Flow type regulator for oil-based drilling fluid as well as preparation method thereof

A flow pattern regulator, oil-based drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of inability to meet oil-based drilling fluid flow pattern regulation requirements, limited sources, and increased viscosity, etc. To achieve the effect of increasing viscosity and cutting, improving rheological properties, and increasing plastic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Weigh 6g of bentonite, and pulverize the bentonite in a pulverizer (2000rpm) for 2min, then wash and dry in turn to obtain purified soil; pulverize the purified soil, add 80mL of water to it, stir to make a stable suspension, add carbonic acid The sodium bentonite was reacted for 30 minutes, dried, ground, and sieved to obtain sodium bentonite; a quaternary ammonium salt cationic surfactant and a sulfonate anionic surfactant were selected to perform a composite modification on the sodium bentonite to obtain organic soil, wherein the modified The temperature is 75°C, the amount of quaternary ammonium salt cationic surfactant is 6mmol, the amount of sulfonate anionic surfactant is 4mmol, and the reaction time of compound modification is 1.5h; stir evenly, dry and pulverize to obtain Compound modified organic soil.

Embodiment 2

[0067] Weigh 6g of bentonite, and pulverize the bentonite in a pulverizer (2000rpm) for 2min, then wash and dry in turn to obtain purified soil; pulverize the purified soil, add 80mL of water to it, stir to make a stable suspension, add carbonic acid The sodium bentonite was reacted for 30 minutes, dried, ground, and sieved to obtain sodium bentonite; a quaternary ammonium salt cationic surfactant and a sulfonate anionic surfactant were selected to perform a composite modification on the sodium bentonite to obtain organic soil, wherein the modified The temperature is 85°C, the amount of quaternary ammonium salt cationic surfactant is 8mmol, the amount of sulfonate anionic surfactant is 6mmol, and the reaction time of compound modification is 2h; stir evenly, dry and pulverize to obtain compound Modified organic soil.

Embodiment 3

[0069] Weigh 6g of bentonite, and pulverize the bentonite in a pulverizer (2000rpm) for 2min, then wash and dry in turn to obtain purified soil; pulverize the purified soil, add 80mL of water to it, stir to make a stable suspension, add carbonic acid The sodium bentonite was reacted for 30 minutes, dried, ground, and sieved to obtain sodium bentonite; a quaternary ammonium salt cationic surfactant and a sulfonate anionic surfactant were selected to perform a composite modification on the sodium bentonite to obtain organic soil, wherein the modified The temperature is 95°C, the amount of quaternary ammonium salt cationic surfactant is 10mmol, the amount of sulfonate anionic surfactant is 8mmol, and the reaction time of composite modification is 2.5h; stir evenly, dry and pulverize to obtain Compound modified organic soil.

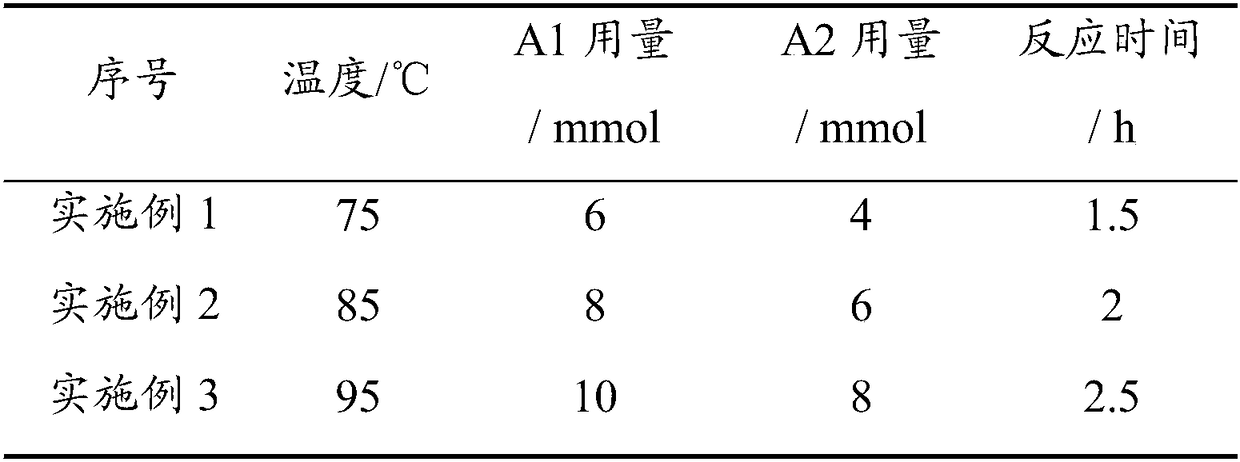

[0070] The concrete formula of above-mentioned each example is as shown in table 1 below:

[0071] Table 1 Experimental synthesis reaction conditions

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com