Preparation method of high-strength beta titanium alloy wire material for springs

A technology of titanium alloy wire and titanium alloy, which is applied in the direction of wire drawing die, etc., to achieve the effect of reducing cost, good size consistency, and reducing hydrogen absorption process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

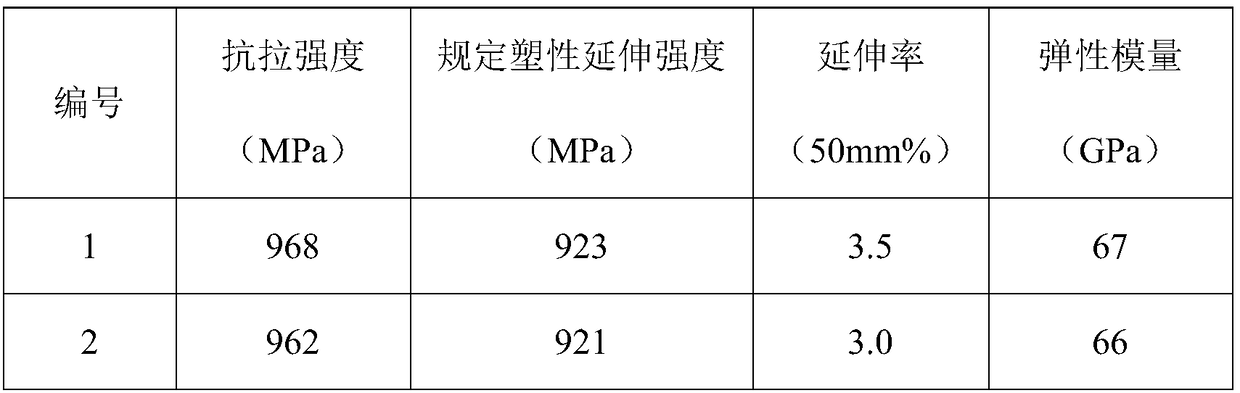

[0022] A method for preparing a β-type titanium alloy wire for springs, which uses free forging, precision forging, rolling, and hot drawing processes to prepare β-type titanium alloy wires for springs with a diameter of Ф1 mm to Ф3 mm. Specifically include the following steps:

[0023] Step 1: Using β-type titanium alloy ingot as raw material, free forging at 1100℃~1170℃ into rods of Ф120~Ф150mm, and then removing scale and forging cracks by centerless lathe;

[0024] Step 2: Precisely forge the bar prepared in step 1 into a bar of Ф40-Ф60 mm, use a centerless lathe to remove the scale on the surface, and use a grinder to grind the surface cracks;

[0025] Step 3: Roll the bar prepared in step 2 into a bar of Ф8-Ф9mm, use a centerless lathe to remove the scale on the surface, and use a grinder to grind the surface cracks;

[0026] Step 4: Continuously heat the surface-treated rod in step 3 in a tube furnace at 700°C to 720°C at a speed of 13 to 15m / min to form an oxide layer...

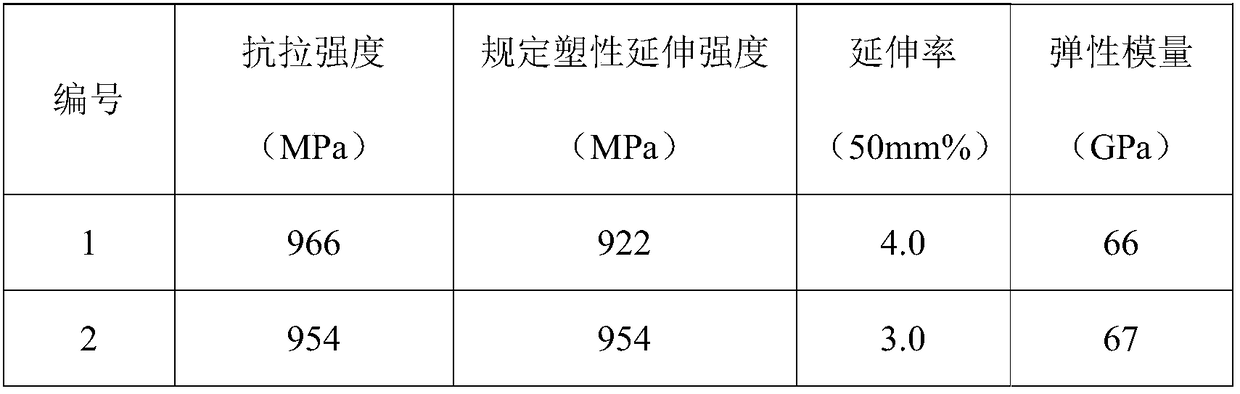

Embodiment 1

[0032] Taking the preparation of Φ3.0mmβ-type titanium alloy welding wire as an example, the preparation steps are as follows:

[0033] Step 1: A β-type titanium alloy ingot is used as a raw material, and the billet is forged at 1170°C, and the finished product is forged at 800°C to make a Ф130mm bar, and then the scale is removed by a centerless lathe to remove forging cracks.

[0034] Step 2: Precision forging the bar prepared in step 1 into a Ф50mm bar by precision forging, using a centerless lathe to remove the scale on the surface, and using a grinder to grind surface cracks.

[0035] Step 3: The bar prepared in step 2 is rolled into a Ф8.5mm bar by rolling, the scale on the surface is removed by using a centerless lathe, and the surface cracks are ground by a grinder.

[0036] Step 4: Continuously heat the surface-treated bar in step 3 in a tube furnace at 700°C and a speed of 13m / min to form an oxide layer, and when the bar comes out of the furnace, it is equipped with ...

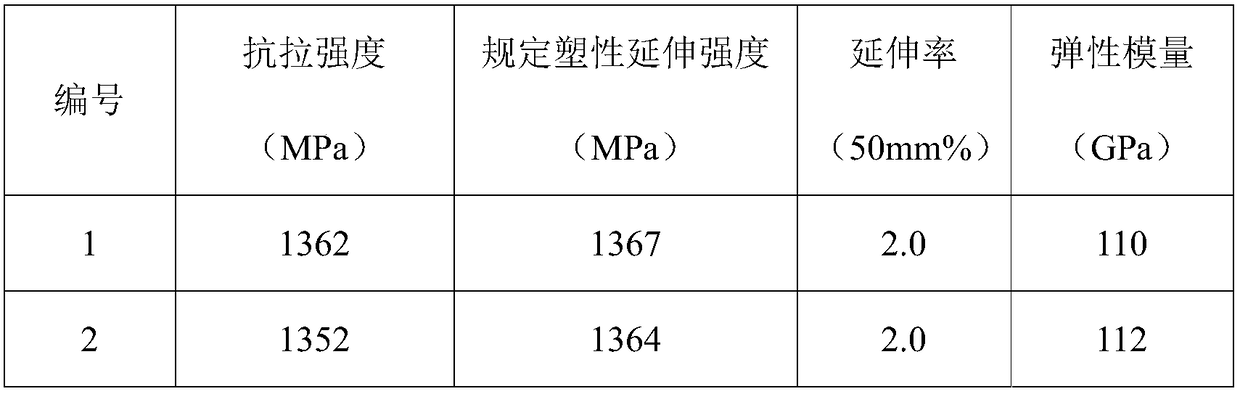

Embodiment 2

[0047] Taking the preparation of Φ2.0mmβ-type titanium alloy welding wire as an example, the preparation steps are as follows:

[0048] Step 1: A β-type titanium alloy ingot is used as a raw material, through free forging at 1150°C, and the billet is made into a Ф130mm bar at 810°C, and then the scale is removed by a centerless lathe to remove forging cracks.

[0049] Step 2: Precision forging the bar prepared in step 1 into a Ф50mm bar by precision forging, using a centerless lathe to remove the scale on the surface, and using a grinder to grind surface cracks.

[0050] Step 3: The bar prepared in step 2 is rolled into a Ф8.5mm bar by rolling, the scale on the surface is removed by using a centerless lathe, and the surface cracks are ground by a grinder.

[0051] Step 4: Continuously heat the surface-treated bar in step 3 in a tube furnace at 710°C and a speed of 14m / min to form an oxide layer, and when the bar comes out of the furnace, it is equipped with a drawing machine w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com