Flat wire continuous wave staggered winding and stator comprising same

A technology of wave winding and flat wire, which is applied in the field of flat wire continuous wave winding dislocation winding and stators containing flat wire continuous wave winding dislocation winding, can solve problems such as easy failure, high manufacturing cost, and complicated motor circuit design, and achieve Improve product quality, reduce noise, reduce the effect of the second harmonic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

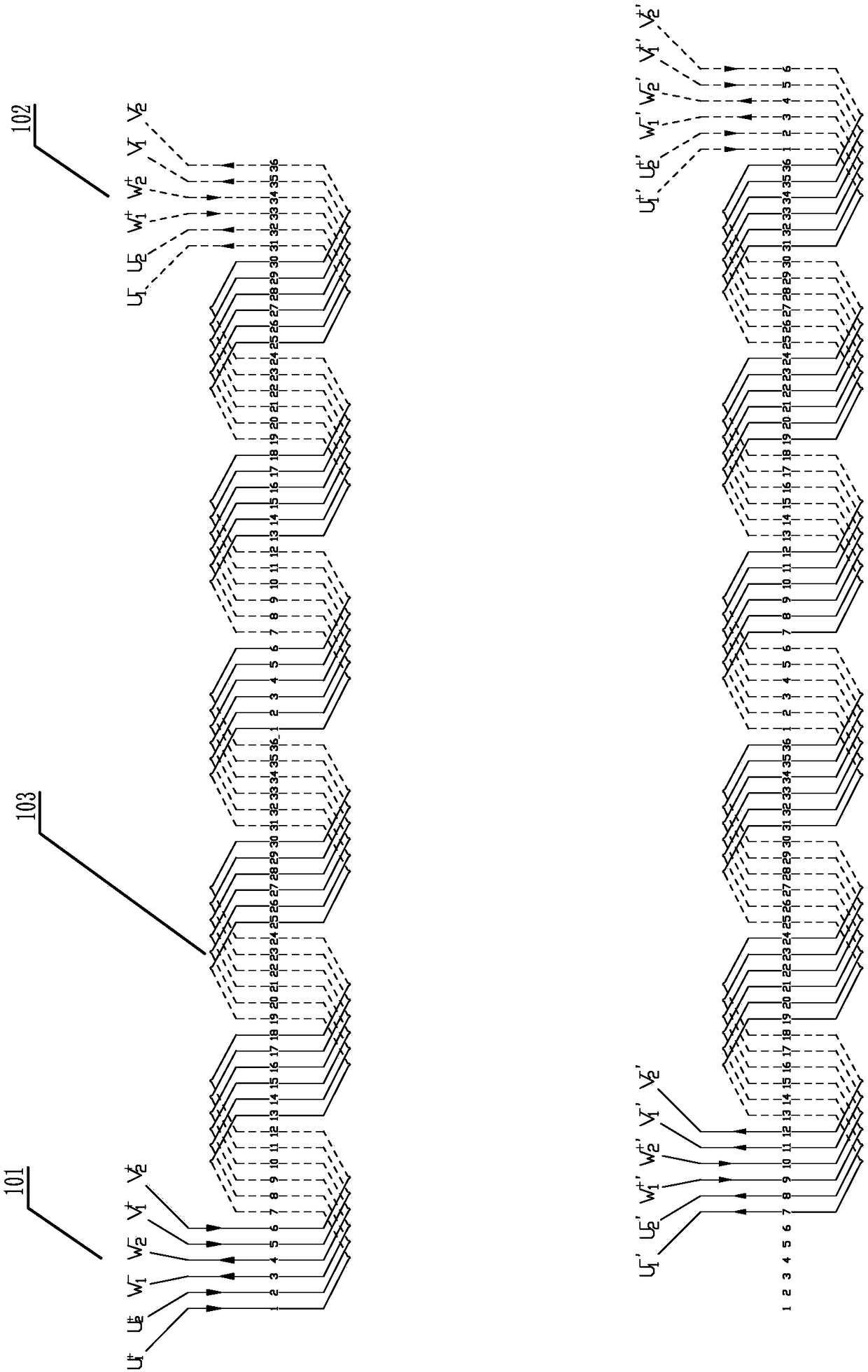

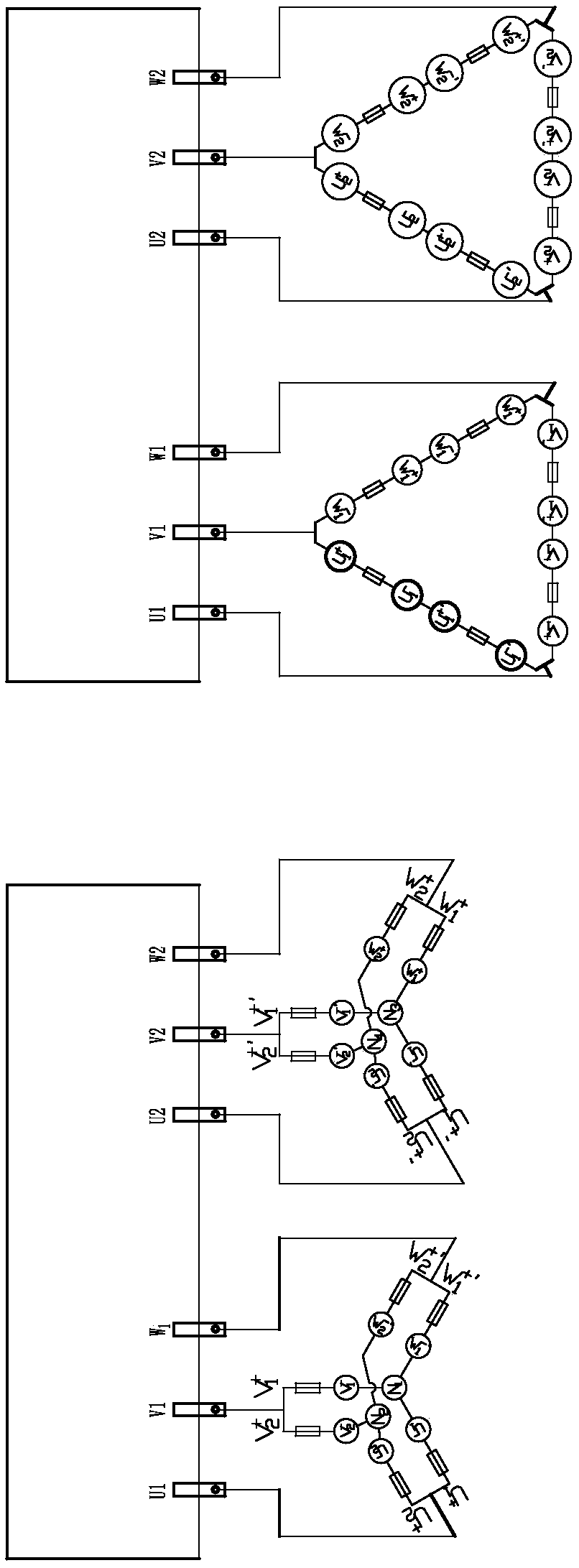

[0079] Example 1: Take a motor with two slots per pole and one phase as an example, such as Figure 4 , Figure 5 The dislocation winding of a continuous wave of a flat wire is shown, which consists of an incoming wire part 101, an outgoing wire part 102, and an S-shaped winding between the incoming wire part 101 and the outgoing wire part 102. The S-shaped wavy line 103 is composed of an S-shaped wavy line 103 including an effective side portion 301 for placing in the stator slot body 503, a straight line portion 302 located outside the two sides of the slot body 503, and an end portion 303 connecting adjacent straight line portions 302; In the S-shaped corrugated wire 103, a dislocation winding part 104 is provided, and the position of the dislocation winding part 104 is arranged in a dislocation arrangement between the conductors in each phase conductor, and the dislocation winding part 104 is arranged in the middle of the entire waveform wire Position, according to the nu...

Embodiment 2

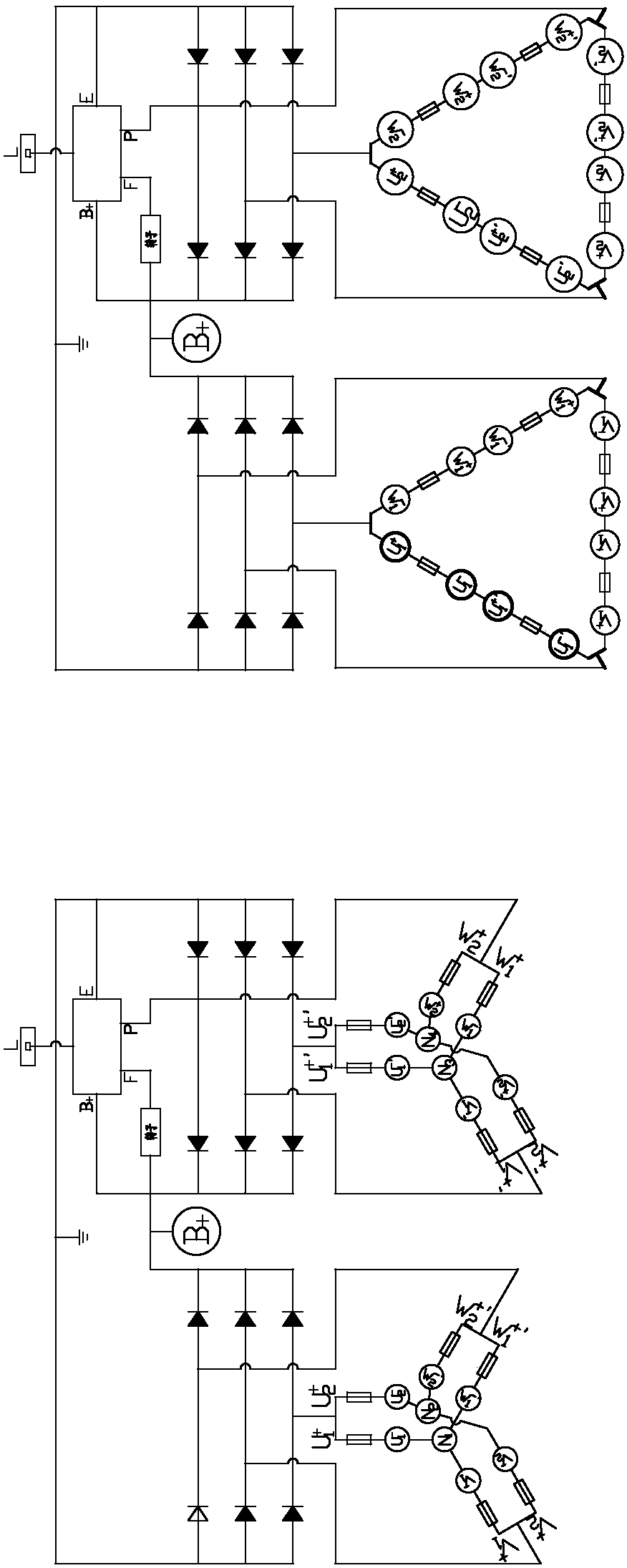

[0086] Embodiment 2: Take a motor with two slots per pole and one phase as an example, such as Figure 9 The flat wire continuous wave wound dislocation winding shown has the same basic structure as that of Embodiment 1. In the S-shaped wave wire 103, a dislocation winding part 104 is provided, but for the dislocation winding part 104, according to each pole and each phase For the number of distributed slots q, one misplaced winding part 104 is provided in the co-directional wave winding formed by the three phases U, V, and W every other wave winding. Taking the 36-slot motor as an example, in the S-shaped waveform line 103, five co-directional wave windings with the ends 303 above the effective side portion 301 are included, namely, the first wave winding, the second wave winding, the third wave winding, and the first wave winding. For the four-wave winding and the fifth-wave winding, the first-wave winding, the third-wave winding, and the fifth-wave winding are respectively ...

Embodiment 3

[0088] Embodiment 3: Take a motor with 3 slots per pole and each phase as an example, such as Figure 10 , Figure 11 Shown is a flat wire continuous wave winding with a dislocation winding, and other structures are the same as in Embodiment 1. In the S-shaped corrugated wire 103, a dislocation winding part 104 is provided, and the wires in each phase wire of the dislocation winding part 104 are mutually The position between them is set as a misplaced arrangement. The misplaced winding part 104 is set in the middle of the entire waveform line. According to the number of slots q distributed in each pole and phase is 3, for the U, V, W three-phase winding composed of three-phase windings in the entire waveform The wave winding in the S-shaped waveform line 103 in the middle of the line, in the U-phase line, U 1 line pitch y 1 for: y 1 =q×m+(q-1)=3×3+(3-1)=11, U 2 line pitch y 2 for: y 2 = q× m-1= 3×3-1=8, U 3 line pitch y 3 for: y 3 = q× m-1= 3×3-1=8; in the V phase li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com