Full-automatic coating system for conformal coating and control method of full-automatic coating system

A three-proof paint, fully automatic technology, applied in the direction of the spray device, etc., to achieve the effect of reasonable structure design, high precision and high edge definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

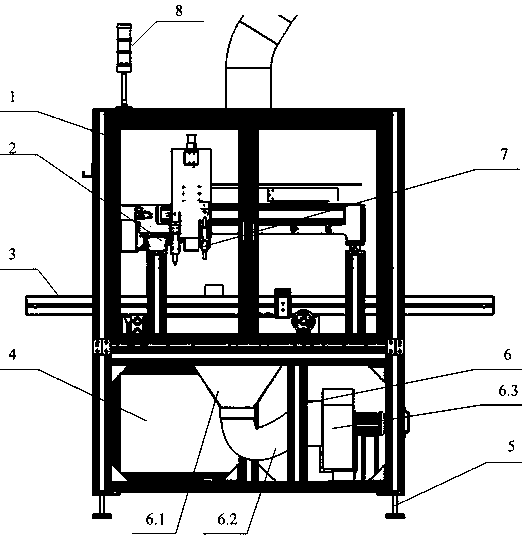

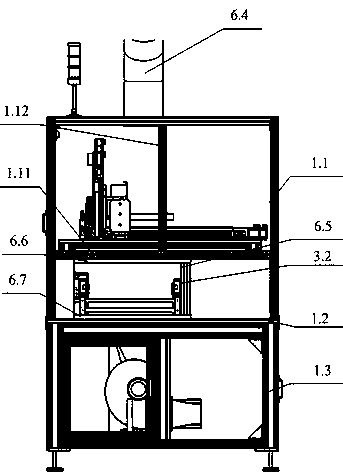

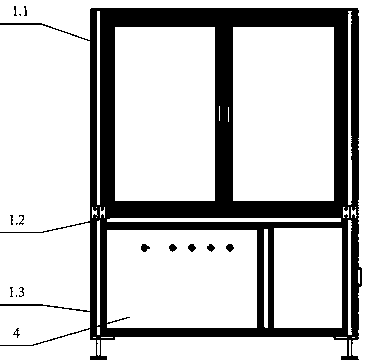

[0032] Such as Figure 1 to Figure 7 As shown, a full-automatic coating system for conformal paint includes coater frame 1, three-axis motion platform 2, PCB board transmission and positioning assembly 3, full-automatic coating system control box 4, and harmful gas filtration system for conformal paint 6 and the spray valve 7; the coating machine frame 1 includes an upper box body 1.1, an intermediate support plate 1.2 and a lower box body 1.3 and is assembled as one; the three-axis motion platform 2 is composed of a ball screw in the Z direction and a pneumatic sliding table movement assembly 2.1. The ball screw active movement assembly in the Y direction 2.2, the ball screw driven movement assembly 2.5 in the Y direction, the gantry 2.3 supporting the three-axis motion platform and the ball screw movement assembly 2.4 in the X direction are assembled; among them, The bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com