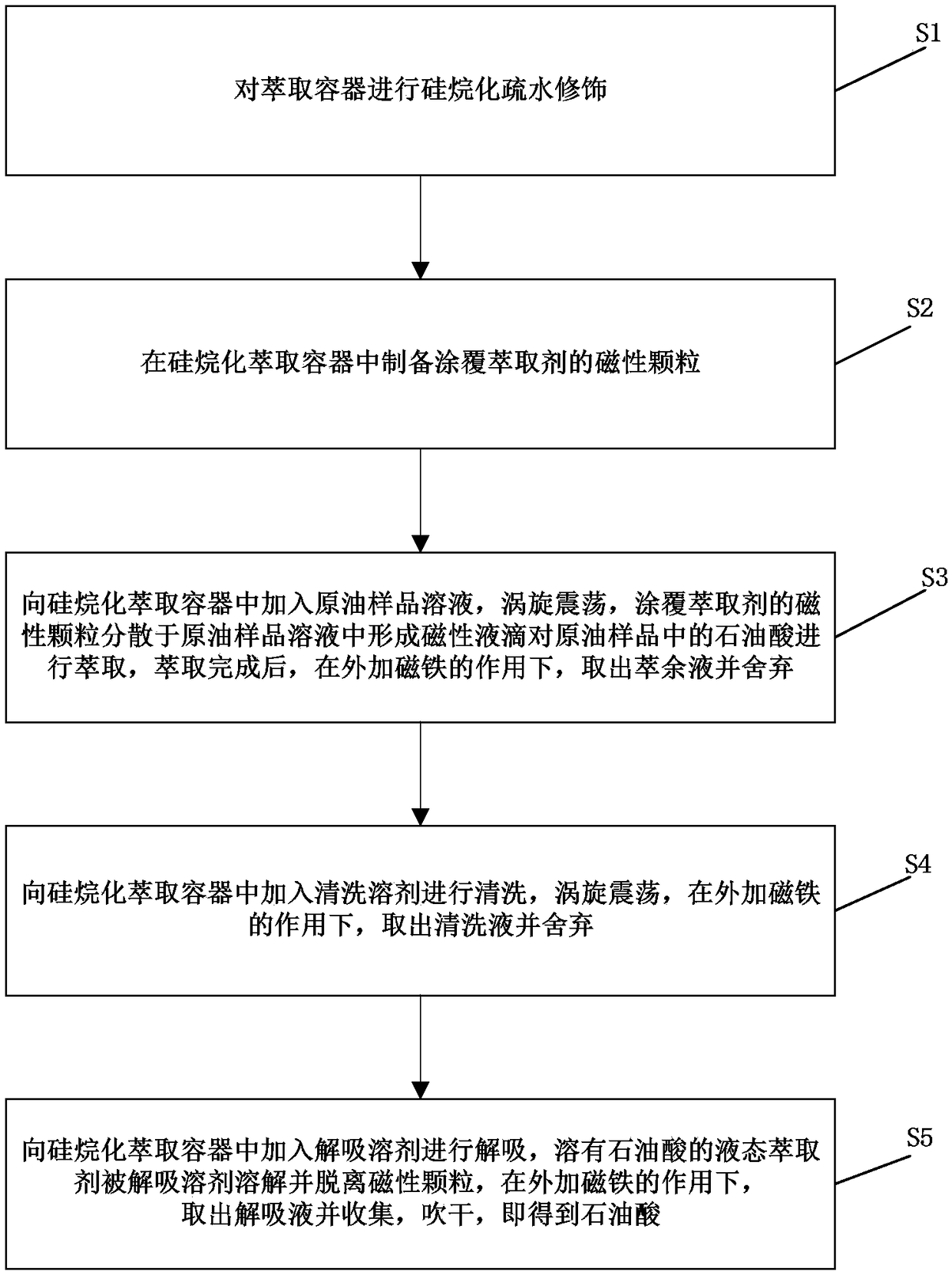

Magnetic liquid drop dispersion and extraction method for separating petroleum acid

A magnetic droplet and petroleum acid technology, applied in separation methods, liquid solution solvent extraction, material separation, etc., can solve problems such as poor reproducibility of liquid-liquid extraction, difficult preparation of adsorbents, cumbersome and time-consuming operations, etc., to achieve improved The effect of recovery and sensitivity, high practical value, and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

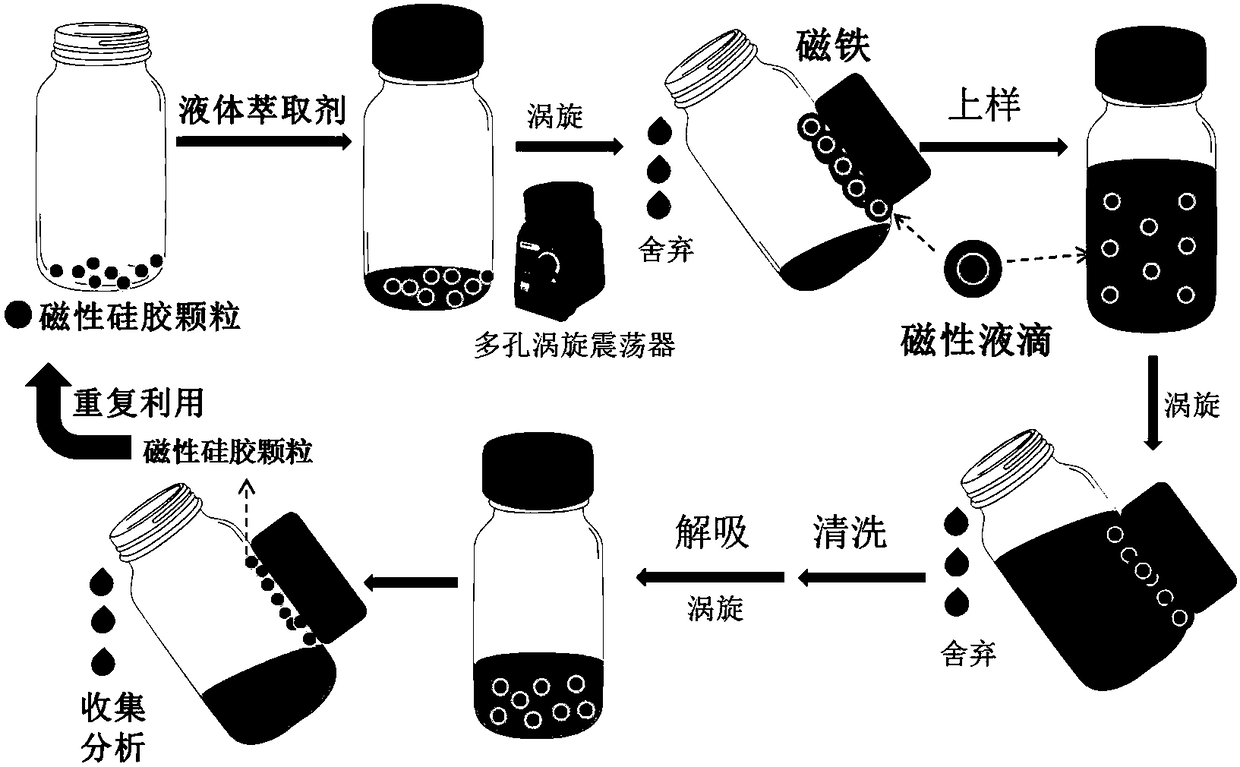

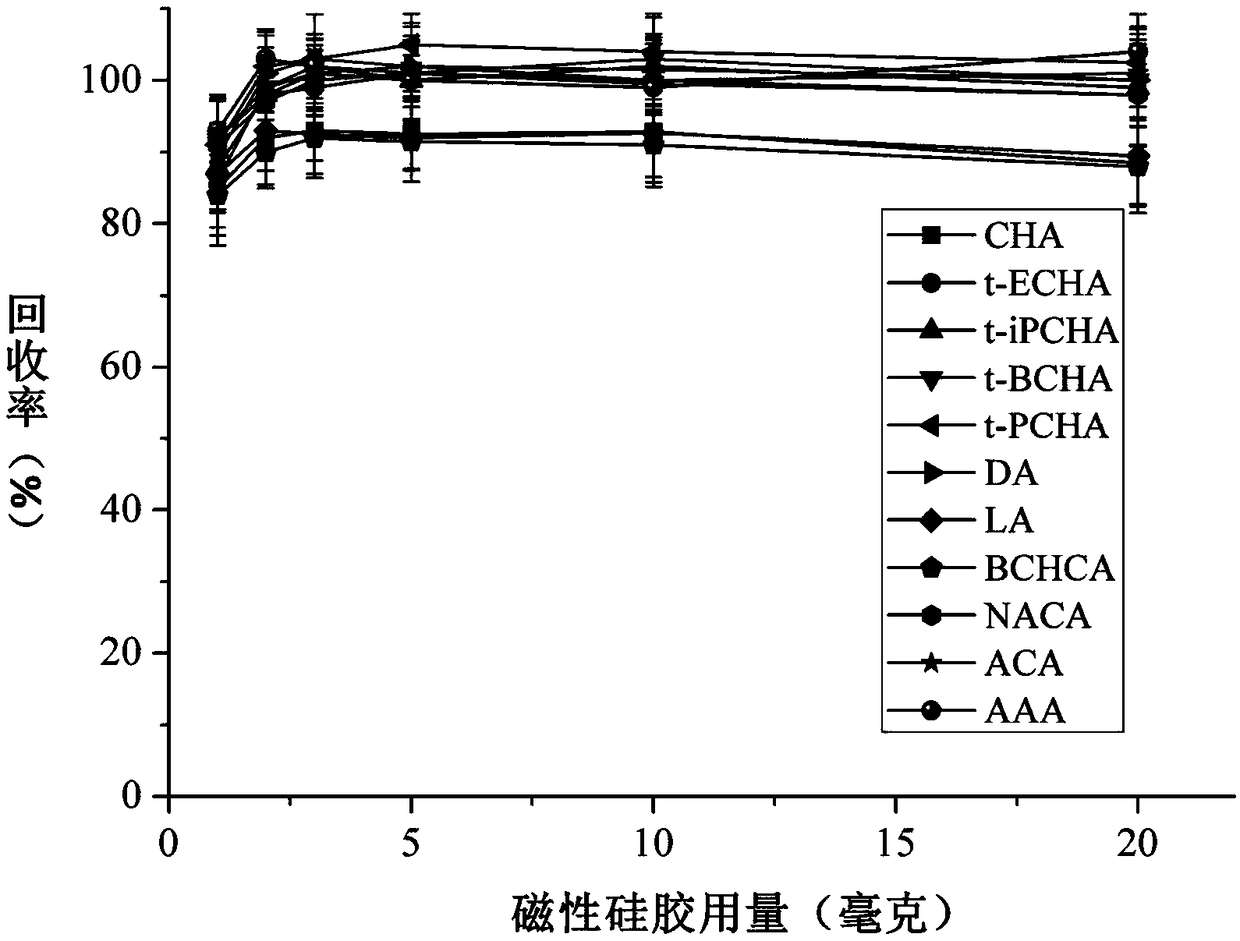

Embodiment 1

[0039]Soak a 2mL glass sample bottle in n-hexane solution containing 5% dichlorodimethylsilane, take it out after standing for 8 hours, wash it with methanol and n-hexane, and dry it in an oven at 60°C , to obtain a silanized glass sample bottle; weigh 5 mg of magnetic nano-silica gel particles and place them in a silanized glass sample bottle, add 0.1 mL of 10 wt % ammonia water, vortex and mix them, and put Under the action, use a pipette to take out the excess ammonia water free from the magnetic nano silica gel particles to obtain the magnetic nano silica gel particles coated with ammonia water; add 1mL containing 0.1 The n-hexane sample solution of g / mL crude oil was vortexed for 2 minutes. At this time, the magnetic nano-silica gel particles coated with ammonia water were dispersed in the sample in the form of magnetic droplets. After the extraction, the raffinate was taken out under the action of a square magnet. Add 1 mL of n-hexane to the silanized glass sample bottle...

Embodiment 2

[0041] The difference between this embodiment and embodiment 1 is only that: the glass sample bottle of 5mL is soaked in the n-hexane solution containing 8% dichlorodimethylsilane, the consumption of magnetic nano-silica gel particles is 2mg, and the concentration of ammonia water is 15wt%, the addition of crude oil sample solution is 2mL, the dilution factor of crude oil sample is 6 times, the addition of acetone is 0.3mL; the rest is basically the same as embodiment 1.

Embodiment 3

[0043] The difference between this embodiment and embodiment 1 is only that a glass sample bottle with a specification of 10 mL is soaked in a n-hexane solution containing 9% dichlorodimethylsilane, the amount of magnetic nano-silica gel particles is 10 mg, and the concentration of ammonia water is 18wt%, the addition of crude oil sample solution is 4mL, the dilution factor of crude oil sample is 10 times, the addition of acetone is 0.4mL; the rest is basically the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com