Formaldehyde room-temperature oxidation composite carrier catalyst prepared with sol gel-impregnation method

A composite carrier and sol-gel technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as poor effects, and achieve high product added value, The effect of simple process route and low precious metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

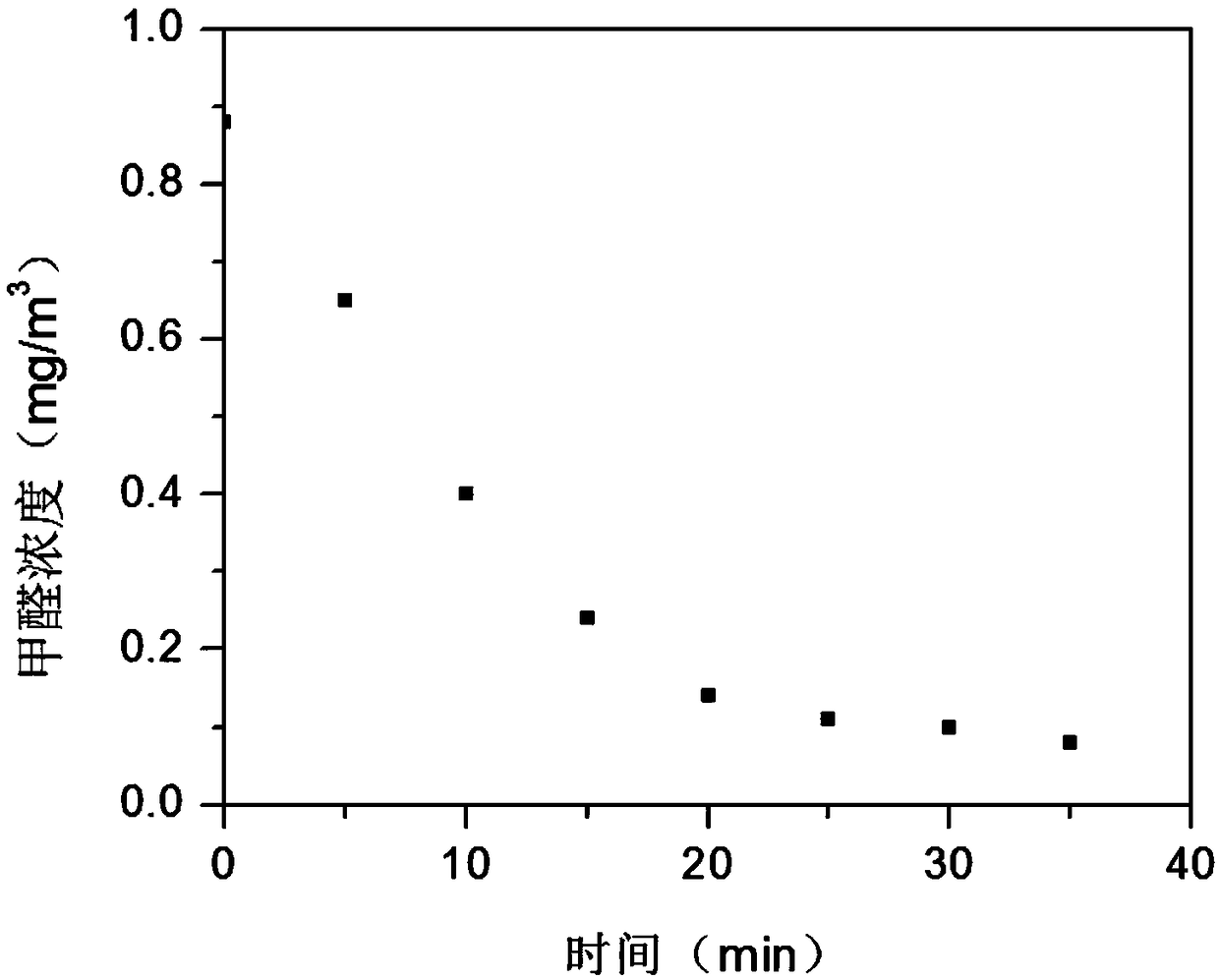

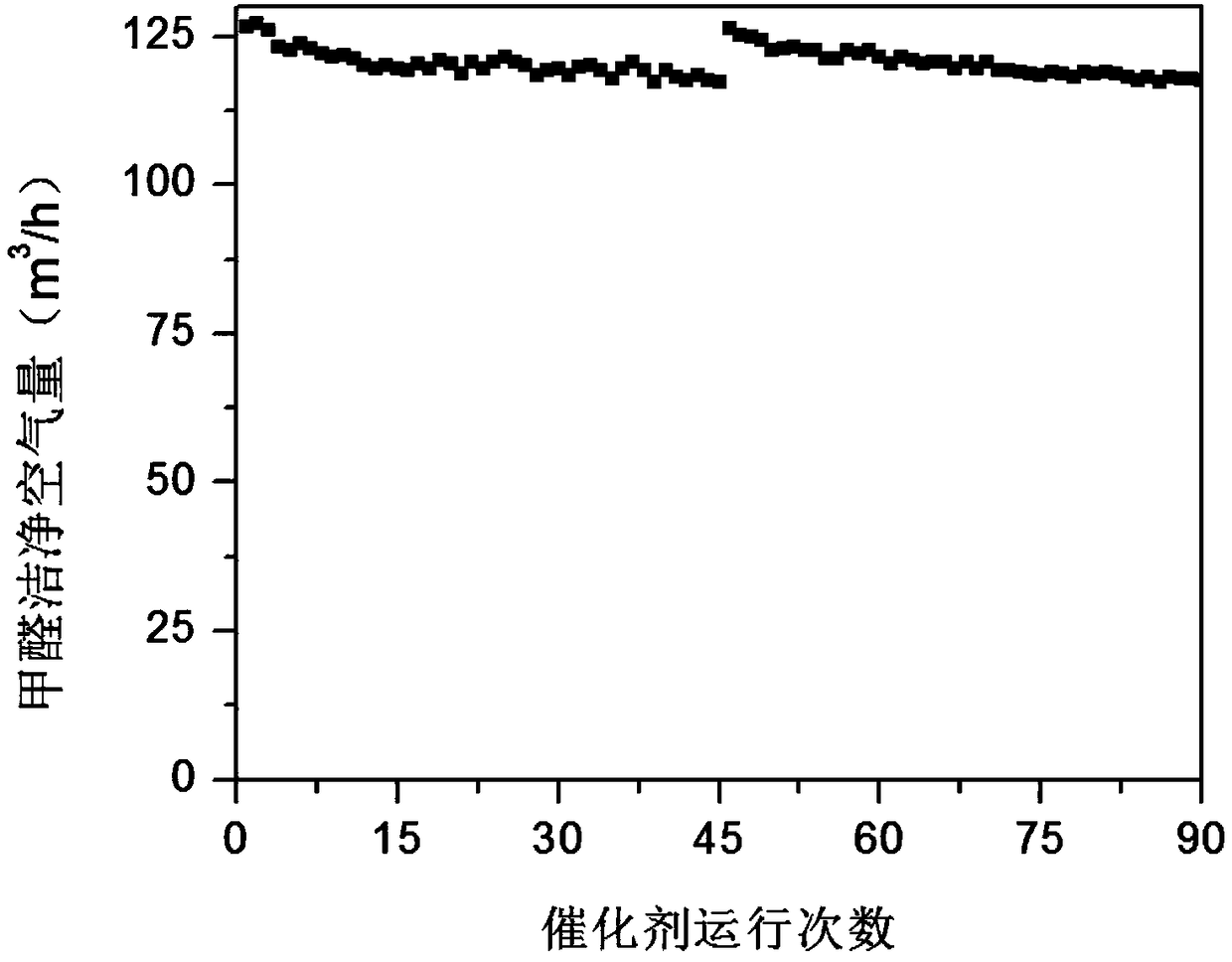

Embodiment 1

[0022] 1. According to the composition of the catalyst, it is 0.1%Pt-0.4%Na-5%TiO 2 - Activated carbon, add 120mL tetrabutyl titanate to 180mL absolute ethanol, stir evenly at room temperature to obtain solution A; mix 50mL distilled water and 250mL absolute ethanol, adjust the pH to 2-3 with concentrated nitric acid, and stir evenly at room temperature to obtain Solution B: Add 300mL of solution B dropwise to 300mL of solution A which is constantly stirring, and continue stirring to obtain a sol system. Wash the purchased columnar activated carbon with water to remove surface impurities and ash, then add 10% nitric acid aqueous solution, boil on the heating furnace for 2 hours, wash with deionized water repeatedly after cooling, put the washed activated carbon in a drying box Dry at 150°C. Then add 529.2g of pretreated columnar activated carbon into the sol system, stir to make it fully mixed, first dry at 60°C in a vacuum oven for 3 hours, and then dry at 120°C in a blast o...

Embodiment 2

[0025] 1. According to the composition of the catalyst, it is 0.2%Pt-0.8%Na-10%TiO 2 -Activated carbon, add 240mL tetrabutyl titanate to 240mL absolute ethanol, stir evenly at room temperature to obtain solution A; mix 50mL distilled water and 150mL absolute ethanol, adjust the pH to 2-3 with concentrated nitric acid, and stir evenly at room temperature to obtain Solution B: Add 200mL of solution B dropwise to 480mL of solution A which is constantly stirring, and continue stirring to obtain a sol system. Wash the purchased columnar activated carbon with water to remove surface impurities and ash, then add 10% nitric acid aqueous solution, boil on the heating furnace for 2 hours, wash with deionized water repeatedly after cooling, put the washed activated carbon in a drying box Dry at 150°C. Then add 498.4g of pretreated columnar activated carbon into the sol system, stir to make it fully mixed, first dry it in a vacuum oven at 60°C for 6 hours, and then dry it in a blast oven...

Embodiment 3

[0028] 1. According to the composition of the catalyst, it is 0.05%Pt-1%TiO 2 - Activated carbon, add 24mL tetrabutyl titanate to 72mL absolute ethanol, stir evenly at room temperature to obtain solution A; mix 75mL distilled water and 400mL absolute ethanol, adjust the pH to 2-3 with concentrated nitric acid, and stir evenly at room temperature to obtain Solution B: Add 475mL of solution B dropwise to 96mL of solution A which is constantly stirring, and continue stirring to obtain a sol system. Wash the purchased columnar activated carbon with water to remove surface impurities and ash, then add 10% nitric acid aqueous solution, boil on the heating furnace for 2 hours, wash with deionized water repeatedly after cooling, and put the washed activated carbon in a drying box Dry at 150°C. Then add 554.1g of pretreated columnar activated carbon into the sol system, stir to make it fully mixed, first dry it in a vacuum oven at 60°C for 3 hours, and then dry it in a blast oven at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com