Magnetorheological gel and preparation method thereof

A magnetorheological and magnetic fluid technology, applied in the field of magnetorheology, can solve the problems of reducing density, inability to disperse particles, and large density of particles and carrier liquid, so as to enhance magnetorheological effect, improve settlement stability, and improve mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

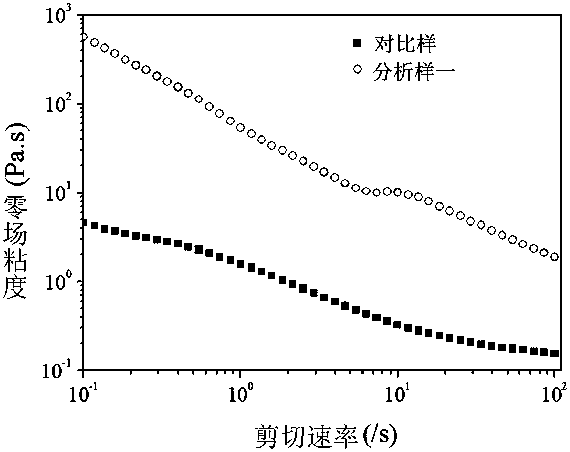

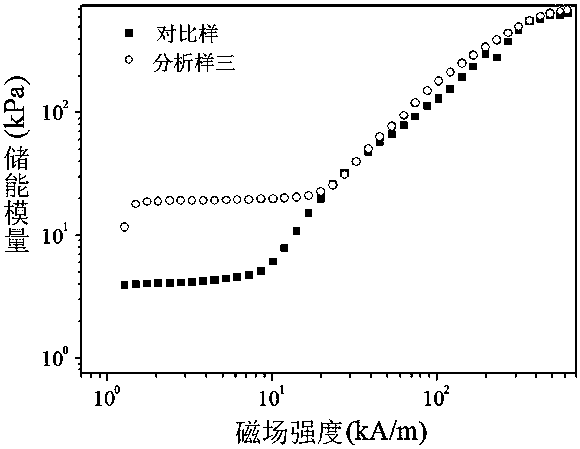

Embodiment 1

[0031] Embodiment 1, a magnetorheological glue, including magnetic particles, carrier liquid and a polar solvent immiscible with the carrier liquid; the magnetic particles, carrier liquid and polar solvent are composed of the following volume percentages:

[0032] Magnetic particles: 10~40%,

[0033] Carrier liquid: 60~90%,

[0034] Polar solvent: 0.1~10%.

[0035] The magnetic particles are carbonyl iron powder, the average particle size of the carbonyl iron powder is 1-10 μm; the carrier liquid is mineral oil, silicone oil or polyalphaolefin; the polar solvent is deionized water, ethylene glycol , glycerol, dichloromethane, polyethylene glycol in one or more combinations.

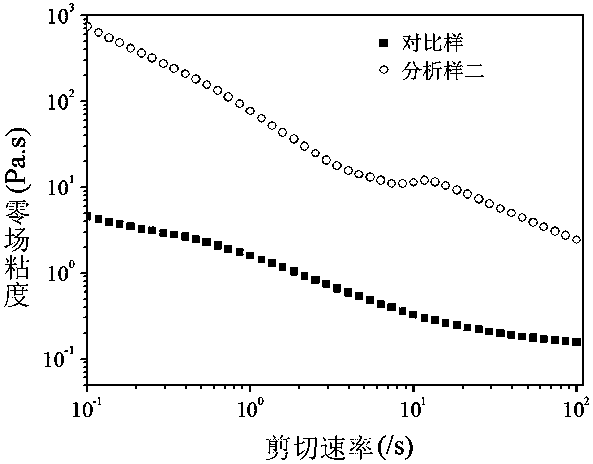

Embodiment 2

[0036] Embodiment 2, a magnetorheological glue, including magnetic particles, carrier liquid and magnetic fluid immiscible with the carrier liquid; the magnetic particles, carrier liquid and magnetic fluid are composed according to the following volume percentage:

[0037] Magnetic particles: 10~40%,

[0038] Carrier liquid: 60~90%,

[0039] Ferrofluid: 0.1~10%.

[0040] The magnetic particles are carbonyl iron powder, and the average particle size of the carbonyl iron powder is 1-10 μm; the carrier liquid is mineral oil, silicone oil or polyalphaolefin; the magnetic fluid includes deionized water and ultrasonic dispersion in the The magnetic particle g-Fe with a particle size of 3-15 nm in deionized water 2 o 3 or Fe 3 o 4 , the magnetic particles g-Fe 2 o 3 or Fe 3 o 4 The volume percentage in the magnetic fluid is 0.1~2%.

Embodiment 3

[0041] Embodiment three, a kind of preparation method of magnetorheological glue, it comprises the following steps:

[0042] 1) Take 12.48g of carbonyl iron powder and dry it for 12 hours under the condition of vacuum degree of 0.1MPa and temperature of 80°C to remove the physically adsorbed water on the surface of carbonyl iron powder;

[0043] 2) Take an appropriate amount of ethylene glycol and add it to 6.27mL of mineral oil, stir it evenly, and then ultrasonically break it for 5 minutes to obtain a mixed solution;

[0044] 3) Add the dried carbonyl iron powder to the mixed liquid obtained in step 2), stir evenly, and then ultrasonically disperse for 5 minutes to obtain a suspension gel;

[0045] 4) Place the suspension glue obtained in step 3) in a vacuum drying oven to remove air bubbles. Under the conditions of a vacuum of 0.2 MPa and a temperature of 25°C, remove air bubbles for 10 minutes to obtain a magnetorheological glue. The composition of the glue is: carbonyl i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com