Preparation method of organic silicon self-repairing antifouling material

A self-healing, silicone technology, used in antifouling/underwater coatings, biocide-containing paints, coatings, etc. The effect of pollution period effect, shortening use period effect and broad application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The process of preparing the silicone self-repairing antifouling material according to the present embodiment is:

[0019] (1) 1.0 g of melamine and mass percentage concentration of 25% were added to the three flask, and magnetically stirred at 20 ° C for 1 h;

[0020] The amino content of melamine is 2.4 × 10 -2 Mol, the mass of glutaraldehyde is 9.8 g, the aldehyde group in the pentaroxaldehyde solution is 4.8 × 10 -2MOL, the molar ratio of the amino functional group and the aldehyde group function group is 0.5;

[0021] (2) PDMS and 20 ml of tetrahydrofuran were added to the three flasks of step (1) at a PDMS and 20 ml of tetrahydrofuran of a 24.0 g of a molecular weight of 1000 g / mol;

[0022] (3) At a water bath condition at 25 ° C, the three flask of the magnetic stirring step (2) for 3 h, resulting in the silicone self-repairing antifouling material.

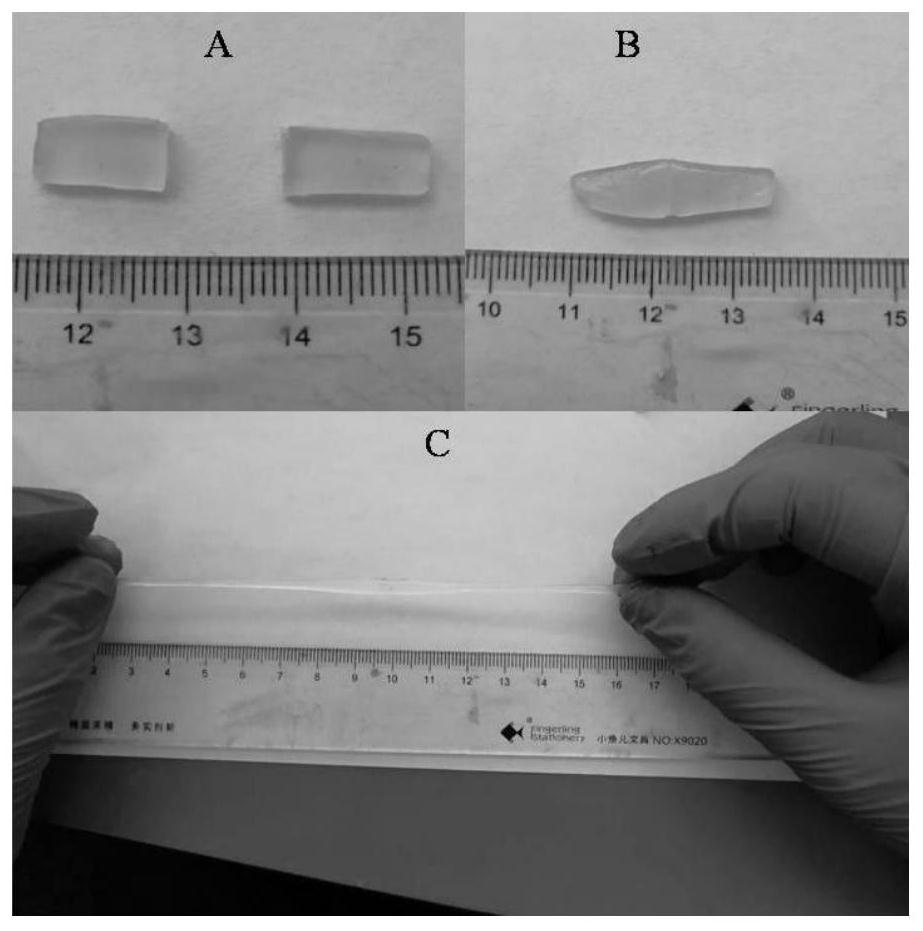

[0023] The process of self-repairing the self-repairing material of the silicone prepared in the present embodimen...

Embodiment 2

[0025] The process of preparing the silicone self-repairing antifouling material according to the present embodiment is:

[0026] (1) 1.26 g of melamine and mass percentage concentration of 25% were added to the three flask, and magnetic force was stirred at 25 ° C for 1 h;

[0027] The amino content of 3.0 × 10 in melamine is 3.0 × 10 -2 Mol, the mass of the glutaraldehyde is 16.3 g, the aldehyde group in the aqueous solution of glutaraldehyde is 8.0 × 10 -2 MOL, the molar ratio of the amino functional group and the aldehyde functional group is 0.375;

[0028] (2) PDMS and 20 ml of tetrahydrofuran were added 80 ml of tetrahydrofuran in the step (1) of PDMS and 20 mL of tetrahydrofuran;

[0029] (3) At a water bath condition at 25 ° C, the three flask of the magnetic stirring step (2) for 3 h, resulting in the silicone self-repairing antifouling material.

Embodiment 3

[0031] The process of preparing the silicone self-repairing antifouling material according to the present embodiment is:

[0032] (1) 0.5 g of melamine and mass percentage concentration of 25% were added to the three flask, and magnetically stirred at 20 ° C for 2 h;

[0033] The amino content of melamine is 1.2 × 10 -2 Mol, the mass of xenzophenylene is aldehyde is 1.62 g, and the aldehyde group in aqueous xenobenzene trihyde is 3.0 × 10 -2 MOL, the molar ratio of the amino functional group and the aldehyde functional group is 0.4;

[0034] (2) PDMS and 10 ml of tetrahydrofuran were added 90.0 g of a molecular weight of 7000 g / mol to the three flasks of step (1);

[0035] (3) At a water bath condition at 25 ° C, the three flask of the magnetic stirring step (2) for 3 h, resulting in the silicone self-repairing antifouling material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com