Device and method for preparing ammonia gas based on chemical chain reaction

A chemical chain, ammonia technology, applied in chemical instruments and methods, ammonia preparation/separation, chemical/physical processes, etc., can solve problems such as insufficiency, prevent energy loss, improve economy, and uniform temperature distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

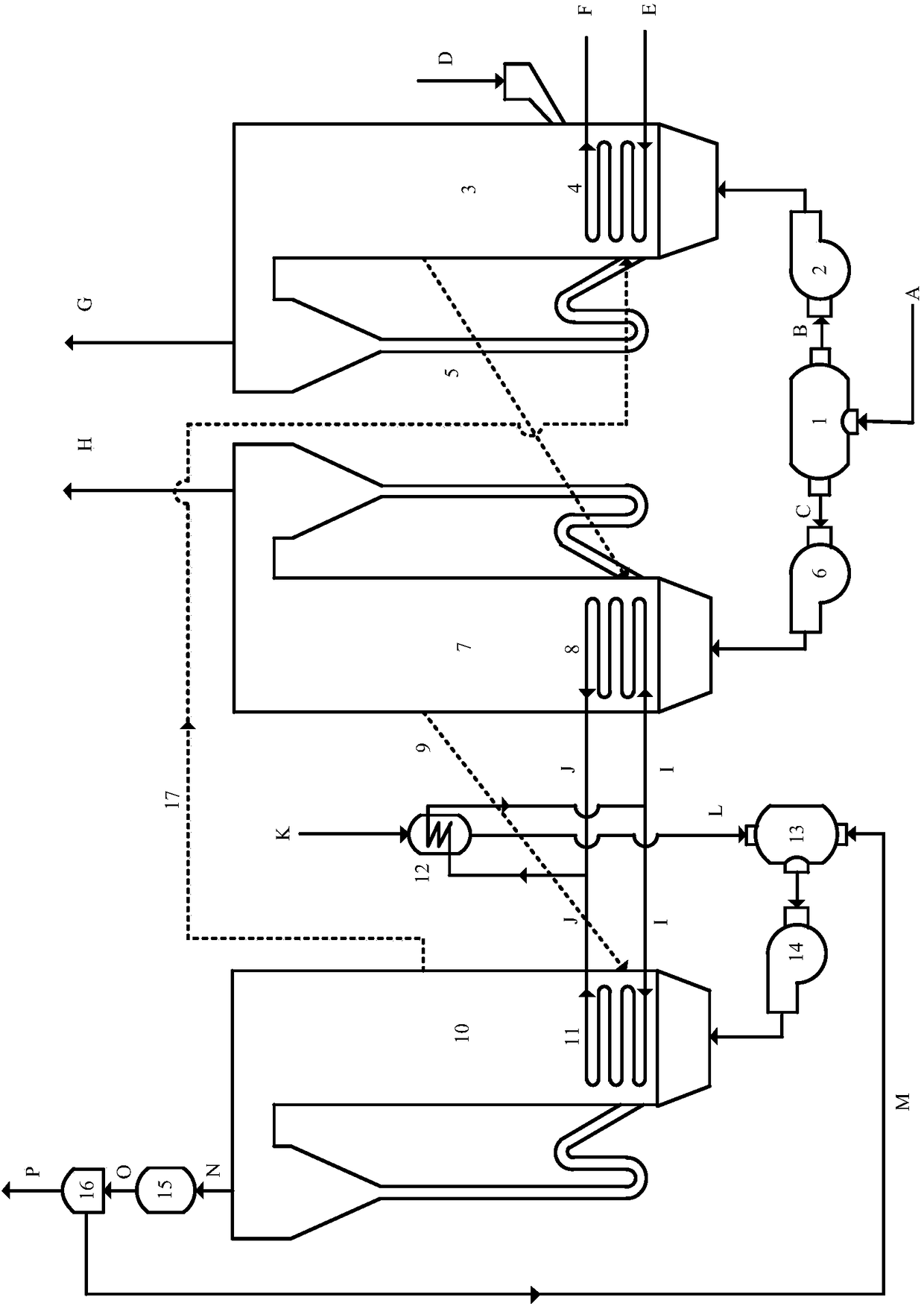

[0034] Below in conjunction with accompanying drawing, the present invention will be further described

[0035] like figure 1 As shown, the device for preparing ammonia based on the chemical chain reaction consists of an air separator:

[0036] Air separator 1, booster fan I2, nitrogen absorption reactor 3, buried tube heat exchanger I4, material circulation device I5, booster fan II6, carbon removal reactor 7, buried tube heat exchanger II8, material circulation Device II9, nitrogen release reactor 10 buried tube heat exchanger III11, steam generator 12, gas mixer 13, circulation fan 14, drying device 15, pressure device 16, material circulation device III17; among them, the air separator 1 The separated nitrogen and nitrogen-oxygen mixed gases are respectively connected to the bottom of the nitrogen absorption reactor 3 and the carbon removal reactor 7 through the booster fan I2 and the booster fan II6 through two outlets, and the middle part of the nitrogen absorption reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com