Biological pretreatment technology of low-grade refractory gold ore

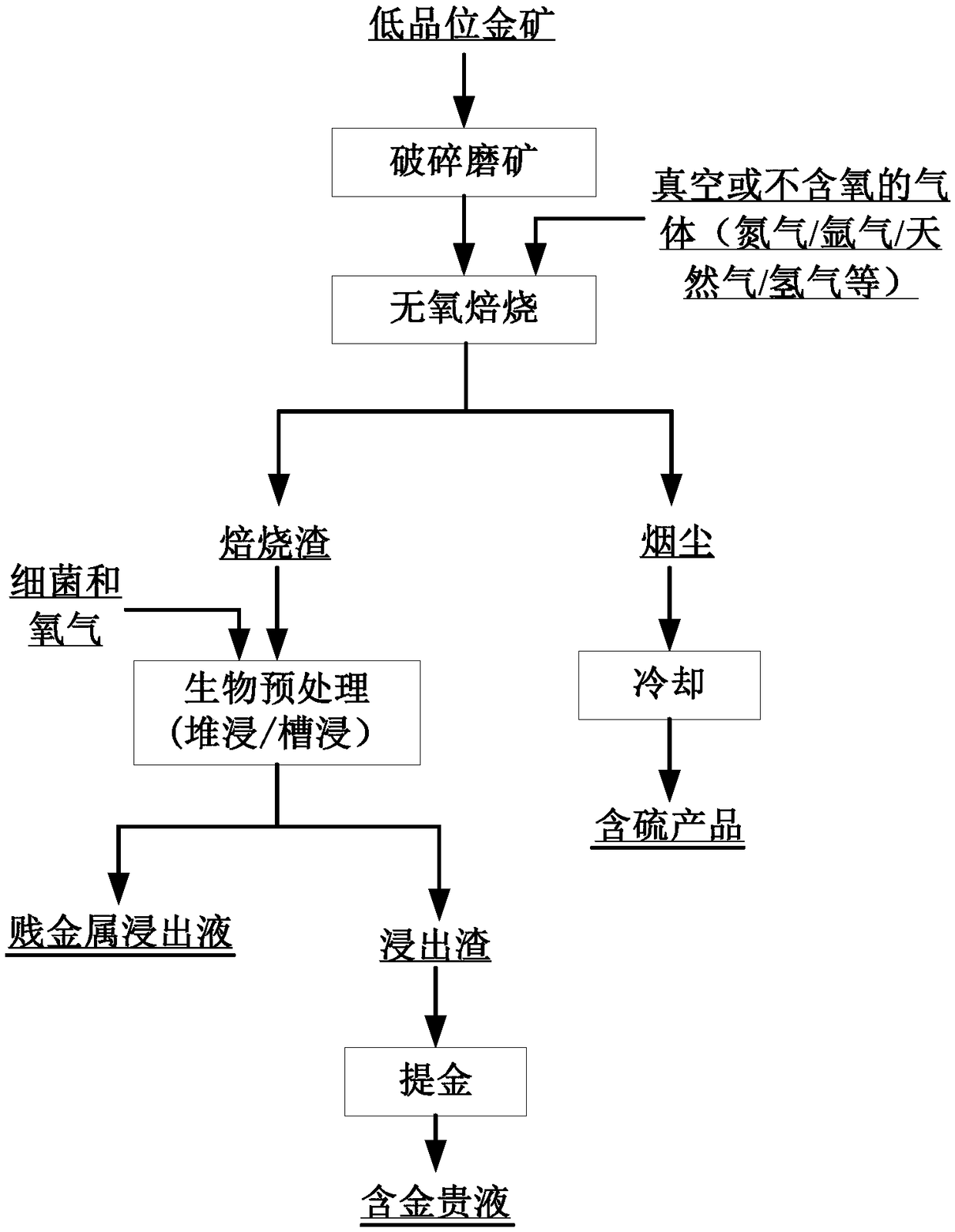

A biological pretreatment and pretreatment technology, applied in the direction of improving process efficiency, etc., can solve the problems of hindering the oxidation and dissolution of gold ore, long biological oxidation cycle, and unsuitable high sulfur content, so as to achieve significant economic and social benefits and reduce biological Poisoned, obviously advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, a refractory gold mine in Guangxi is selected. Most of the gold is wrapped in sulfide, and its composition is 1.4g / t of gold, 9.1% of iron, 1.6% of sulfur, and 1.1% of carbon. The specific operation steps and process parameters used in this example are as follows: take 100 grams of the refractory gold ore and crush it, ball mill it into powder, and the particle size is less than 20 mm, accounting for 95%, put it into a rotary kiln, put it into a closed heating, and feed nitrogen for anaerobic Roasting, the calcination temperature is controlled at 1000°C, and the calcination time is 0.25 hours. The smoke generated by roasting is cooled to obtain sulfur. The roasted slag is piled up and pretreated by bioheap leaching. The strains used are the mixed strains of Microspirillum ferrooxidans, Thiobacillus ferrooxidans, Thiobacillus sulfoxidans and Sulfolobus. Commercially available bacterial classifications can be used, such as the bacteria-containing rati...

Embodiment 2

[0051] In this embodiment, a refractory gold mine in Xinjiang is selected. The gold is wrapped in sulfide in the form of fine particles, and its composition is 10g / t gold, 8.5% iron, 3.1% sulfur, 0.7% copper, 1.8% arsenic, and 0.3% antimony. %. The specific operation steps and process parameters adopted in this example are as follows: 100 grams of this refractory gold ore is crushed, ball milled, and the particle size is less than 0.074 mm, accounting for 95%, and placed in a vacuum furnace for roasting, and the roasting temperature is controlled at 600 ° C. The calcination time is 4 hours, and the reaction residual pressure is 200Pa. Sulfur, arsenic, antimony, arsenic sulfide and antimony sulfide can be obtained by cooling the soot generated by roasting. The roasted slag is placed in the reaction kettle through pulping and adopts the pretreatment process of biological tank immersion. The mixed bacteria in the strain 4 used, that is, according to the proportion of the number ...

Embodiment 3

[0055] In this embodiment, a refractory gold mine in Liaoning is selected. The gold is wrapped in sulfide, and its composition is 0.1 g / t of gold, 5.3% of iron, 1.2% of sulfur, and 0.5% of arsenic. The specific operation steps and process parameters that this example adopts are as follows: get 100 grams of this refractory gold ore crushing, ball milling, particle size is to be less than 20mm and account for 75%, put the mixed gas of hydrogen and natural gas into heating furnace (both volumes The ratio is 1:1) for roasting, the roasting temperature is controlled at 700°C, and the roasting time is 2 hours. The soot generated by roasting is cooled to obtain products such as hydrogen sulfide. The roasted slag is piled up and pretreated by bioheap leaching. The bacteria used are in proportion to the number of bacteria: Microspiral ferrooxidans (BNCC173516) accounts for 1%, Thiobacillus ferrooxidans (BNCC170088) accounts for 40%, Sulfobacillus (BNCC173437) accounts for 34%, Sulfolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com