Device and method for activating molecular oxygen by electrocatalysis to treat persistent organic wastewater

An organic waste water, refractory technology, applied in the field of environmental technology and water treatment, can solve the problems of long treatment time of medium and high concentration organic waste water, limited concentration of strong oxidizing substances, lower reaction temperature and pressure, etc., to achieve compact equipment and easy control. , the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

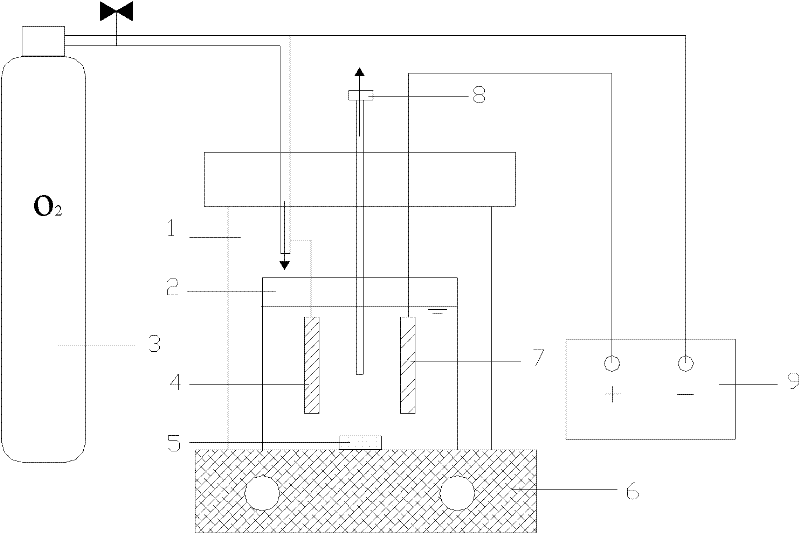

Image

Examples

Embodiment 1

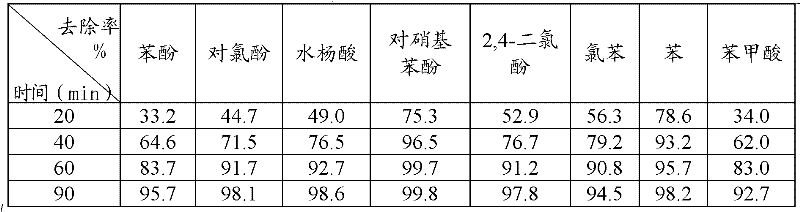

[0022] Embodiment 1. Comparison of the removal effect of different organic matter

[0023] Reaction solution volume: 500ml

[0024] Reaction solution concentration: 1mM

[0025] Electrolyte concentration: 50mM Na 2 SO 4

[0026] Anode plate area: 48cm 2

[0027] Cathode plate area: 48cm 2

[0028] Oxygen pressure: 0.5MPa

[0029] Response time: 90min

[0030] Response current: 0.100A

[0031] The anode material is titanium-based lead dioxide, and the cathode material is activated carbon fiber felt modified by iron metal porphyrin. The specific surface area of the activated carbon fiber felt is 1200m 2 / g.

[0032] Add organic waste water directly into the electrolysis reactor. The distance between the cathode and anode in the reactor is fixed. After adding the waste water, close the reaction box, feed oxygen, adjust the oxygen pressure, and pre-pressurize for 15 minutes to make the oxygen dissolve and reach saturation. Turn on the magnetic stirrer and the regulat...

Embodiment 2

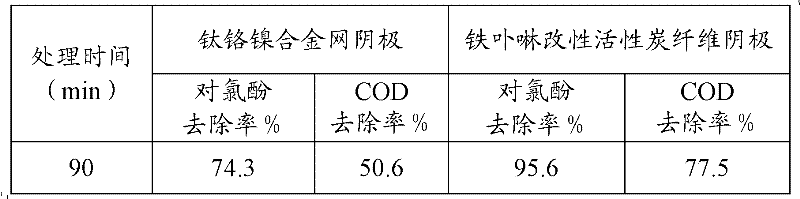

[0037] Embodiment 2. For the comparison of different cathode materials

[0038] Reaction solution volume: 500ml

[0039] Reaction solution concentration: 8mM p-chlorophenol

[0040] Electrolyte concentration: 50mM Na 2 SO 4

[0041] Anode plate area: 48cm2

[0042] Cathode plate area: 48cm 2

[0043] Oxygen pressure: 0.5MPa

[0044] Response time: 90min

[0045] Response current: 0.100A

[0046] The anode material is titanium-based lead dioxide, and the cathode materials are activated carbon fiber felt modified by iron metal porphyrin and titanium-chromium-nickel alloy mesh.

[0047] Add high-concentration organic wastewater directly into the electrolysis reactor. The distance between the cathode and anode in the reactor is fixed. After adding wastewater, close the reaction box, feed oxygen, adjust the oxygen pressure, and pre-pressurize for 15 minutes to make the oxygen dissolve and reach saturation. Turn on the magnetic stirrer and the regulated DC power supply, ad...

Embodiment 3

[0052] Example 3. Comparison for different anode materials

[0053] Reaction solution volume: 500ml

[0054] Reaction solution concentration: 8mM p-chlorophenol

[0055] Electrolyte concentration: 50mM Na 2 SO 4

[0056] Anode plate area: 48cm 2

[0057] Cathode plate area: 48cm 2

[0058] Oxygen pressure: 0.5MPa

[0059] Response time: 90min

[0060] Response current: 0.100A

[0061] The anode materials are titanium-based lead dioxide and titanium-based ruthenium dioxide, and the cathode material is activated carbon fiber felt modified by iron metal porphyrin.

[0062] Add high-concentration organic wastewater directly into the electrolysis reactor. The distance between the cathode and anode in the reactor is fixed. After adding wastewater, close the reaction box, feed oxygen, adjust the oxygen pressure, and pre-pressurize for 15 minutes to make the oxygen dissolve and reach saturation. Turn on the magnetic stirrer and the regulated DC power supply, adjust the curr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com