Household hand-held small button-sewing machine based on four-bar linkage mechanism

A four-bar linkage mechanism and hand-held technology, which is applied in the direction of sewing equipment, sewing machine components, program-controlled sewing machines, etc., can solve the problems of low automation of four-hole buttons and the inability to automatically nail buttons, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

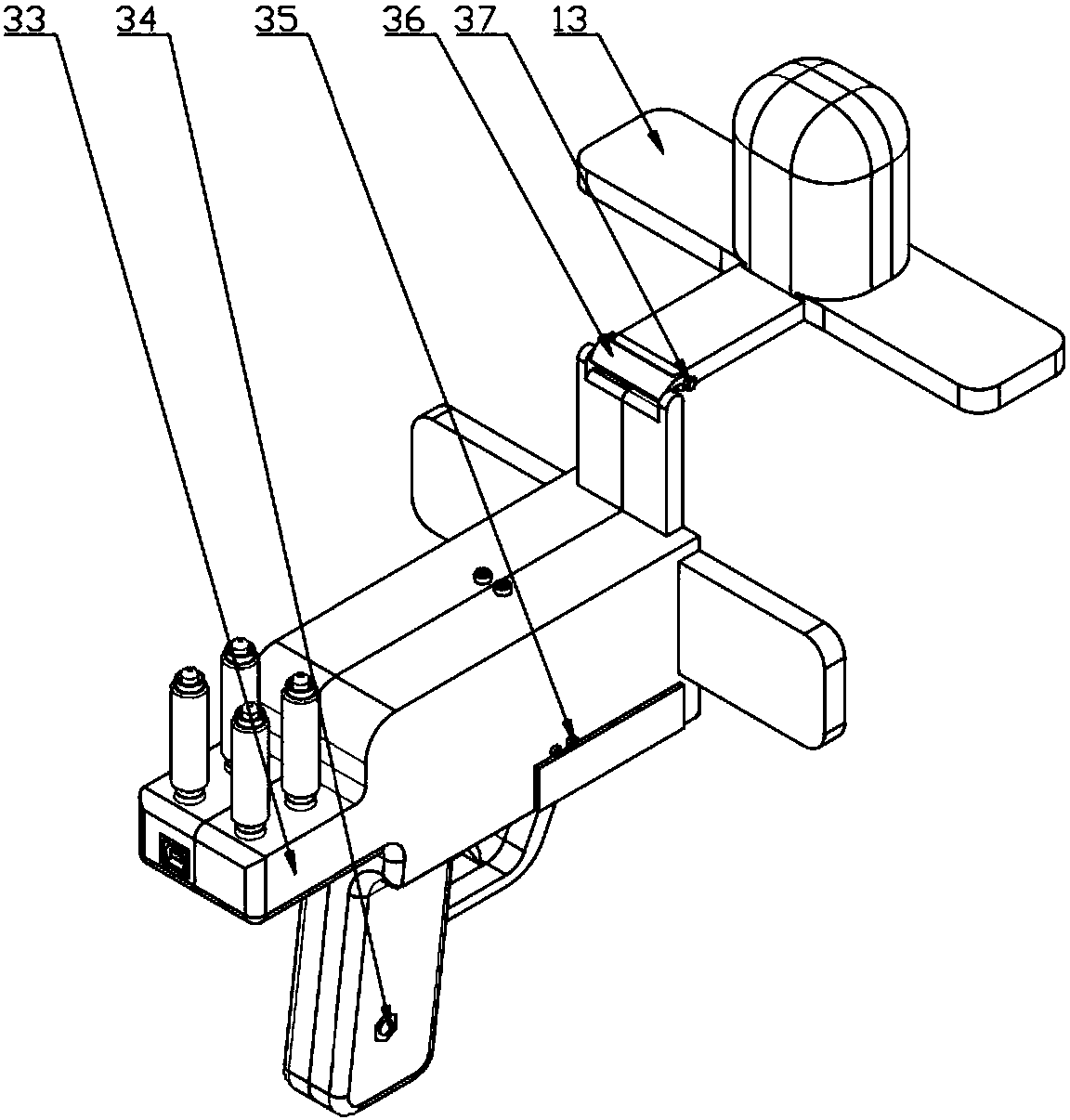

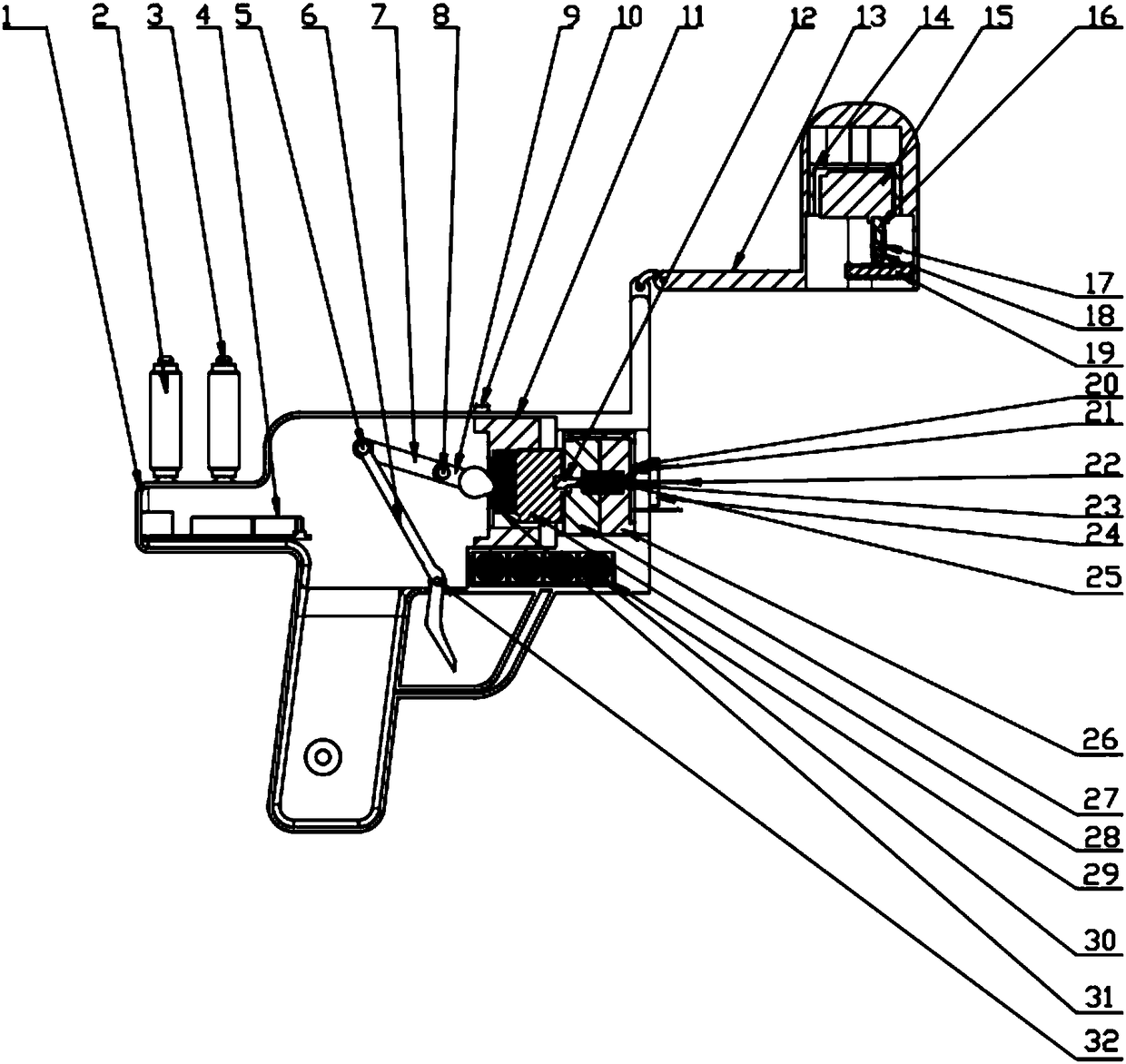

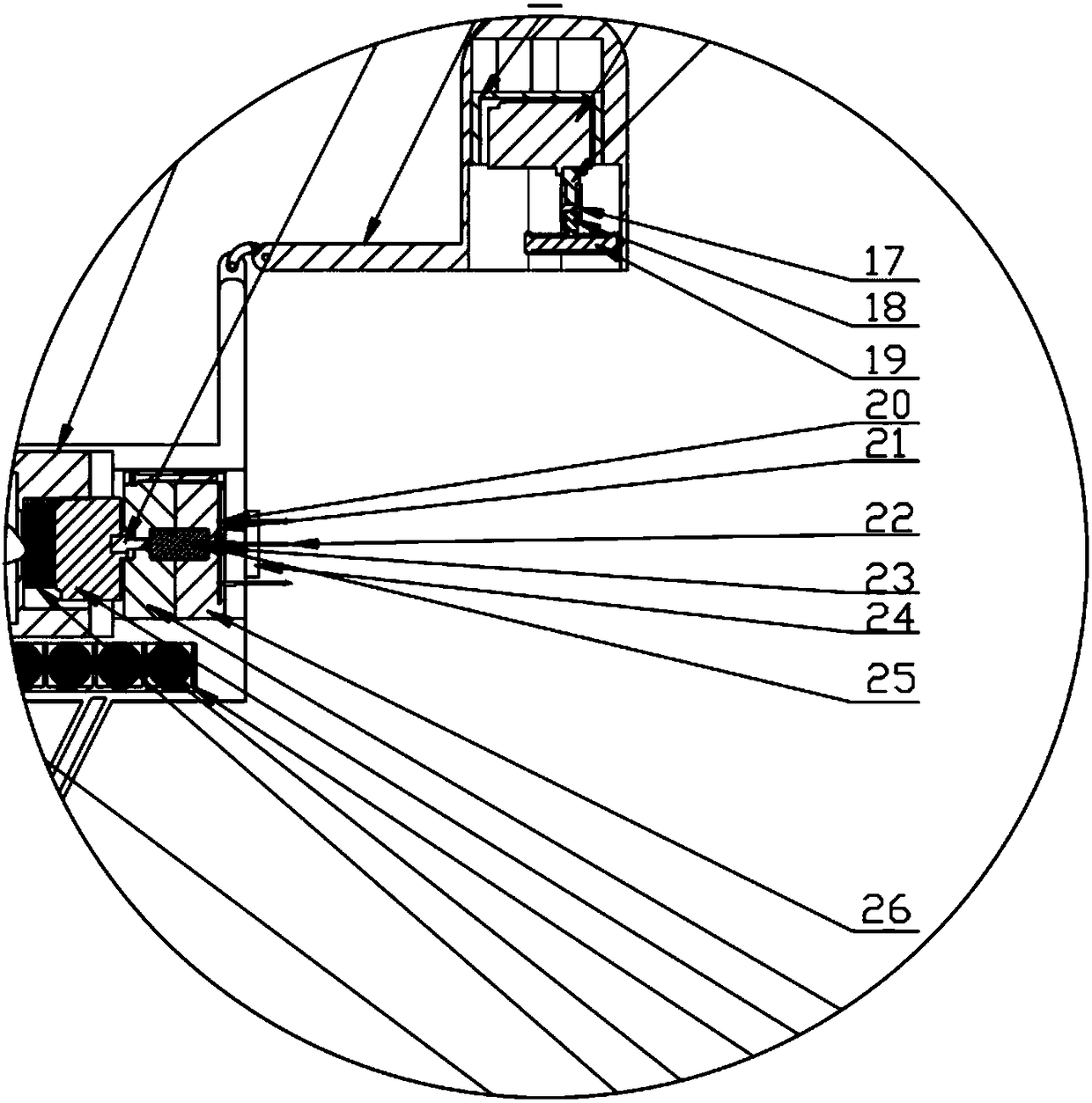

[0019] The household hand-held small button nailing machine is mainly composed of the left housing (1), sewing machine thread (2), sewing machine thread sleeve shaft (3), Arduino microcontroller (4), rocker connecting rod rotating shaft (5), trigger (6), connecting rod (7), crank connecting rod shaft (8), crank cam (9), hexagon socket head cap screw (10), cylindrical reciprocating piston fixing frame (11), center stepping motor output shaft (12), Clothes fixing head (13), eccentric stepping motor fixing frame (14), eccentric stepping motor (15), eccentric stepping motor output shaft (16), shaft coupling (17), winding plane plate (18), Four-hole button (19), lead screw nut (20), lead screw (21), nail button pin (22), driven bevel gear (23), disc magnet (24), distance-adjustable motor output shaft (25 ), the right half of the cylindrical reciprocating piston (26), the left half of the cylindrical reciprocating piston (27), the center stepping motor (28), the battery box (29), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com