Core-shell structure NCM (nickel manganese cobalt) ternary cathode material containing carbon nanotube and preparation method thereof

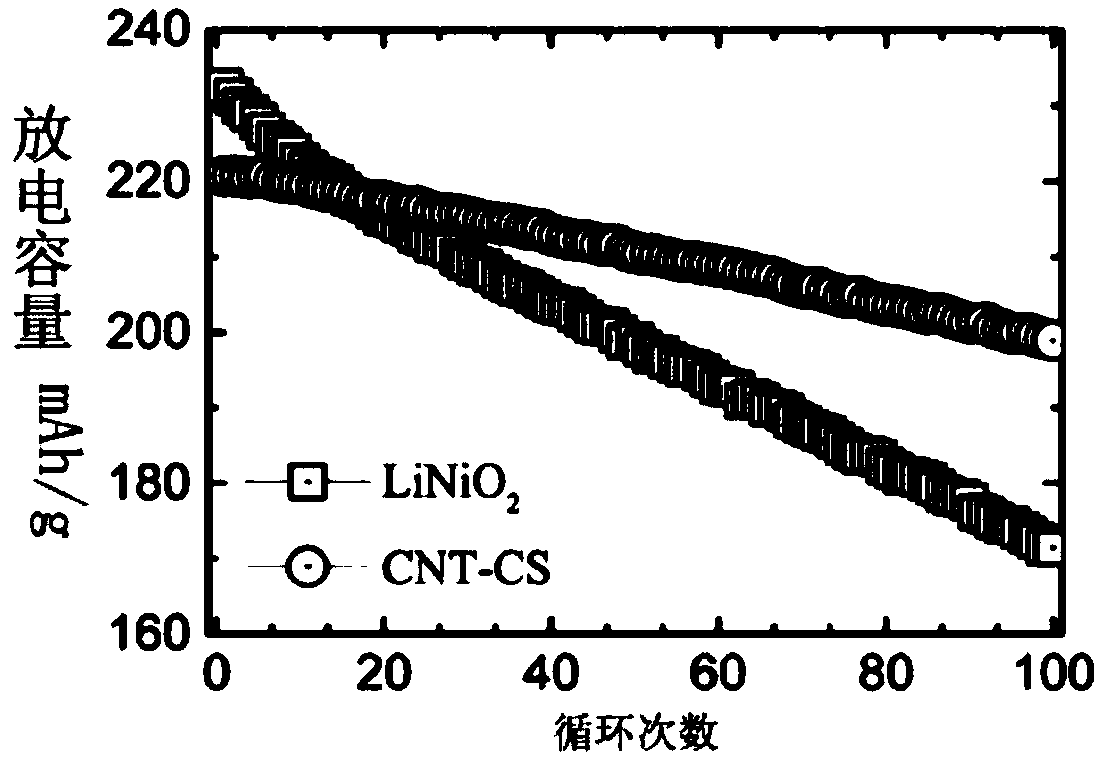

A technology of positive electrode material and core-shell structure, which is applied in the field of core-shell structure NCM ternary positive electrode material containing carbon nanotubes and its preparation, can solve the problems of unsuitability and extremely poor capacity retention of electric vehicles, and achieve high capacity, Increased rate capability and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of the core-shell structure NCM ternary cathode material comprising carbon nanotubes of the present invention mainly comprises the following steps:

[0055] (1) Use a solvent to dissolve a certain stoichiometric amount of nickel compounds, and mix them uniformly to form a nickel compound solution. Mix the nickel compound with the complexing agent and the precipitating agent solution, and use the co-precipitation reaction to prepare the core precursor material solution of the core-shell structure NCM ternary cathode material;

[0056] (2) In the presence of a complexing agent and / or a precipitating agent, add nickel compounds, cobalt compounds, The mixed solution of manganese compound is subjected to co-precipitation reaction to obtain nickel-cobalt manganese compound with core-shell structure;

[0057] (3) After mixing the nickel-cobalt-manganese compound containing the core-shell structure and the lithiated compound prepared in the step (2), roa...

Embodiment 1

[0077] First, the Ni(NO 3 ) 2 ·6H 2 O aqueous solution is continuously pumped into a certain amount of deionized water, NaOH (aqueous solution) and NH 4 OH (aqueous) reaction vessel. At the same time, NaOH (4.0M, aqueous solution) (the molar ratio of sodium hydroxide to transition metal is 2.0) and a sufficient amount of NH 4 OH (aqueous solution) (the molar ratio of ammonia water to transition metal ions is 1.2) is pumped into the reaction vessel as a chelating agent. During the synthesis process, high-speed stirring was used to make the initially formed Ni(OH) 2 The particles are spherical.

[0078] In order to form the core-shell structure, the corresponding shell structure component [Ni 0.8 co 0.1 mn 0.1 ](OH) 2 Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O aqueous solution and Mn(NO 3 ) 2 The solution (the molar ratio Ni:Co:Mn=8:1:1) is pumped into the reaction vessel at a certain rate, and the pH value in the vessel is maintained, and the stirring rate is con...

Embodiment 2

[0085] First, the Ni(NO 3 ) 2 ·6H 2 O aqueous solution is continuously pumped into a certain amount of deionized water, NaOH (aqueous solution) and NH 4 OH (aqueous solution) reaction vessel. At the same time, NaOH (4.0M, aqueous solution) (the molar ratio of sodium hydroxide to transition metal is 1.8) and a sufficient amount of NH 4 OH (aqueous solution) (the molar ratio of ammonia water to transition metal ions is 1.5) is pumped into the reaction vessel as a chelating agent. During the synthesis process, high-speed stirring was used to make the initially formed Ni(OH) 2 The particles are spherical.

[0086] In order to form the core-shell structure, the corresponding shell structure component [Ni 0.5 co 0.2 mn 0.3 ](OH) 2 Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O aqueous solution and Mn(NO 3 ) 2 The solution (molar ratio Ni:Co:Mn=5:2:3) is pumped into the reaction vessel at a certain rate, and the pH value and stirring rate in the vessel are kept constant. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com