PMSM (permanent-magnet synchronous motor) control system based on super-twisted SMC (sliding mode control) algorithm and work method of PMSM control system

A permanent magnet synchronous motor and control system technology, which is applied in the control system, motor control, vector control system, etc., can solve the problems of power factor reduction, leakage inductance and voltage drop increase, and the limitation of motor speed regulation range, etc., to eliminate Effects of chattering and increased approach speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

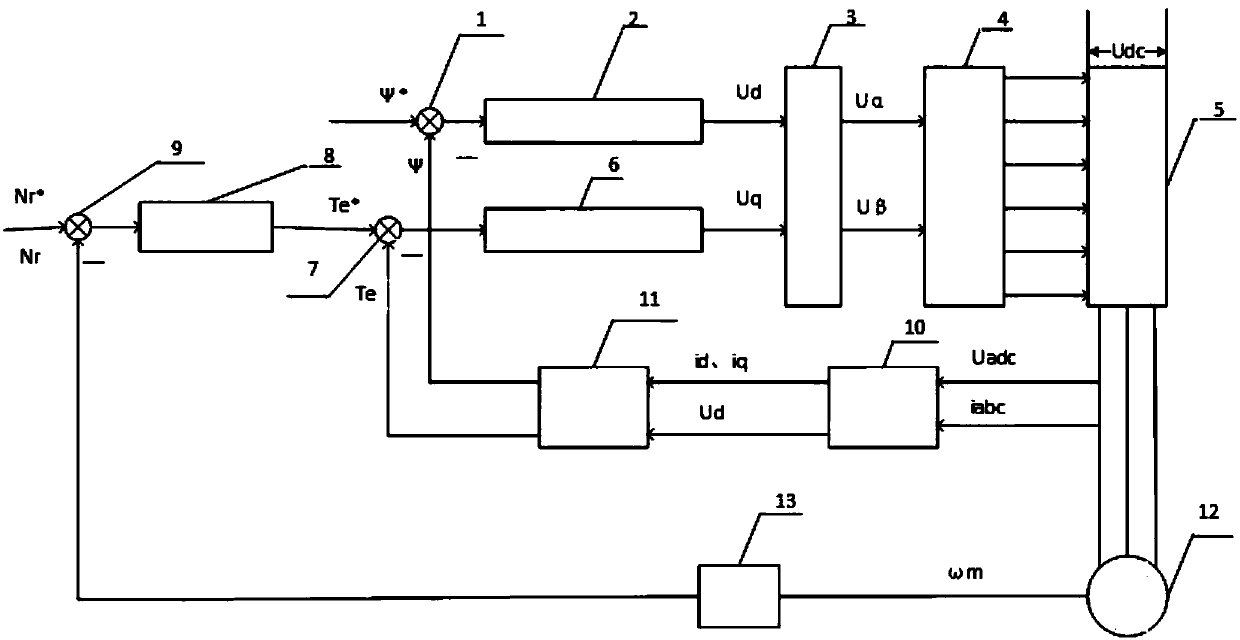

[0089] A permanent magnet synchronous motor control system based on super twisted synchronous film variable structure algorithm, such as figure 2 As shown, it includes a first comparison unit 1, a first super twisted slide film control module 2, a park inverse transformation module 3, a SVPWM module 4, an inverter module 5, a second super twisted slide film control module 6, and a second comparison unit 7. Speed regulator 8, third comparison unit 9, 3 / 2 conversion module 10, flux linkage torque estimation unit 11, permanent magnet synchronous motor module 12, speed calculation unit 13;

[0090] The permanent magnet synchronous motor module 12, the speed calculation unit 13, the third comparison unit 9, the speed regulator 8, and the second comparison unit 7 are sequentially connected, the inverter module 5, the 3 / 2 conversion module 10, and the flux linkage torque estimation unit 11 are connected sequentially, and the flux linkage torque estimation unit 11 is respectively con...

Embodiment 2

[0097] The working method of the permanent magnet synchronous motor control system based on the super-twisted synchronous film variable structure algorithm described in embodiment 1 includes:

[0098] (1) Calculate the rotational speed N of the permanent magnet synchronous motor module 12 by the speed calculation unit 13 r , the calculation formula is shown in formula (I):

[0099]

[0100] In formula (I), ω m refers to the mechanical angle of the permanent magnet synchronous motor module 12;

[0101] (2) Proportional-integral controller is used in the speed control outer loop module, and the given speed is obtained through the third comparison unit 9 and the rotational speed N obtained in step (1) r The difference, the difference is input to the speed regulator 8;

[0102] (3) Obtained by the speed regulator 8 is the torque comparison data obtained by the speed regulator 8; K p is the proportional coefficient, K i is the integral coefficient;

[0103] Get feedb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com