Matrix decomposition-based lensless holographic microscopic speckle noise removing method and device

A technology of matrix decomposition and speckle noise, which is applied in measurement devices, material analysis, and material analysis through optical means, can solve the problem that the system is difficult to deal with speckle noise, periodic fringe interference, etc. The effect of resolution and high-precision dynamic 3D imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

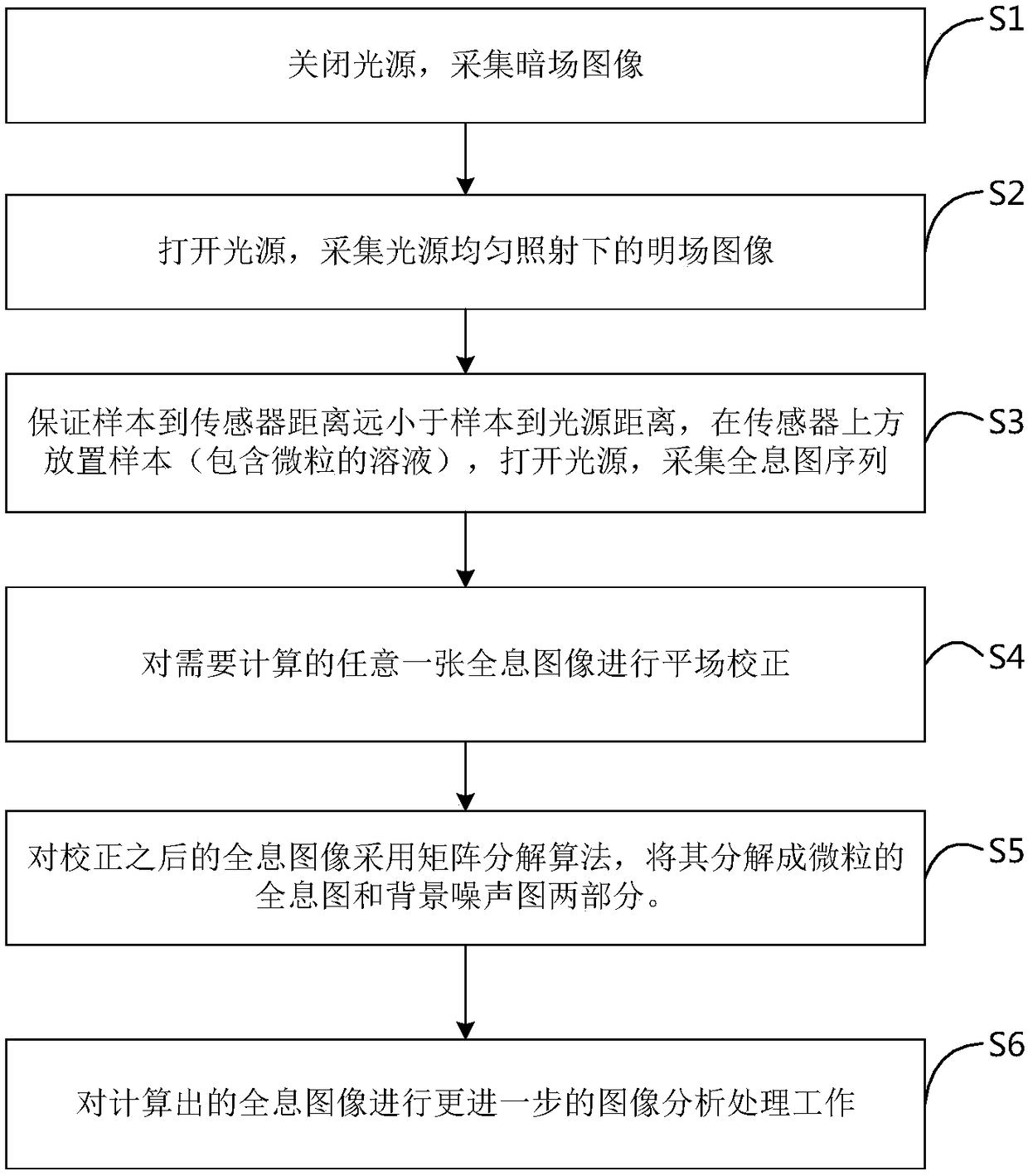

[0029] see figure 1 , the present invention removes the speckle noise method in holographic microscopic imaging, and the steps are as follows:

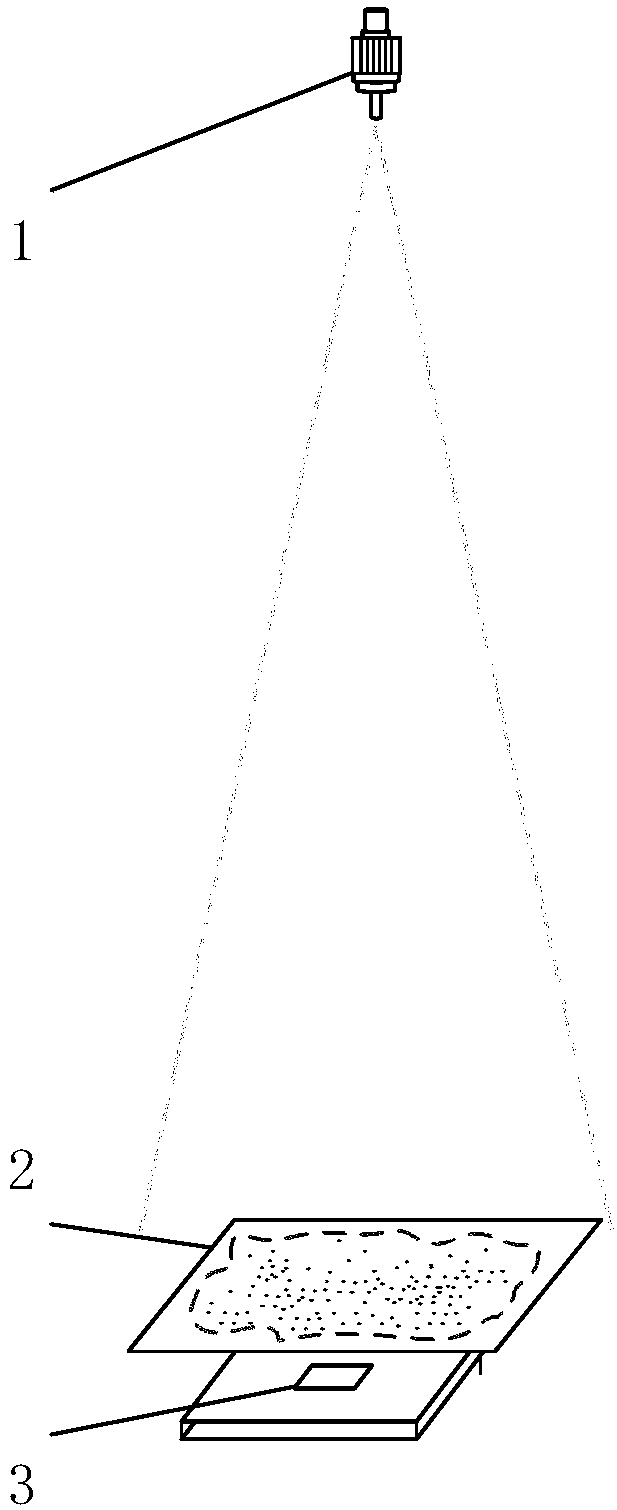

[0030] S1: Turn off the light source, and use the sensor 3 to capture dark field images under dark room conditions (without ambient stray light). Lensless holographic microscopy device for capturing images see figure 2 , including coherent light source 1, sensor 3 and so on. The irradiation range of the light source covers the entire effective photosensitive area of the sensor 3 .

[0031] S2: Turn on the light source, and collect bright field images under uniform illumination of the light source under dark room conditions (without ambient stray light).

[0032] S3: Place sample 2 (solution sample or other samples) above sensor 3 . The distance from sample 2 to sensor 3 is much smaller than the distance from sample 2 to coherent light source 1 . On the one hand, this makes the incident wave propagating from the sample 2 to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com