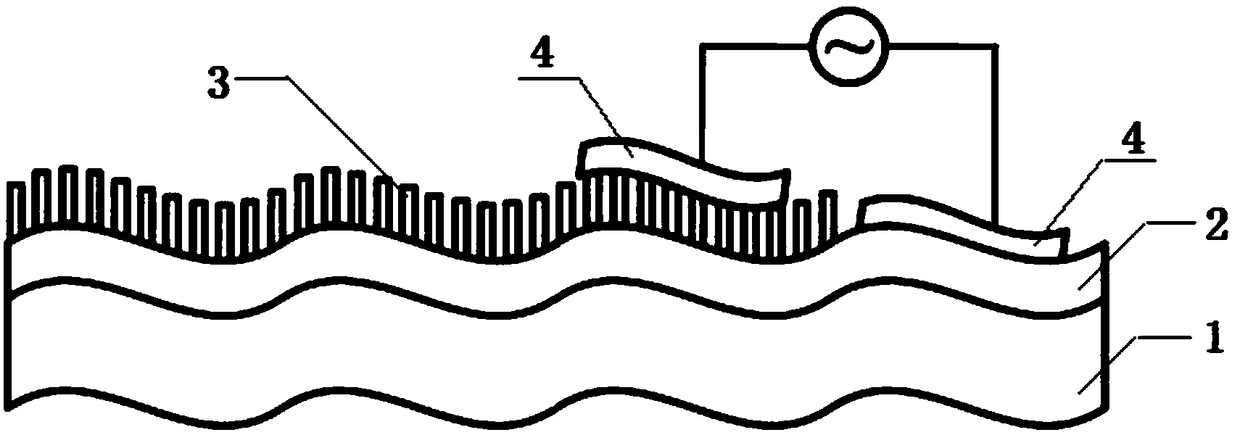

Flexible gas-sensitive sensor based on tin oxide/gallium oxide heterojunction nano array and manufacturing method of flexible gas-sensitive sensor

A gas sensor and nano-array technology, applied in the field of gas sensing, can solve problems such as being unable to withstand high temperatures, and achieve the effects of accelerated response, stable performance, and reduced operating temperature and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

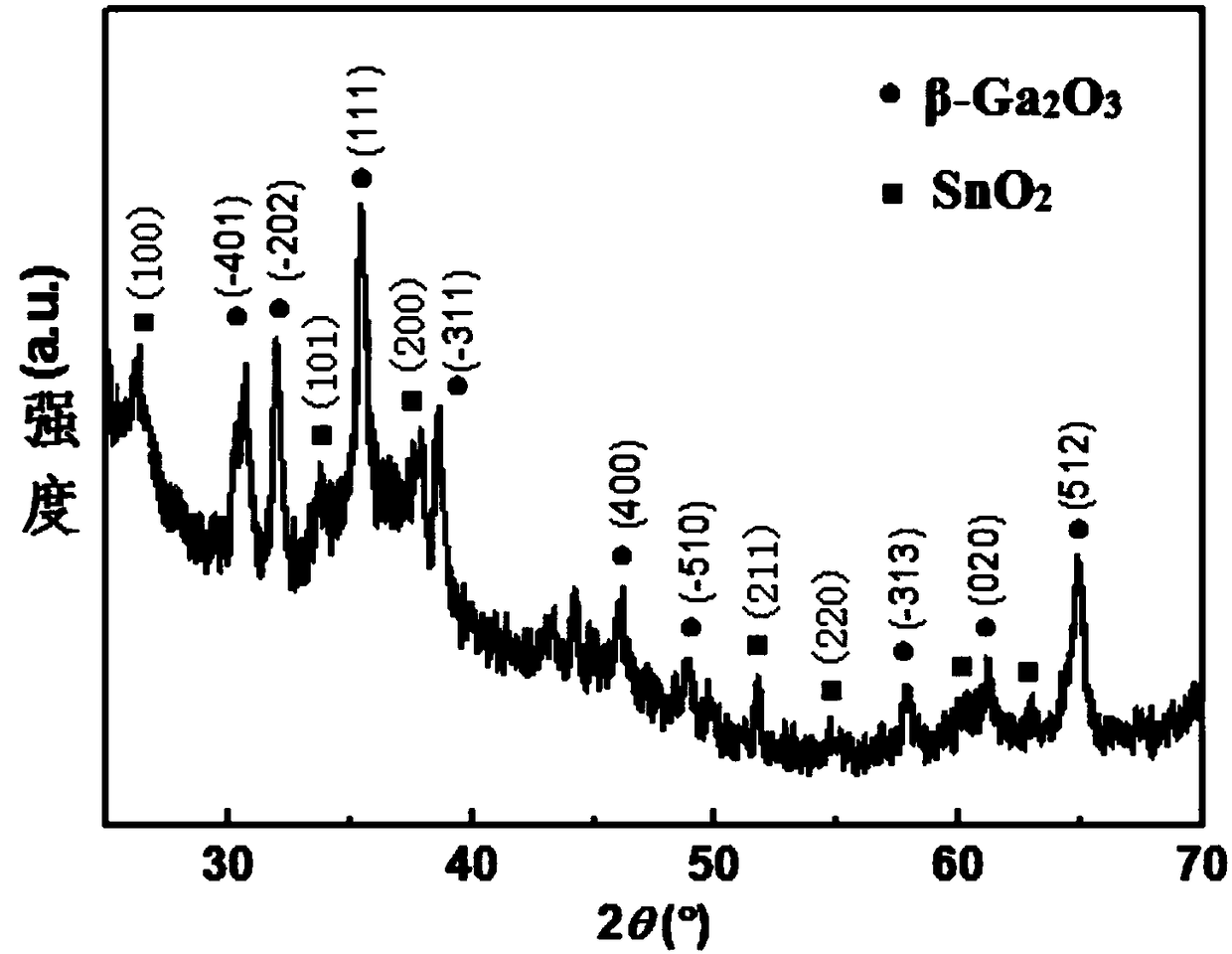

[0036] Based on SnO 2 / β-Ga 2 o 3 A method for preparing a flexible gas sensor of a heterojunction nanoarray, comprising the following steps:

[0037] (1) Clean the glass fiber cloth substrate. The cleaning process is as follows: soak the substrate in acetone, ethanol, and deionized water for 10 minutes, then rinse it with deionized water after taking it out, and finally wash it with dry N 2 Blow dry and set aside;

[0038] (2) SnO 2 The target is placed on the target stage of the magnetron sputtering deposition system, and the glass fiber cloth substrate processed in step (1) is fixed on the sample holder and put into the vacuum chamber;

[0039] (3) Vacuum the cavity, adjust the pressure in the vacuum cavity, pass in argon, heat the glass fiber cloth substrate, and deposit a layer of SnO by magnetron sputtering 2 thin film, followed by in-situ annealing, where, SnO 2 The distance between the target and the glass fiber cloth substrate was set at 5 cm, and the chamber pr...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is that in step (3), a layer of SnO is deposited by magnetron sputtering 2 The sputtering power of the film is 90W, and the in-situ annealing temperature is 550°C; in step (4), the gallium metal is heated to 85°C to form liquid gallium metal. Others are identical with embodiment 1, specifically as follows:

[0050] Based on SnO 2 / β-Ga 2 o 3 A method for preparing a flexible gas sensor of a heterojunction nanoarray, comprising the following steps:

[0051] (1) Clean the glass fiber cloth substrate. The cleaning process is as follows: soak the substrate in acetone, ethanol, and deionized water for 10 minutes, then rinse it with deionized water after taking it out, and finally wash it with dry N 2 Blow dry and set aside;

[0052] (2) SnO 2 The target is placed on the target stage of the magnetron sputtering deposition system, and the glass fiber cloth substrate processed in step (1) is fixed on the sample holde...

Embodiment 3

[0060] The difference between this embodiment and Embodiment 1 is that in step (3), the cavity pressure is 1.5 Pa when the glass fiber cloth substrate is heated, and a layer of SnO is deposited by magnetron sputtering. 2 The sputtering power of the film is 90W; in step (4), the gallium metal is heated to 85°C to form liquid gallium metal, and the annealing temperature is 750°C. Others are identical with embodiment 1, specifically as follows:

[0061] Based on SnO 2 / β-Ga 2 o 3 A method for preparing a flexible gas sensor of a heterojunction nanoarray, comprising the following steps:

[0062] (1) Clean the glass fiber cloth substrate. The cleaning process is as follows: soak the substrate in acetone, ethanol, and deionized water for 10 minutes, then rinse it with deionized water after taking it out, and finally wash it with dry N 2 Blow dry and set aside;

[0063] (2) SnO 2 The target is placed on the target stage of the magnetron sputtering deposition system, and the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com