Welding method loading cold source and displacement-controlled load in welding

A technology of displacement control and welding method, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., and can solve the problems of unreachable effect, unsatisfactory local heat treatment effect of large structural parts, reheat cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

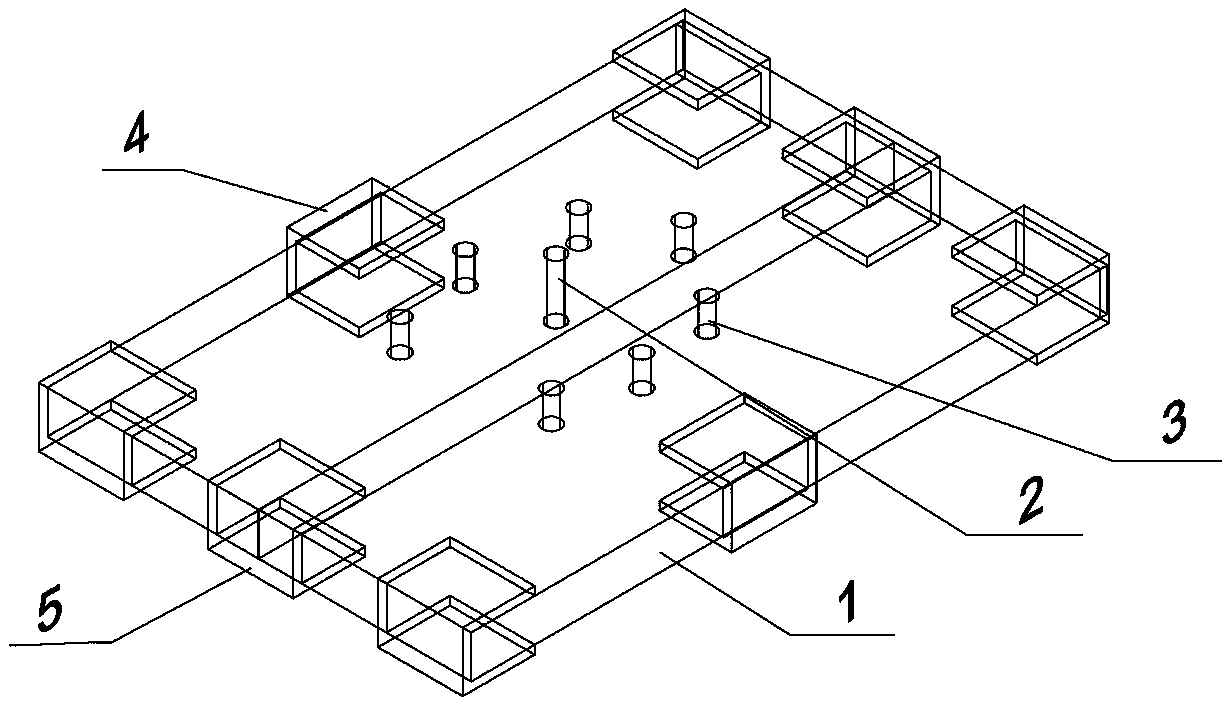

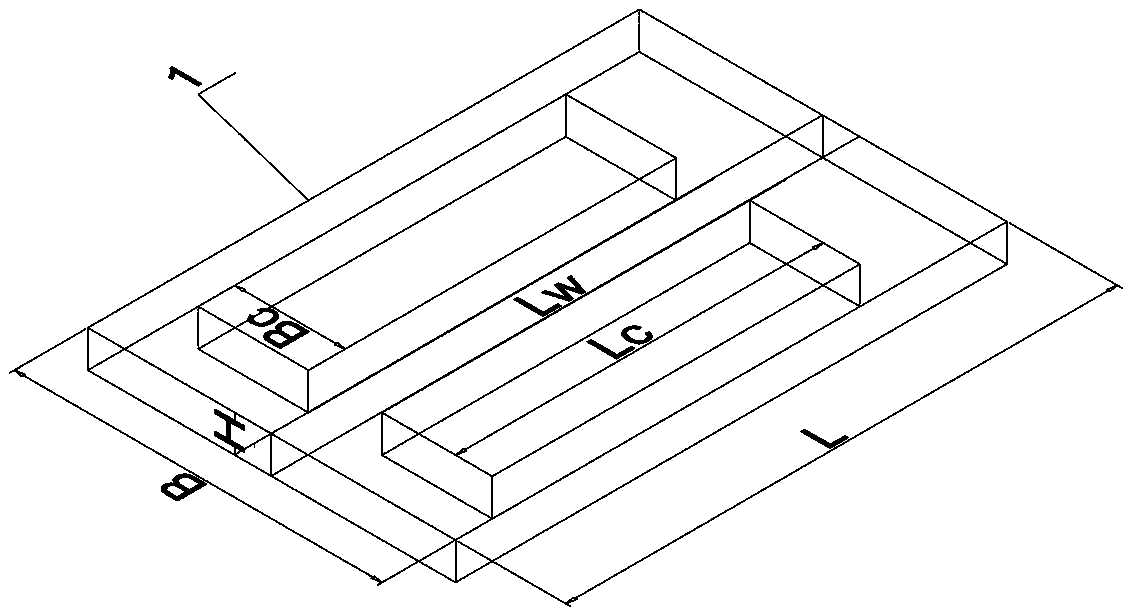

[0017] Such as figure 1 , figure 2 The length L=0.2m, the width B=0.15m, the thickness H=0.004m, the length L of the welding seam shown in the weldment 1 w =0.2m, the length of the range of cold source L c =0.2m, width B c =0.04m, welding speed v w =0.003m / s, welding current I=180A, welding voltage U=27V, the maximum allowable temperature drop of the steel plate within the scope of the cold source is ΔT c =20℃, cold source power is P _ =1000w. Steel specific heat capacity c=460J / (kg℃), density ρ=7850kg / m 3 , Expansion coefficient α=1.2E-5 / ℃, steel plate surface convective heat transfer coefficient h=10W / (m 2 ℃).

[0018] The inventive method comprises the following concrete steps:

[0019] 1. Calculation of relevant parameters: the displacement growth rate of the tensile load perpendicular to the weld is The displacement growth rate of the tensile load parallel to the weld is The unloading time of mechanical tensile displacement load is about The displacement u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com