Cleaning flour and preparation method thereof

A technology of flour and cleansing, which is applied in the field of daily chemical products, can solve the problems of inability to improve skin condition, strong irritation, poor cleaning ability, etc., and achieve the effect of reducing skin sensitivity, alleviating irritation, and good self-protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of cleansing flour raw materials:

[0043] Preparation of sapinberry extract:

[0044] Grind the dried Sapindus fruit into Sapindus powder, add the Sapindus powder into the ethanol solution with a mass fraction of 60%, stir for 2 hours at 50°C under airtight conditions, filter after standing for 20 minutes, and take the filtrate in Drying under a vacuum condition of 85° C., to obtain the sapindus fruit extract.

[0045] Preparation of papaya extract:

[0046] Put fresh papaya slices in a vacuum drying oven, dry at 62°C for 24 hours, crush the papaya slices to obtain papaya powder, mix them with 75% ethanol by mass fraction, ultrasonically treat for 32 minutes at room temperature, and let stand After 30min, filter to obtain the first filter residue and the first filtrate; get the first filter residue and mix it with distilled water, ultrasonically treat it for 30min at room temperature, and after standing for 28min, filter again to obtain the second filter ...

Embodiment 2~6

[0053] The operation steps of Examples 2-6 are the same as those in Example 1, wherein the components and their amounts are shown in Table 1-3.

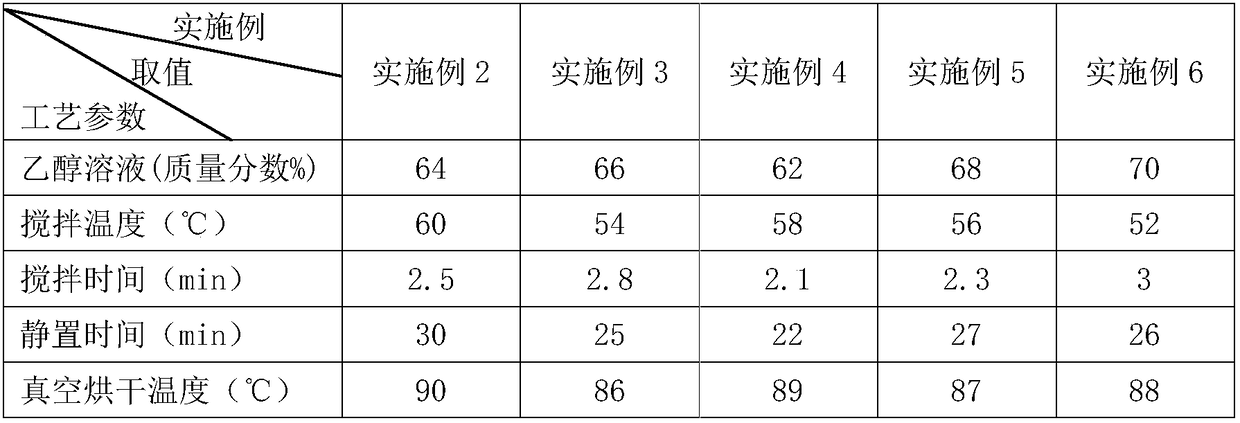

[0054] Components and consumption in the preparation method of table 1 sapinsia sapinsia fruit extract

[0055]

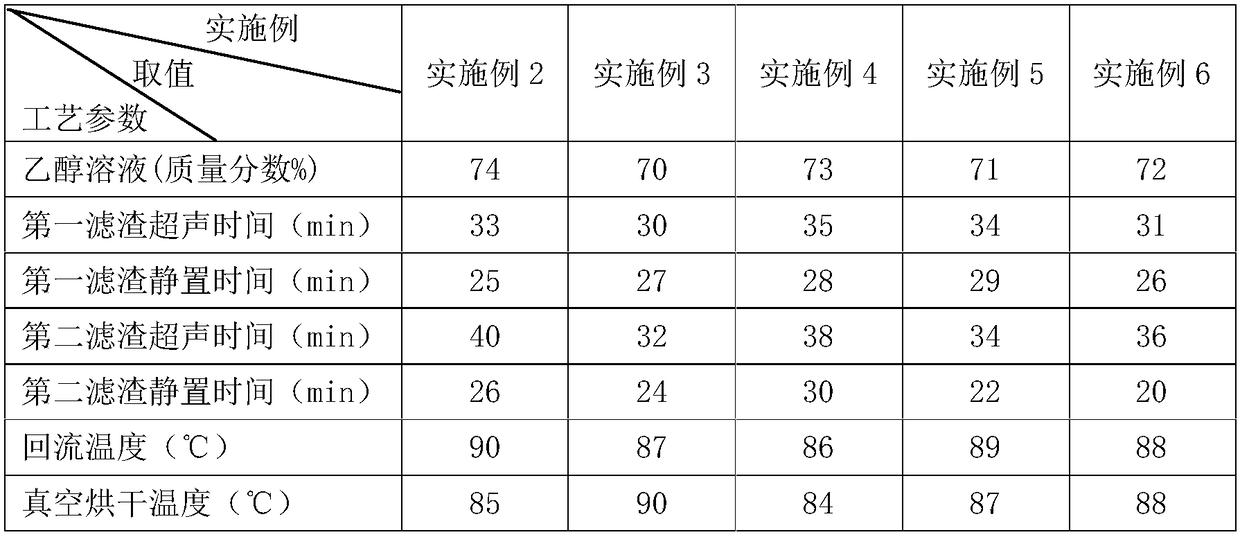

[0056] Composition and consumption in the preparation method of table 2 papaya extract

[0057]

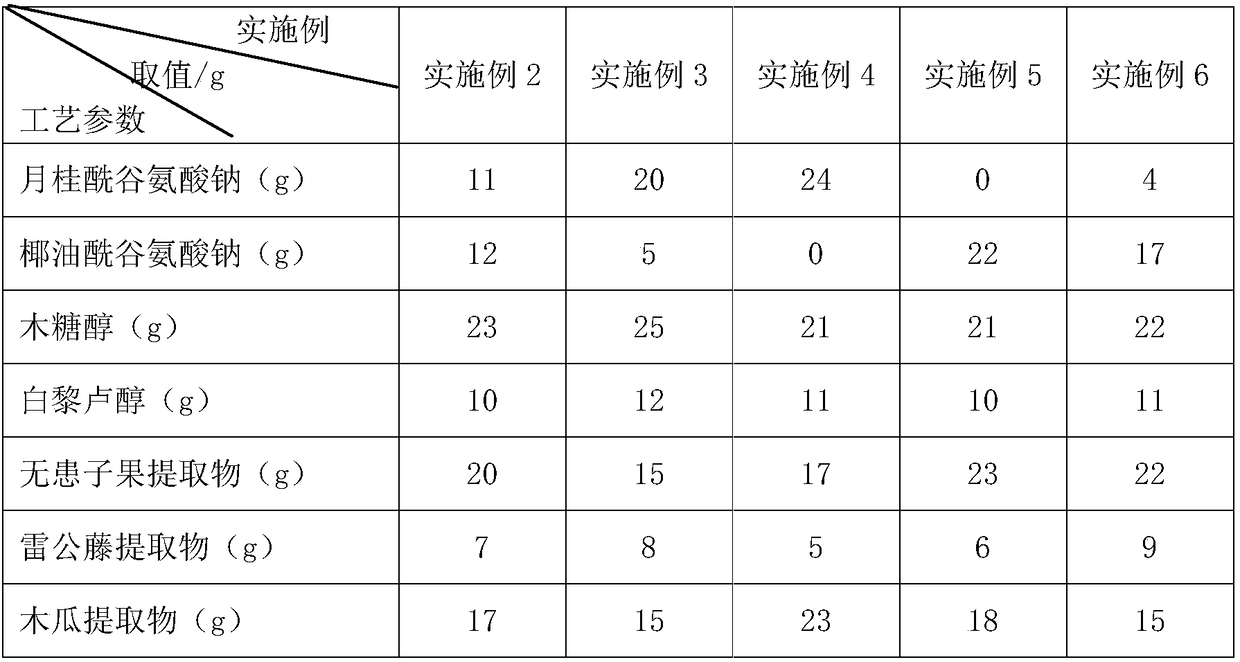

[0058] Components and consumption in the preparation method of table 3 cleansing flour

[0059]

Embodiment 7-12

[0061] Sapinberry extract is prepared as follows:

[0062] Grind the dried Sapindus fruit into Sapindus powder, add the Sapindus powder into the ethanol solution with a mass fraction of 60%, stir for 2 hours at 50°C under airtight conditions, filter after standing for 20 minutes, and take the filtrate in Drying under a vacuum condition of 85° C., to obtain the sapindus fruit extract.

[0063] Papaya extract is prepared as follows:

[0064] Put fresh papaya slices in a vacuum drying oven, dry at 62°C for 24 hours, crush the papaya slices to obtain papaya powder, mix them with 75% ethanol by mass fraction, ultrasonically treat for 32 minutes at room temperature, and let stand After 30min, filter to obtain the first filter residue and the first filtrate; get the first filter residue and mix it with distilled water, ultrasonically treat it for 30min at room temperature, and after standing for 28min, filter again to obtain the second filter residue and the second filtrate; the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com