FA@CNTs reinforced foam cement insulation board

A technology of foamed cement and thermal insulation board, which is applied in the field of building materials, can solve the problems of low compressive strength, poor thermal insulation performance, etc., and achieve good foaming effect, good thermal insulation performance, and low dry apparent density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

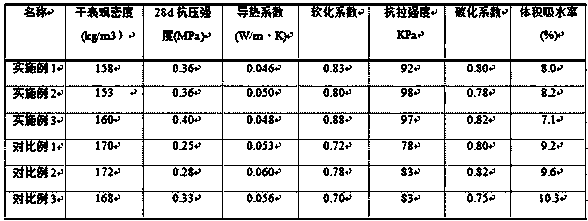

Embodiment 1

[0022] A FA@CNTs reinforced foamed cement insulation board, including the following raw materials in parts by mass:

[0023] Ordinary Portland cement 75 parts, fly ash 17.5 parts, FA@CNTs 2 parts (of which FA-CNTs content is 0.4 parts), silica fume 3 parts, calcium stearate 0.5 parts, A-3 1.7 parts, polypropylene 0.1 part of fiber, 0.06 part of water reducer, 5 parts of vinyl acetate-ethylene copolymer emulsion, 6 parts of hydrogen peroxide, and 32 parts of water.

[0024] The preparation method comprises the following steps:

[0025] 1) Dissolve FA@CNTs (the content of FA-CNTs is 20%) in water, ultrasonically disperse for 2 hours and set aside;

[0026] 2) Accurately measure and batch the above-mentioned raw materials;

[0027] 3) Add ordinary Portland cement, fly ash, silica fume, early strength agent, fiber, polymer emulsion, foam stabilizer, water reducing agent, and water (water temperature 38~50°C) into the high-speed mixer with a high-speed mixer Stir internally for ...

Embodiment 2

[0032] A FA@CNTs reinforced foamed cement insulation board, including the following raw materials in parts by mass:

[0033] Ordinary Portland cement 50 parts, fly ash 5 parts, FA@CNTs 1 part (of which FA-CNTs content is 0.2 parts), silica fume 2 parts, calcium stearate 0.3 parts, A-3 1 part, polypropylene 0.025 parts of fiber, 0.025 parts of water reducer, 2.5 parts of styrene-acrylate copolymer emulsion, 2.5 parts of hydrogen peroxide, and 18 parts of water. Concrete preparation steps are identical with embodiment 1.

Embodiment 3

[0037] A FA@CNTs reinforced foamed cement insulation board, including the following raw materials in parts by mass:

[0038] Ordinary Portland cement 100 parts, fly ash 30 parts, FA@CNTs 3.5 parts (of which FA-CNTs content is 0.7 parts), silica fume 5 parts, lead stearate 0.8 parts, A-3 3 parts, polypropylene 0.2 parts of fiber, 0.1 part of water reducer, 7 parts of ethylene-vinyl acetate copolymer emulsion, 9 parts of hydrogen peroxide, and 50 parts of water. Concrete preparation steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com