Preparation method of composite FNM (fluorescent nanofiber membrane)

A technology of fluorescent nanofibers and nanofiber membranes, applied in fiber treatment, textiles, papermaking, nonwovens, etc., can solve the problems of complex preparation methods, time-consuming purification process, high toxicity, etc., and achieve simple preparation methods and excellent stability The effect of high stability, excellent color rendering and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

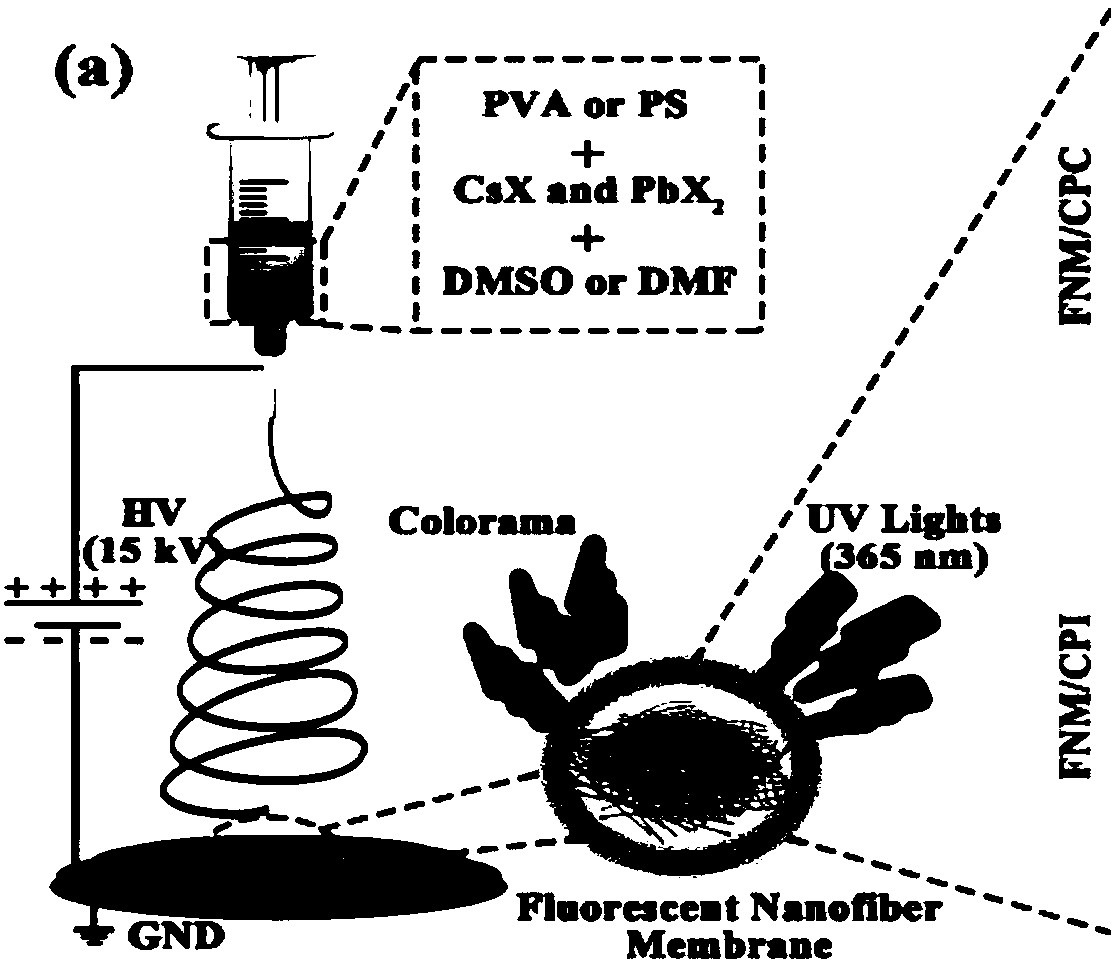

[0036] A method for preparing a composite fluorescent nanofiber film, said method comprising the steps of:

[0037] 1) Preparation of precursor solution: first 0.184g PbCl 2 Add 10ml of dimethylformyl to PbCl 2 After the complete dissolution, continue to add 0.104g CsI, and then add 0.2g polystyrene after the CsCl is completely dissolved to obtain the spinning precursor solution;

[0038]2) Preparation of nanofibrous membrane by polymer electrospinning: place the precursor solution in step 1) in a syringe pump, place copper foil 10 cm below the injection needle, and apply a voltage of 10 kV between the copper foil and the injection needle, Push the syringe pump at a constant speed of 0.67ml / h to obtain a nanofiber membrane on the copper foil, and separate the nanofiber membrane from the substrate to obtain the composite fluorescent nanofiber membrane FNM / CPC.

Embodiment 2

[0040] A method for preparing a composite fluorescent nanofiber film, said method comprising the steps of:

[0041] 1) Preparation of precursor solution: first 0.184g PbBr 2 Add 10ml of dimethylformyl to PbBr 2 After the complete dissolution, continue to add 0.104g CsBr, and then add 0.2g polystyrene after the CsBr is completely dissolved to obtain the spinning precursor solution;

[0042] 2) Preparation of nanofibrous membrane by polymer electrospinning: place the precursor solution in step 1) in a syringe pump, place copper foil 10 cm below the injection needle, and apply a voltage of 10 kV between the copper foil and the injection needle, Push the syringe pump at a constant speed of 0.67ml / h to obtain a nanofiber membrane on the copper foil, and separate the nanofiber membrane from the substrate to obtain the composite fluorescent nanofiber membrane FNM / CPB.

Embodiment 3

[0044] A method for preparing a composite fluorescent nanofiber film, said method comprising the steps of:

[0045] 1) Preparation of precursor solution: first, 0.184g PbI 2 Add 10ml dimethyl sulfoxide, wait for PbI 2 After complete dissolution, continue to add 0.104g CsI, and then add 0.2g polyvinyl alcohol after CsI is completely dissolved to obtain the spinning precursor solution;

[0046] 2) Preparation of nanofibrous membrane by polymer electrospinning: place the precursor solution in step 1) in a syringe pump, place copper foil 10 cm below the injection needle, and apply a voltage of 10 kV between the copper foil and the injection needle, Push the syringe pump at a constant speed of 0.67ml / h to obtain a nanofiber membrane on the copper foil, and separate the nanofiber membrane from the substrate to obtain the composite fluorescent nanofiber membrane FNM / CPI.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com