Polyphenol mixture recycling purification technology

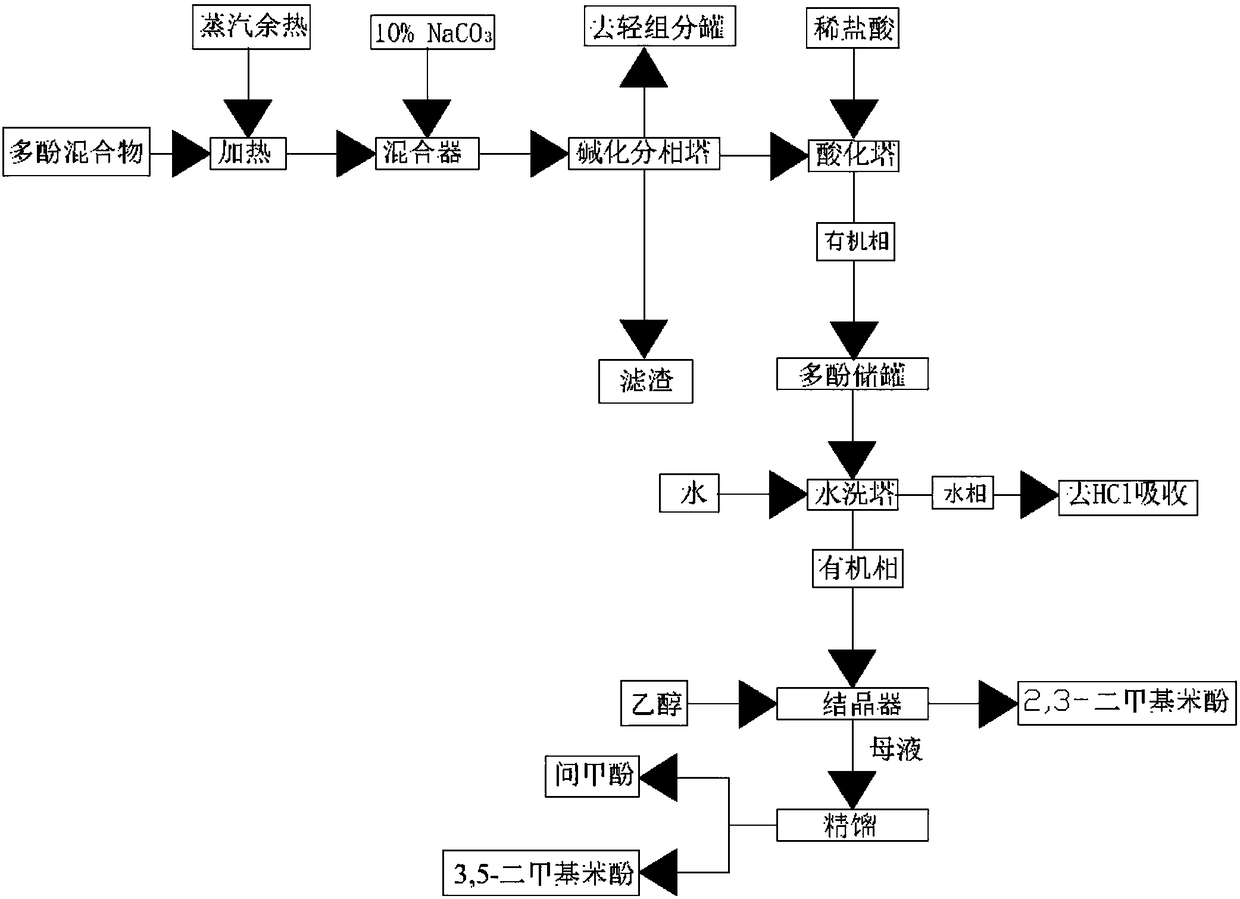

A mixture and resource-based technology, applied in the field of purification technology, can solve problems such as difficult processing and similar component structures, and achieve the effects of improving economic benefits, reducing environmental pollution, improving quality and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Definition of polyphenol mixture: The components of the catalytic cracking products of isophorone under the vacuum condition of -0.1Mpa, and the temperature at the top of the distillation column is lower than 45°C are collectively referred to as light components, and these light components are naturally cooled Afterwards, some substances will crystallize out, and this part of substances precipitated in the form of crystals is collectively referred to as a polyphenol mixture. From the perspective of material composition, its composition includes: 25% m-cresol, 40% 2,4-dimethylphenol, 25% 3,5-dimethylphenol and 10% impurities, impurities include 2, 5-Dimethylphenol and 3,4-Dimethylphenol and various other components. In the process of catalytic cracking of isophorone, in addition to the main substance 3,5-dimethylphenol, various by-products will be produced, such as 2,3-dimethylphenol, 2,4-dimethylphenol, 2 , 5-dimethylphenol, 2,6-dimethylphenol, m-cresol, toluene, trime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com