Preparation method of bidirectional bullet-proof glass

A technology of bulletproof glass and glass, which is applied in the direction of protective equipment, chemical instruments and methods, glass/slag layered products, etc. It can solve the problems of hindering penetration of the inner layer of glass, narrow applicable range, and increasing the weight of automobiles, etc., to achieve Effects of preventing glass splashes, preventing secondary damage, and reducing production and development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

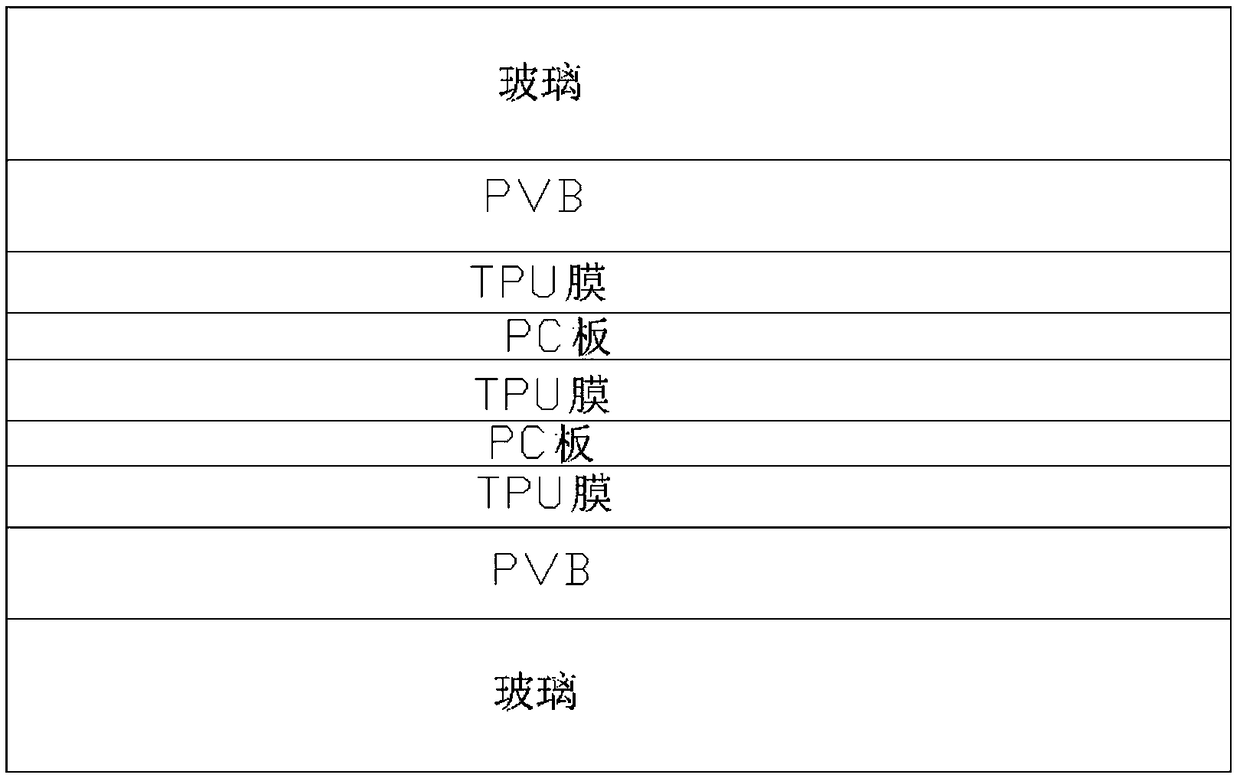

[0030] figure 1 A two-way bulletproof glass of the present invention is schematically shown. Such as figure 1 As shown, the two-way bulletproof glass includes: a first glass sheet, a first PVB film attached to the first glass sheet, a first TPU film attached to the PVB film, and a first TPU film attached to the TPU film. The first thermoplastic resin sheet, the first TPU film attached to the thermoplastic resin sheet, the second thermoplastic resin sheet attached to the first TPU film, attached to the second thermoplastic resin sheet The second TPU film, the second PVB film attached to the second TPU film, and the second glass sheet attached to the second PVB film.

[0031] A preparation method of bulletproof glass, comprising the steps of:

[0032] Raw material preparation

[0033] a: The original glass sheet is cut, edged, clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com