Energy-saving environmental-protection fertilizer irrigation equipment

An energy-saving, environmentally friendly and chemical fertilizer technology, which is applied in the fields of manure treatment, fertilization devices, liquid fertilizer distribution, etc., can solve the problems of poor irrigation effect of chemical fertilizers, waste of water by equipment, etc., to promote the accumulation of organic matter content, improve the utilization rate, and increase the water absorption. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

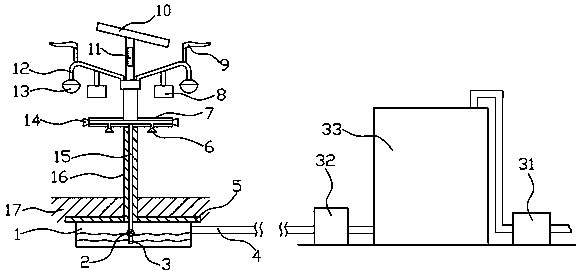

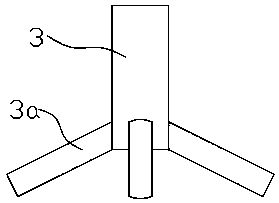

[0022] Such as Figure 1~5 As shown, the energy-saving and environment-friendly chemical fertilizer irrigation equipment includes a water tank 1, the water tank 1 is buried inside the soil layer 17, the upper end of the water tank 1 is connected with a vertical pole 16, the surface of the vertical pole 16 is connected with a horizontal column 7, and the upper end of the horizontal column 7 is provided with a vertical The boom 12 connected to the rod 16, the upper end of the boom 12 is provided with a solar panel 10 connected to the top of the vertical rod 16, the side of the box 1 is connected to the water inlet pipe 4, the water inlet pipe 4 is connected to the water pump II32, and the water pump II32 is connected to the mixing box 33 , the mixing tank 33 is connected to the water pump I31 through a conduit. Part of the water storage is realized by burying the water tank 1. The overall structure of the equipment is compact, the space occupied is small, and it can be used in c...

Embodiment 2

[0032] This embodiment is a further optimization scheme on the basis of Example 1: the fiber ball 30 is made up of fiber material, and the preferred preparation method of the fiber material shown is: by weight, get 10 parts of corn cellulose and 4 parts of bamboo wood element, added to 13 parts of acetylacetone and 0.02 parts of 1,2-diphenylethylenediamine, stirred to dissolve completely to obtain spinning solution; the spinning solution was placed in the syringe of the high-voltage electrospinning device, and used The air pump extrudes the spinning liquid from the syringe at a flow rate of 4 μL / min, and then sprays it out from the spinneret. The sprayed spinning liquid jet is solidified to form nanofibers, which are arranged in a disordered manner on the collecting plate. Take off the plate to obtain nanofibers; the voltage of the high-voltage electrostatic generator is 11kV, the distance between the spinneret of the electrospinning device and the collecting plate grounded is ...

Embodiment 3

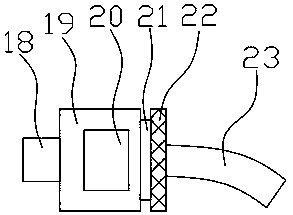

[0035] Such as Figure 1~5 As shown, the working principle of this equipment is: the water pump I31 pumps the irrigation water into the mixing tank 33, and adds an appropriate amount of chemical fertilizer into the mixing tank 33, and the mixing tank 33 mixes the fertilizer and irrigation water evenly, and the water pump II32 passes the mixed water through the mixing tank 33. The water pipe 4 is pumped into the water tank 1, and the small water pump 3 sucks the mixed water into the aqueduct 15 through the water suction pipe 3, and the mixed water in the aqueduct 15 is sprayed out from the small spout 6 and the large spout 14 to realize chemical fertilizer irrigation. During the irrigation process, the control The box 20 controls the continuous rotation of the spray pipe 23, so as to realize the gradual irrigation of long and short distances and improve the irrigation effect of chemical fertilizers. The solar panel 10 converts light energy into electric energy and stores it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com