Highly stable hollow molecular sieve, selective catalyst prepared by utilizing the hollow molecular sieve and application thereof

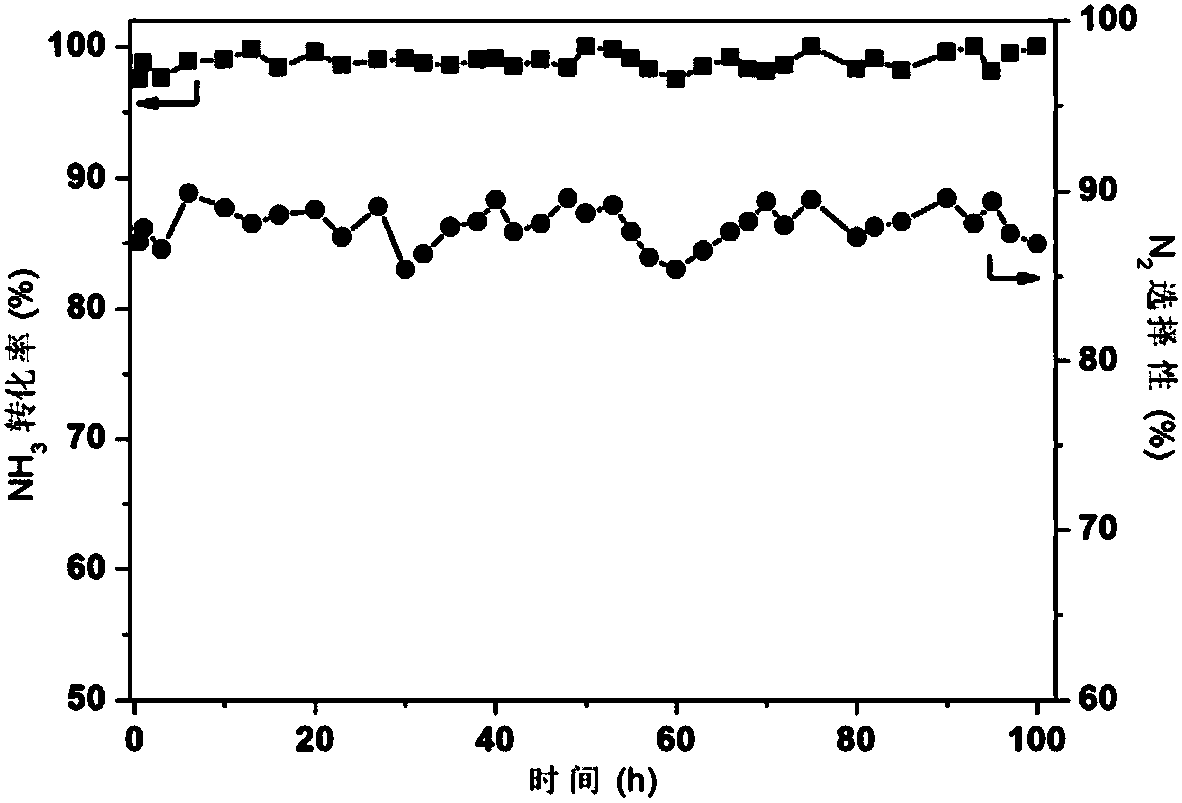

A high-stability, molecular sieve technology, applied in the field of selective catalysts and high-stability hollow molecular sieves, can solve the problems of short service life of anti-sulfur and water-resistance, the catalyst cannot have both high and low temperature activity, etc., and achieves large filling amount and excellent catalytic performance. Active, promising effect for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of hollow ZSM-5 molecular sieve

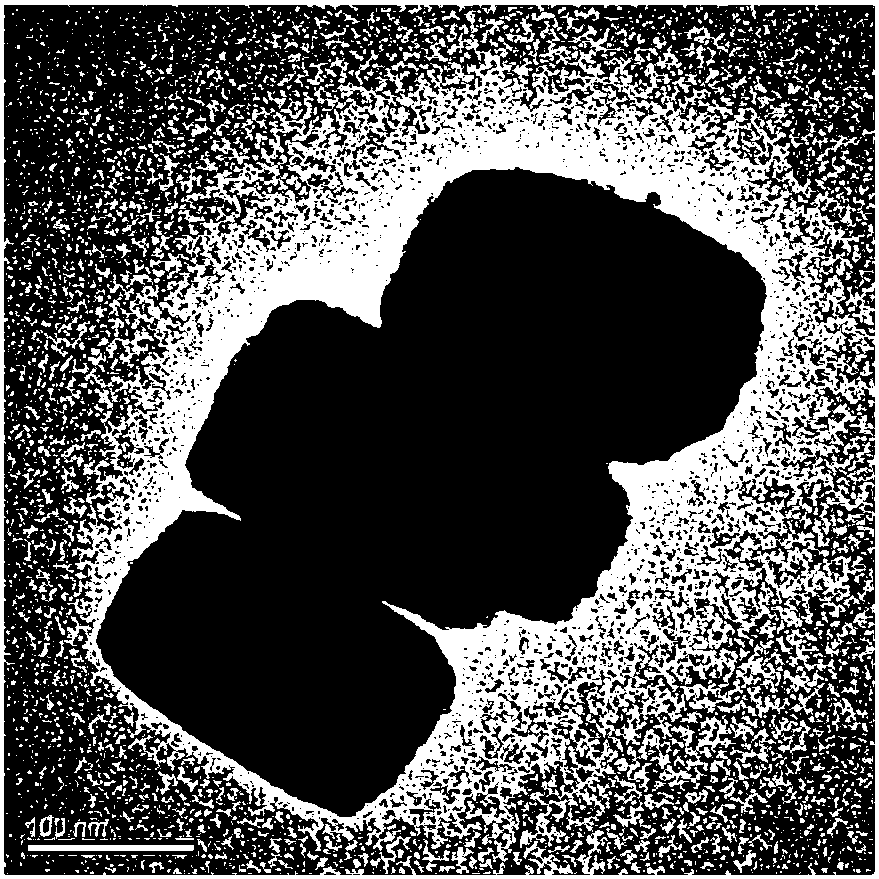

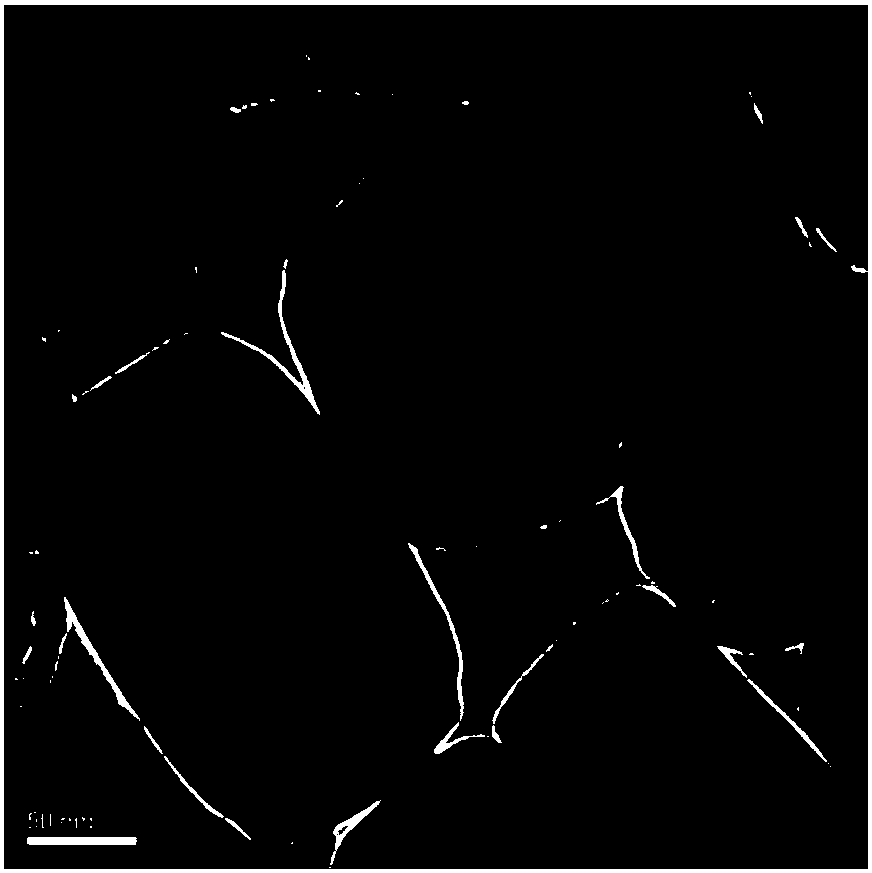

[0040] Add 1.5g ZSM-5 molecular sieve (SiO2:Al2O3=20:1 (molar ratio)) to 60mL deionized water and 40mL absolute ethanol mixture, stir for 30min; add 15mL NaOH (0.1mol / L) solution, stirred at 30°C for 1h; added 10mL of TPAOH to the above solution, and stirred for 30min; put the above solution into a reaction kettle, sealed, and crystallized at 50°C. Dry under vacuum for 10h, calcined at 650°C for 10h to obtain hollow ZSM-5 molecular sieve (see figure 1 ).

[0041] It can be seen from the figure that the overall structure of the ZSM-5 molecular sieve has not been destroyed, and a hollow molecular sieve has been formed.

[0042] (2) Preparation of Ag / hollow ZSM-5 catalyst

[0043] Add 1.0g hollow ZSM-5 molecular sieve to 100mL deionized water, keep the absolute pressure of the rotary evaporator at 0.06MPa, the rotation speed at 150r / min, and the temperature at 60°C until it evaporates to dryness; add 0.1575g of silver n...

Embodiment 2

[0046] (1) Preparation of hollow Beta molecular sieve

[0047] Add 2g of Beta molecular sieve (SiO2:Al2O3=100:1) into 70mL of deionized water and 50mL of absolute ethanol mixture, stir for 60min; add 20mL of KOH (0.1mol / L) solution to the above solution, and stir at 30°C 4h; add 15mL of TPABr to the above solution, stir for 30min; put the above solution into the reaction kettle, seal it, and crystallize it at 80°C. Calcined for 12 hours to obtain a hollow Beta molecular sieve.

[0048] (2) Preparation of Ag / hollow Beta catalyst

[0049] Add 0.8g of hollow Beta molecular sieves to 80mL of deionized water, keep the absolute pressure of the rotary evaporator at 0.09MPa, the rotation speed at 300r / min, and the temperature at 80°C until evaporated to dryness; add 0.0124g of silver acetate to 70mL of deionized water , stirred for 40 minutes until completely dissolved; the silver acetate solution was added to a rotary evaporating flask equipped with a hollow Beta molecular sieve, a...

Embodiment 3

[0051] (1) Preparation of hollow HY molecular sieve

[0052] Add 2g HY molecular sieve (SiO2:Al2O3=40:1) into 70mL deionized water and 50mL absolute ethanol mixture, stir for 90min; add 40mL Na2CO3 (0.1mol / L) solution to the above solution, stir at 30°C 3h; add 5mL of TEA to the above solution, stir for 30min; put the above solution into the reaction kettle, seal it, and crystallize it at 70°C. Calcined for 8 hours to obtain hollow HY molecular sieves.

[0053] (2) Preparation of Ag / hollow HY catalyst

[0054] Add 1g of hollow HY molecular sieve into 80mL of deionized water, keep the absolute pressure of the rotary evaporator at 0.085MPa, the rotation speed at 200r / min, and the temperature at 70°C until evaporated to dryness; add 0.1445g of silver sulfate into 70mL of deionized water, Stir for 40 minutes until completely dissolved; add the silver sulfate solution into the rotary evaporator bottle equipped with hollow HY molecular sieves, keep the absolute pressure of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com