Modified aluminate cement retarder as well as preparation method and application thereof

A technology of aluminate cement and setting retarder, applied in the field of cement retardation, can solve the problems affecting the effect of retarder and the performance of modified aluminate cement, achieve cost controllable, improve right-angle thickening performance, The effect of improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for preparing a modified aluminate cement retarder, which specifically includes the following steps:

[0042] X1. Raw material mixing

[0043] Put AMPS, unsaturated carboxylic acid, boric acid and glucose into the reactor according to the mass percentage, add deionized water and stir evenly, the stirring speed is 120r / min, and the temperature is raised to 60-75°C.

[0044] X2. Exhaust air

[0045] Exhaust the air and then pass in an inert gas to remove the air; the inert gas is a stable gas, not an inert gas in a narrow sense, and can be nitrogen or argon.

[0046] X3. Trigger

[0047] Add the initiator into the reaction kettle, and obtain the retarder after reacting for 3-4 hours. The initiator is sodium hydroxide, ammonium persulfate or potassium persulfate.

[0048]In this patent, the boric acid and the carboxyl group in the unsaturated carboxylic acid form a good synergistic effect, that is, the boric acid and the carboxyl group...

Embodiment 2~ Embodiment 4

[0050] Prepare the modified aluminate cement retarder according to the ratio shown in the following table: Weigh AMPS, unsaturated hydroxy acid, boric acid and glucose respectively, put the raw materials into the reactor, add deionized water and stir evenly, heat up to The reaction temperature is 60-75°C, and then nitrogen is introduced to remove the air, and the initiator sodium hydroxide, ammonium persulfate or potassium persulfate is added, and the retarder is obtained after 3-4 hours of reaction, which is then purified, dried and crushed for later use. As shown in Table 1:

[0051]

[0052] Table 1

[0053] Aluminate cement was prepared, and the setting retarders in Examples 2 to 4 were added respectively, and the properties were compared. As follows:

[0054] According to the component design of Example 4 in the patent 201610984589.2 "A Modified Aluminate Cement", 68wt% of aluminate cement, 10wt% of sodium hexametaphosphate, 12wt% of micro silicon and 10wt% of slag w...

Embodiment 3

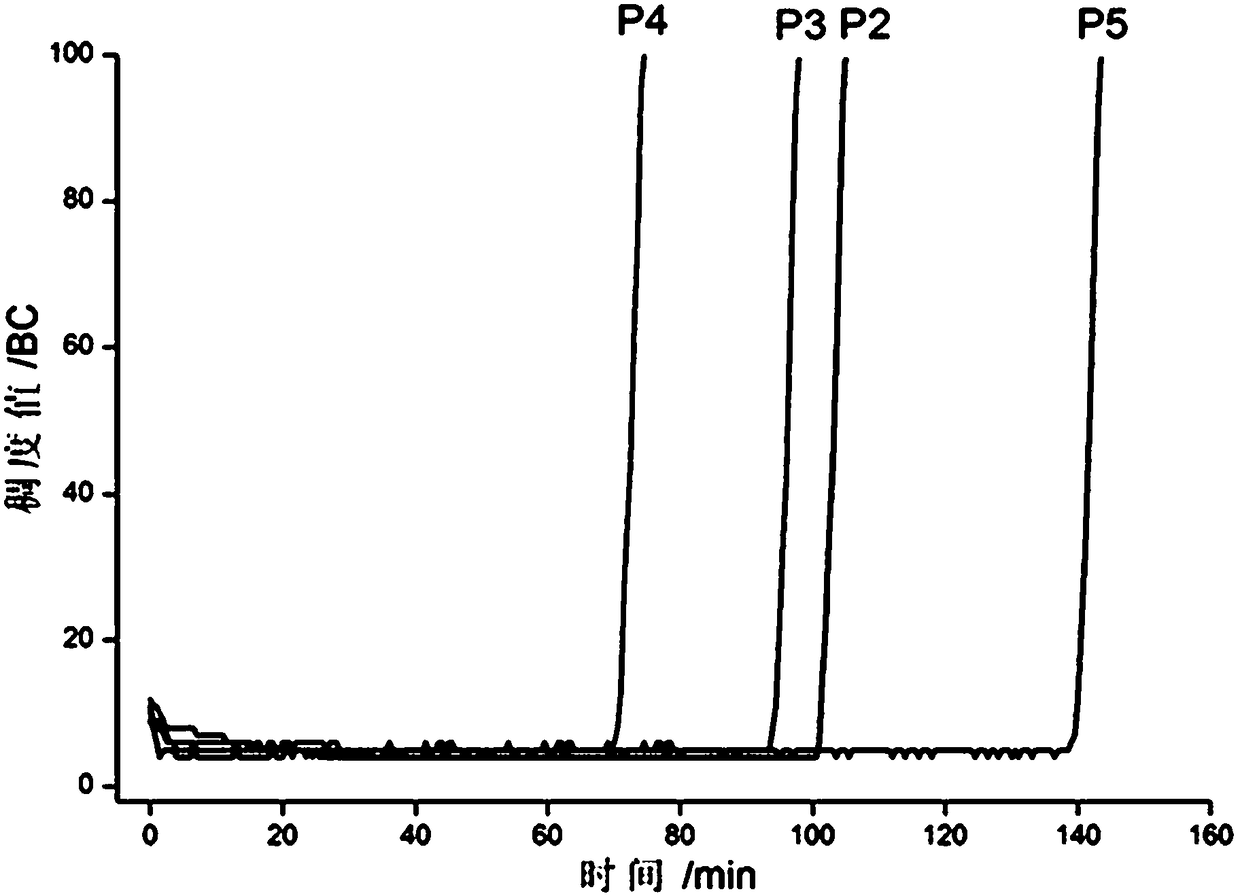

[0071] Both the setting retarder of Example 3 and the setting retarder of Example 4 can also effectively control the setting time of the modified aluminate cement.

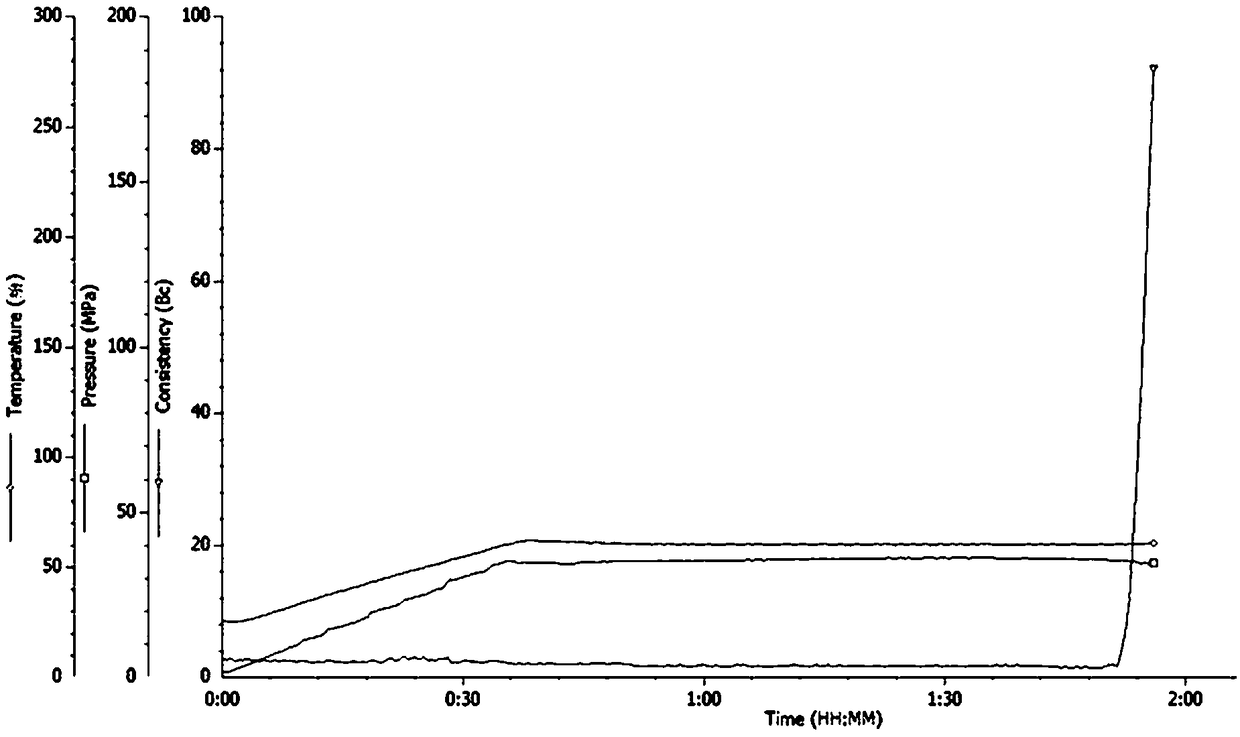

[0072] When the content of the retarder in Example 3 changes, the thickening time changes accordingly, showing an effective control state, and the thickening curves all have obvious right-angle thickening phenomenon.

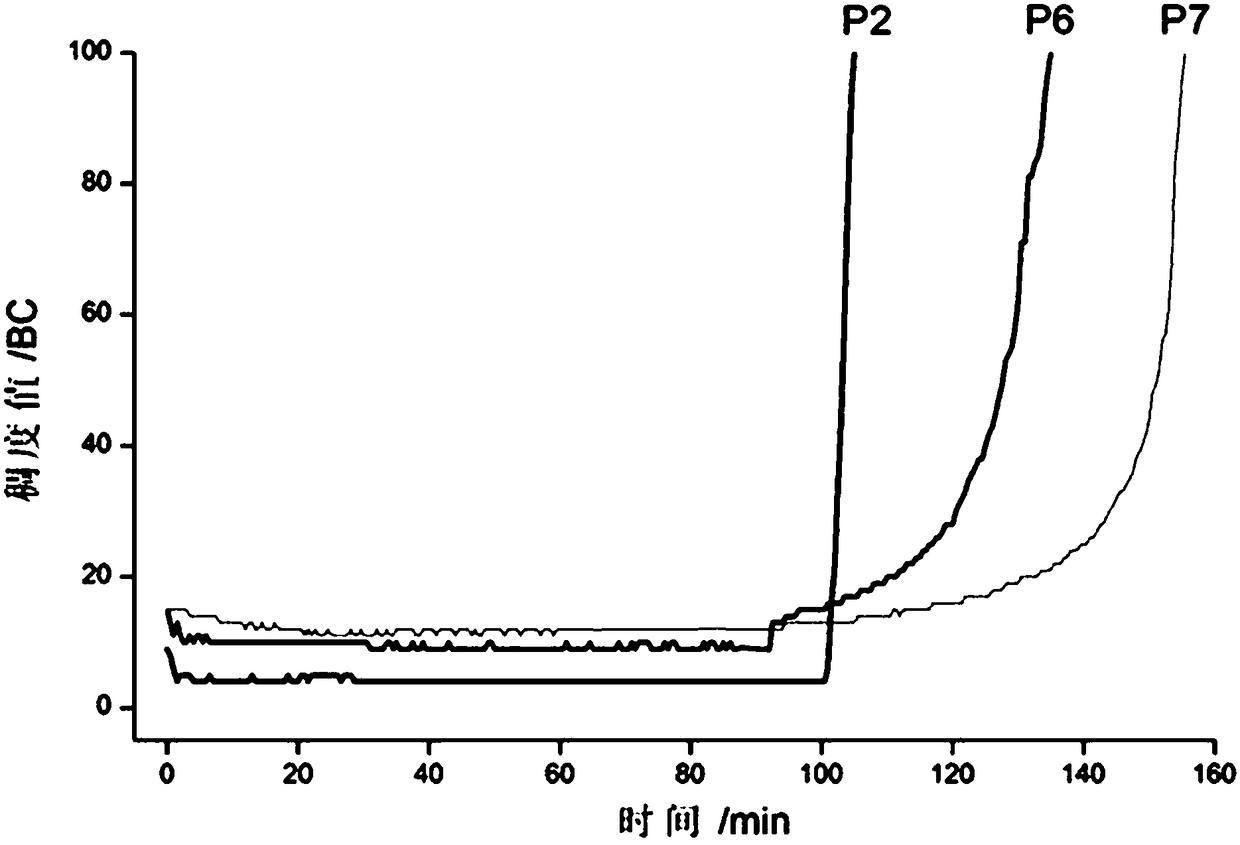

[0073] image 3 It is the comparison chart of thickening time of P2, P6 and P7.

[0074] When mixed with 5% or 10% G-grade high-resistance oil well cement, the thickening time is prolonged and the right-angle characteristic of the thickening curve disappears, but it can still effectively meet the requirements of cementing construction, which shows that the retarder can effectively meet the requirements of the improved oil well cement. It has good ability to resist Portland cement pollution.

[0075] Figure 4 It is a comparison chart of compressive strength values of P0-P8 cured at 60°C for 1 d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com