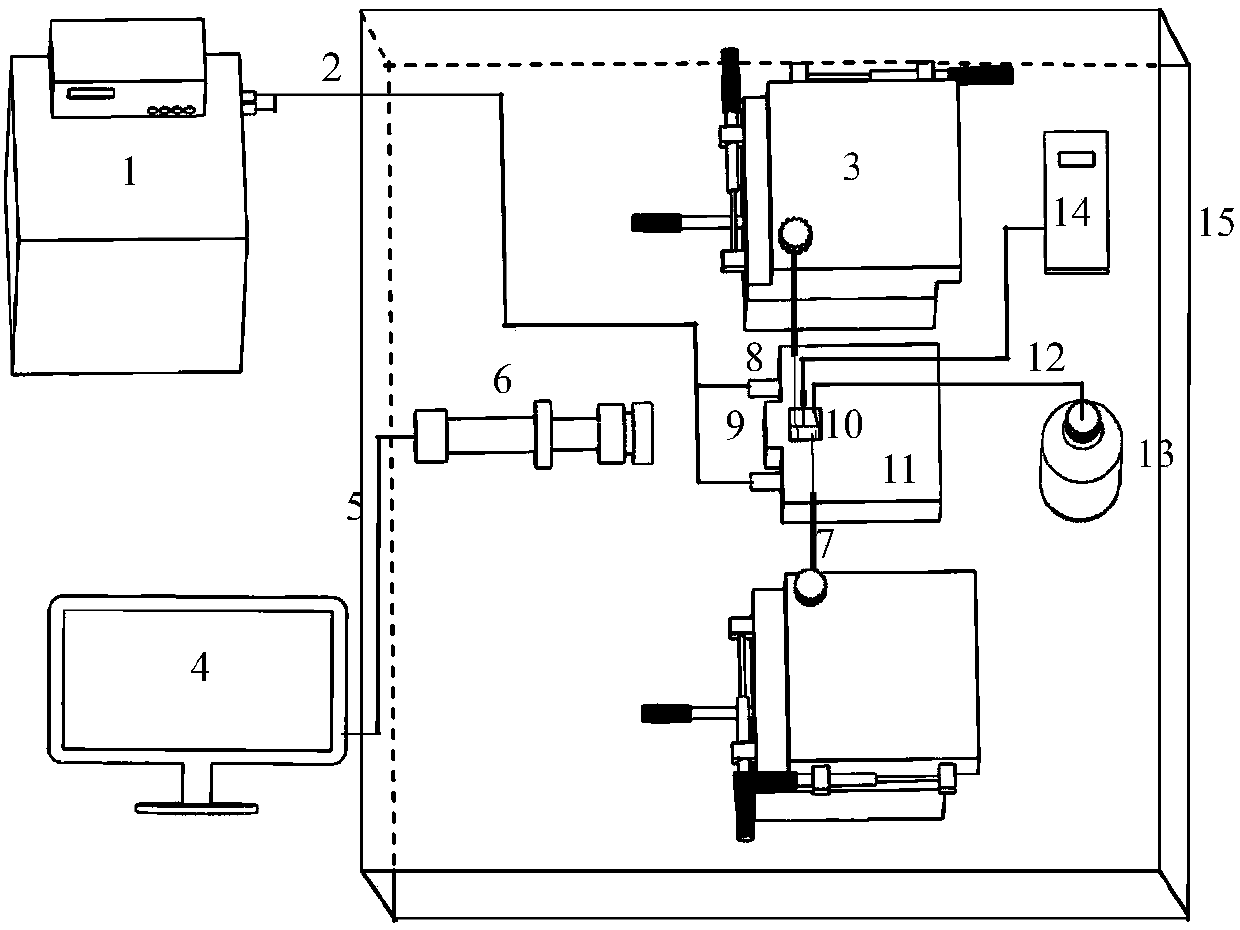

[0072] A device for measuring the microscopic adhesion between hydrate particles in a gas phase system, such as figure 1 As shown, it includes a first microscopic operating system, a second microscopic operating system, a visual reaction device, a camera / video system, a low temperature constant temperature control system, and a temperature acquisition instrument;

[0073] The first microcosmic operating system includes a high-precision first three-dimensional manipulation platform 3 and a first operating arm 7 clamped on the first three-dimensional manipulation platform 3, and the first three-dimensional manipulation platform 3 includes a first XY manipulation platform 17 (model LY-125 -LM-50), the first Z operating platform 18 (model LZ125-2), the contact surfaces of the two are fixed by bolt connection;

[0074] The second microscopic operating system includes a high-precision second three-dimensional manipulation platform and a second operating arm clamped on the second thr...

Embodiment 2

[0078] According to a device for measuring the microscopic adhesion force between hydrate particles in the gas phase system described in Example 1, the difference is that

[0079] The visualized reaction device includes a temperature-controlled circulation tank 11, a circulation fluid inlet 8, a circulation fluid outlet, an operating unit 10, and a double-glazed window 9. The low-temperature constant temperature control system is respectively connected to the temperature-controlled circulation tank 11 through the circulation fluid inlet 8 and the circulation fluid outlet. An operating unit 10 is arranged in the temperature-controlled circulation tank 11, and a double-glazed window 9 is arranged on the side of the operating unit 10 corresponding to the position of the photographing / video recording system.

[0080] The low-temperature constant temperature tank 1 is respectively connected to the circulating fluid inlet 8 and the circulating fluid outlet through the rubber pipeline...

Embodiment 3

[0096] The device described in embodiment 2 measures the method for the microcosmic adhesion between hydrate particles in the gas phase system, such as Figure 4 shown, including the following steps:

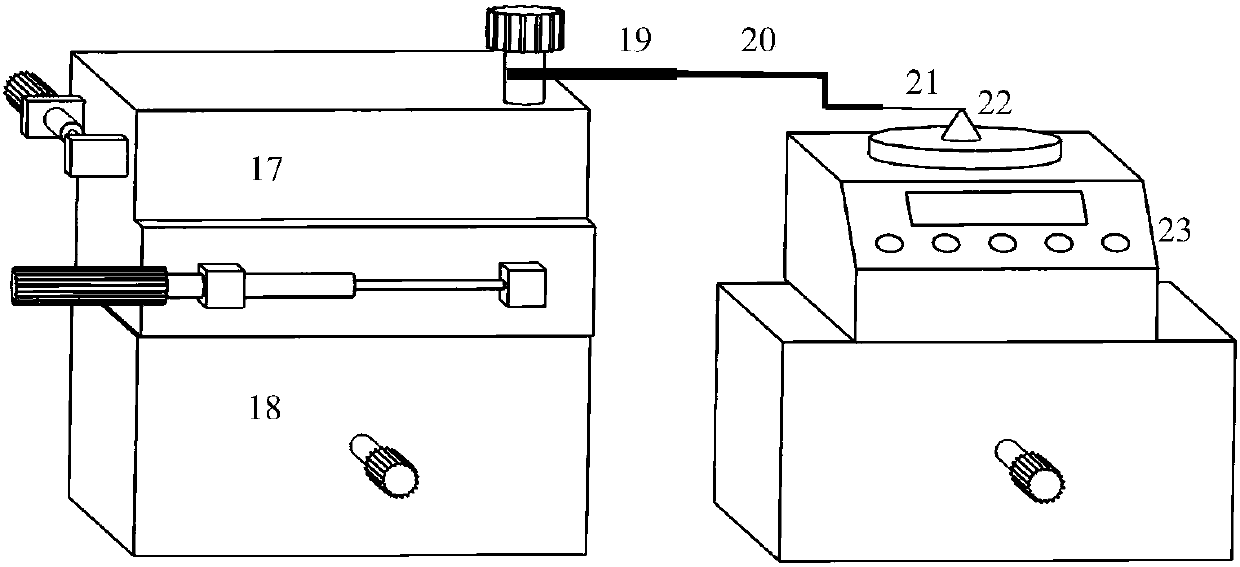

[0097] A. Determine the elastic coefficient of glass fiber

[0098] a, the first operating arm 7 is clamped on the first three-dimensional control platform 3, the small cone 22 is placed on the stage of the precision electronic balance 23, the precision electronic balance 23 is opened, and the reading m of the precision electronic balance 23 is recorded 1 ;

[0099] b. Operate the first three-dimensional control platform 3 so that the end of the first glass fiber 21 is in contact with the apex of the small cone 22 on the precision electronic balance 23 stage;

[0100] c. Operate the first Z operating platform 18 to slowly lower the first operating arm 7 by 300-500um, and read the descending displacement Δx through the joystick of the first Z operating platform 18 1 , and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com