Constant temperature self-heating device containing phase change microcapsules

A phase-change microcapsule and self-heating technology, which is applied in the directions of heating appliances for therapeutic treatment, microcapsule preparations, cooling appliances for therapeutic treatment, etc. and other problems, to achieve the effect of stable performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

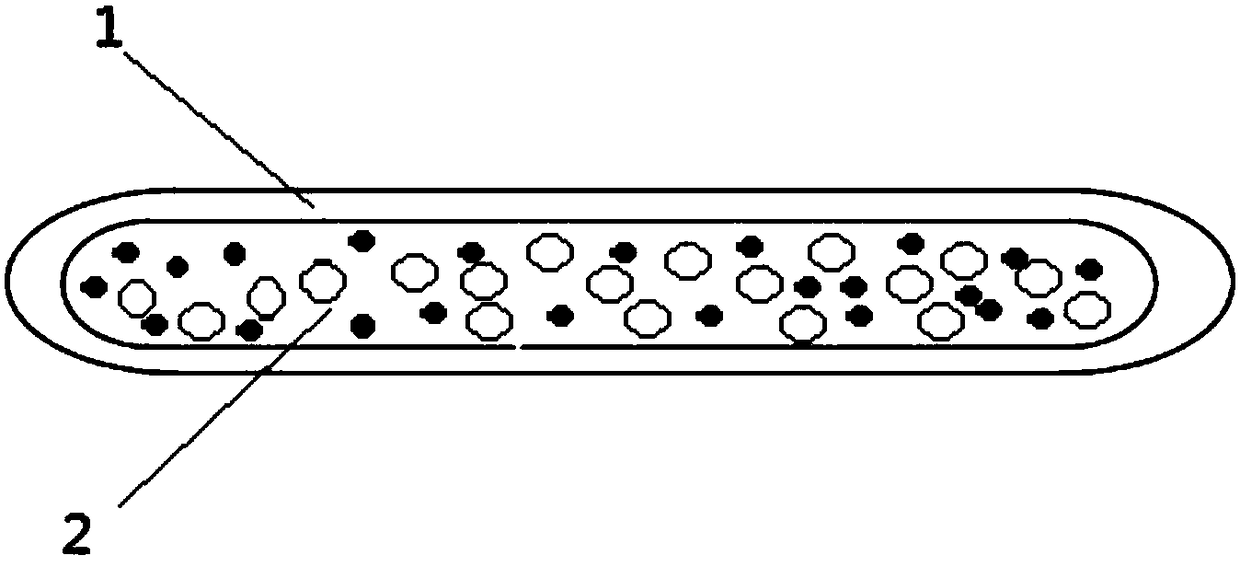

[0047] see figure 1 , the constant temperature self-heating appliance containing phase change microcapsules, comprising a gas-permeable holding bag 1 and a constant temperature heating composition 2 placed in the holding bag 1;

[0048] Example 1

[0049] Preparation of phase change microcapsules:

[0050] (1) Mix formaldehyde, melamine and water with a weight concentration of 37%, adjust the pH of the system to 8 with triethanolamine, and stir and react for 30 minutes at 65°C to obtain an aqueous prepolymer solution;

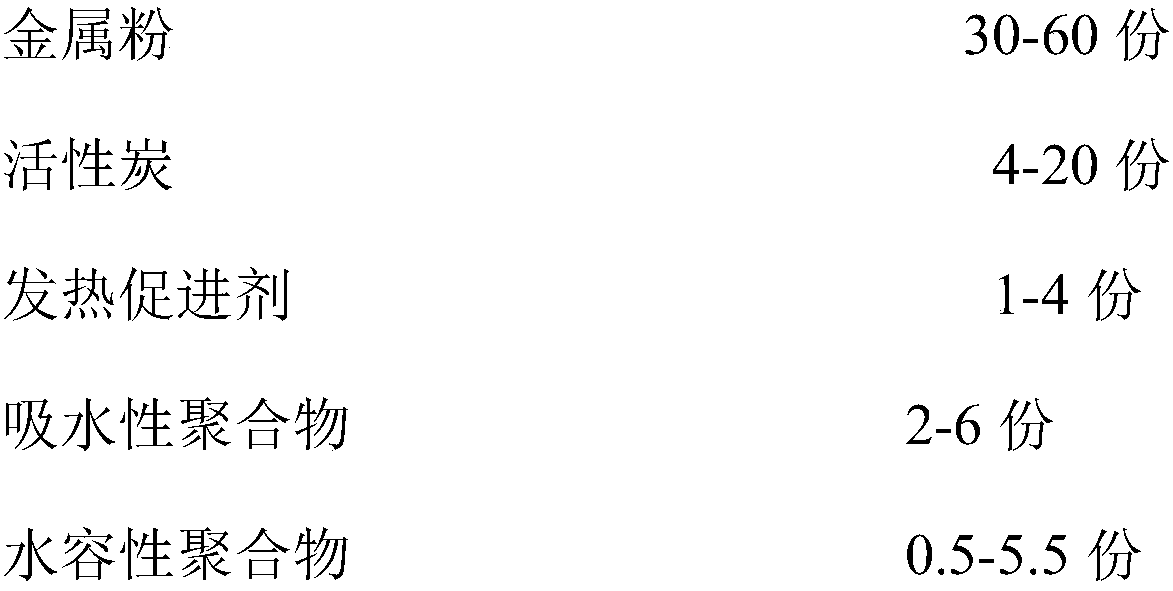

[0051] The dosage ratio of each component is:

[0052] 37% formaldehyde: melamine=2: 1, molar ratio;

[0053] The weight consumption of water is 8 times of melamine;

[0054](2) Adding paraffin wax and water with a melting point of 45°C to the prepolymer of step (1), the weight consumption of water is 5 times that of melamine, at 30°C, the speed of 1600r / min is stirred and emulsified for 40min, and the temperature is adjusted to 55°C, the stirring speed is...

Embodiment 2

[0065] Preparation of phase change microcapsules:

[0066] (1) Mix formaldehyde, melamine and water with a weight concentration of 37%, adjust the pH of the system to 7 with triethanolamine, and stir and react for 20 minutes at 70°C to obtain an aqueous prepolymer solution;

[0067] The dosage ratio of each component is:

[0068] 37% formaldehyde: melamine=2: 1, molar ratio;

[0069] The weight consumption of water is 10 times of melamine;

[0070] (2) Adding paraffin wax and water with a melting point of 43°C to the prepolymer of step (1), the weight consumption of water is 3 times that of melamine, at 25°C, the speed of 2000r / min is stirred and emulsified for 20min, and the temperature is adjusted to 65°C, the stirring speed is 1000r / min, add sulfuric acid with a weight concentration of 1% dropwise, adjust the drop rate, so that the pH of the system drops to 3 within 1 hour, stop the dropwise addition, raise the temperature to 72°C, add water, the water Add 3 times the we...

Embodiment 3

[0082] The detection method and results of phase change paraffin microcapsules resistance to boiling water are as follows:

[0083] At room temperature, the phase-change microcapsules of 100g embodiment 1 are put into 4 identical heaters A, B, C and D respectively in equal amounts, and in each container, the weight of the phase-change microcapsules is 25g, Adding equal weight concentration respectively in the heater is each 100g of 10% sodium chloride aqueous solution, stirs evenly, the container of the phase-change microcapsule that melamine-formaldehyde resin is housed is heated, and 4 identical heaters are heated respectively to 40°C, 60°C, 80°C and 100°C for half an hour, filtered, dried, and weighed. The results are shown in Table 1.

[0084] Table 1

[0085] Heater model

[0086] As can be seen from Table 1, the quality of the phase-change microcapsules after heating is slightly reduced, because the phase-change microcapsule sample of detection contains unwrap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com