Junction-bar gallium nitride-based high-electron-mobility transistor

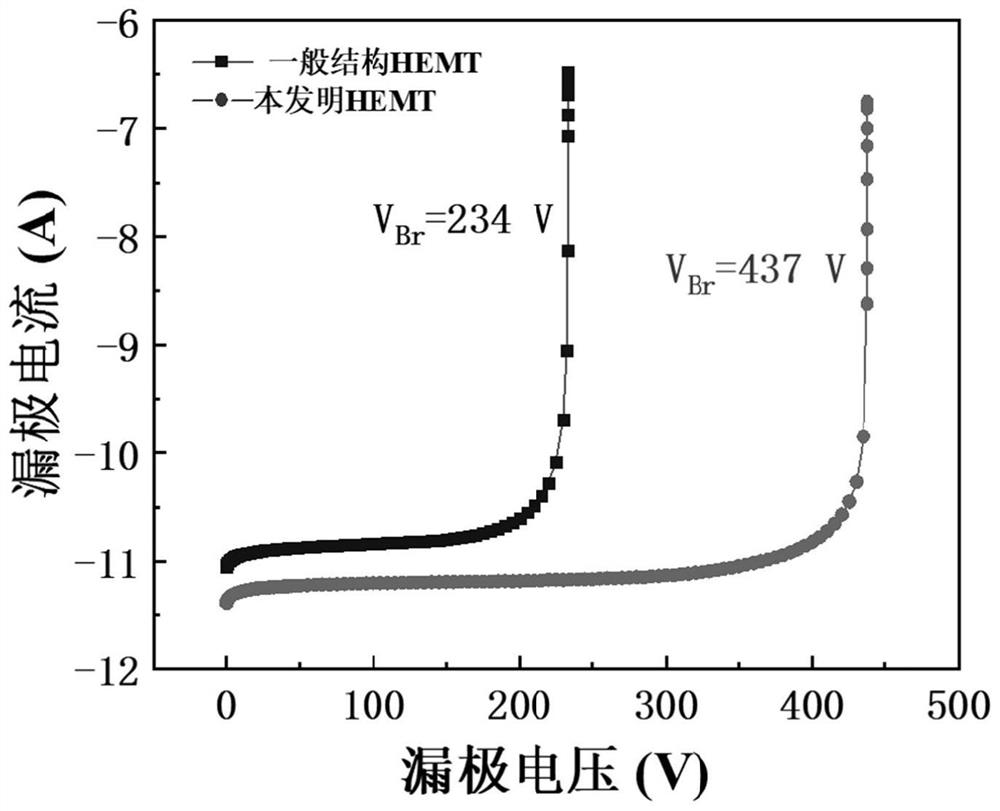

A high electron mobility, gallium nitride based technology, applied in the field of junction strip gallium nitride based high electron mobility transistors, can solve the problem of insufficient withstand voltage capability, inability to exert device leakage current, and increase reverse withstand voltage gate Leakage current and other problems, to ensure the frequency characteristics and switching characteristics, avoid Miller capacitance effect, and improve the effect of breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

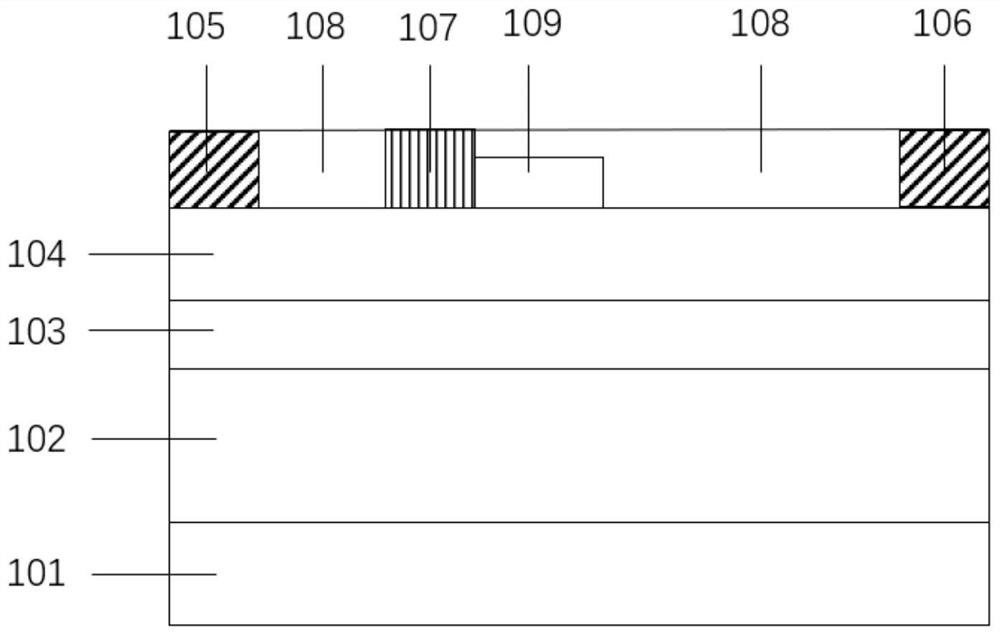

[0037] This embodiment provides a junction stripe GaN-based high electron mobility transistor, the schematic diagram of which is as follows: figure 1As shown, its structure includes a substrate 101, a buffer layer 102, a GaN channel layer 103, an AlGaN barrier layer 104, a source electrode 105, a gate electrode 106, a drain electrode 107, a passivation layer 108, and a P-type doped AlGaN strip 109 ; The substrate 101, the buffer layer 102, the GaN channel layer 103, and the AlGaN barrier layer 104 are stacked sequentially from bottom to top; the source electrode 105, the gate electrode 106, and the drain electrode 107 are respectively arranged on the AlGaN barrier The upper surface of the layer 104; the source electrode 105 and the drain electrode 107 both form ohmic contact with the upper surface of the AlGaN barrier layer 104, and the gate 106 and the upper surface of the AlGaN barrier layer 104 form a Schottky contact contact; the P-type doped AlGaN strips 109 are located o...

Embodiment 2

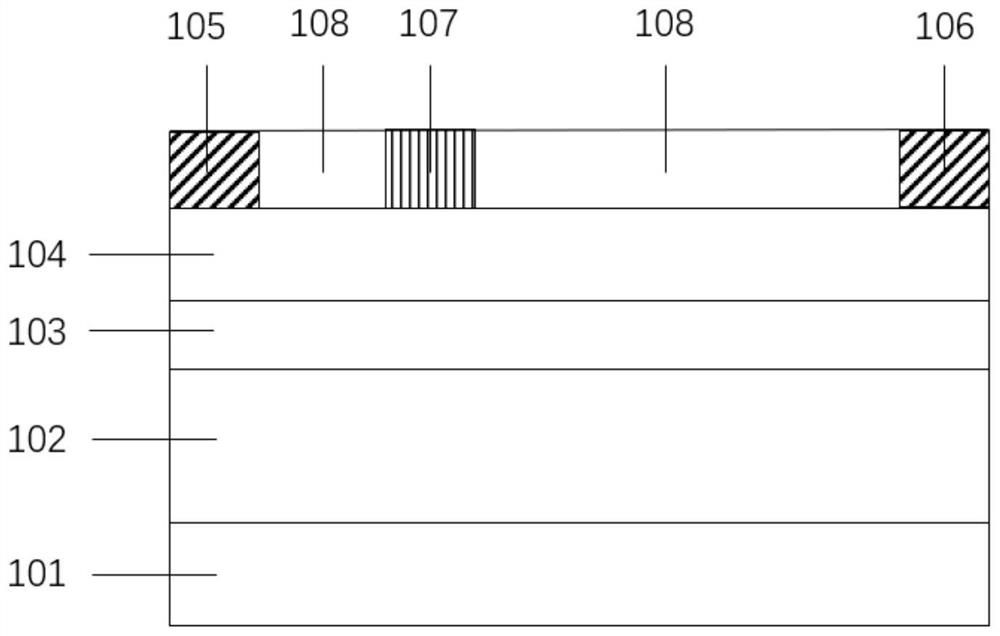

[0048] like Figure 5 As shown, this embodiment provides a junction stripe GaN-based high electron mobility transistor, the difference from Embodiment 1 is the unintentional doping of P-type doped AlGaN strips 109 between the gate 106 and the drain 107 Three PN junction strips are grown on the upper surface of the hetero AlGaN barrier layer 104, and the three P-type doped AlGaN strips 109 and the unintentionally doped AlGaN barrier layer 104 form multiple PN junction strips, and the total length of the multiple junction strips is The distance between the gate 106 and the drain 107 is not exceeded.

Embodiment 3

[0050] like Image 6 As shown, this embodiment provides a junction stripe GaN-based high electron mobility transistor. The difference from Embodiment 1 is that the P-type doped AlGaN stripe 109 is partially embedded between the gate 106 and the drain 107. In the doped AlGaN barrier layer 104, the depth of the unintentionally doped AlGaN barrier layer 104 between the gate 106 and the drain 107 embedded by the P-type doped AlGaN strips 109 is smaller than that of the P type doped AlGaN strip 109 height.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com