High temperature resistant separant for compound board and preparation method thereof

A technology of release agent and clad plate, used in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of low alumina adhesion and affect the bonding quality of zirconium steel, and achieve strong adhesion, not easy to precipitate and disperse good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

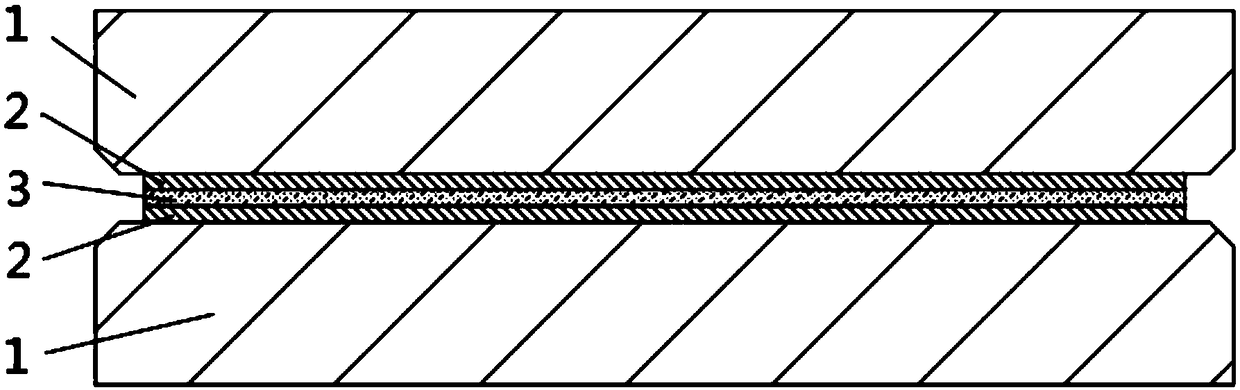

Image

Examples

Embodiment 1

[0019] 1. A high temperature-resistant release agent for a composite board, the release agent is formed by mixing alumina powder and phenolic resin powder with water, the addition of the phenolic resin powder is 10% of the alumina powder weight, the addition of water The amount is 10 times the weight of alumina powder. The particle size of the alumina powder is 1-100 μm.

[0020] 2. The preparation method of above-mentioned release agent is:

[0021] Add the formulated amount of phenolic resin powder to the formulated amount of alumina powder and stir evenly, add the formulated amount of water to the above mixed powder, mix evenly and then spray on the surface of the composite slab, the coating thickness is 2mm, air dry or heating Let dry.

Embodiment 2

[0023] 1. A high-temperature-resistant release agent for a composite board, the release agent is formed by mixing aluminum oxide powder and phenolic resin powder with water, the addition of the phenolic resin powder is 0.01% of the alumina powder weight, the addition of water The amount is 1 times the weight of alumina powder. The particle size of the alumina powder is 1-100 μm.

[0024] 2. The preparation method of above-mentioned release agent is:

[0025] Add the formulated amount of phenolic resin powder to the formulated amount of alumina powder and stir evenly, add the formulated amount of water to the above mixed powder, mix evenly and spray on the surface of the composite slab with a coating thickness of 1mm, air dry or heating Let dry.

Embodiment 3

[0027] 1. A high-temperature-resistant release agent for a composite board, the release agent is formed by mixing aluminum oxide powder and phenolic resin powder with water, the addition of the phenolic resin powder is 1% of the weight of the aluminum oxide powder, and the addition of water The amount is 5 times the weight of alumina powder. The particle size of the alumina powder is 1-100 μm.

[0028] 2. The preparation method of above-mentioned release agent is:

[0029] Add the formulated amount of phenolic resin powder to the formulated amount of alumina powder and stir evenly, add the formulated amount of water to the above mixed powder, mix evenly and then spray on the surface of the composite slab with a coating thickness of 1.5mm, air dry or Heat to air dry.

[0030] Dispersive performance

[0031] In the process of preparing the release agent in Example 1-3, the performance of the mixed powder when mixed with water was observed, and it was found that when mixed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com