Natural gas leakage warning monitoring apparatus and method based on optic-fiber FP cavity-type probe

A monitoring device and natural gas technology, which is applied in the measurement of color/spectral characteristics, etc., can solve the problems of increased detection time, unsuitability, and measurement distance of less than 10m, and achieves a high-accuracy detection effect with sufficient laser energy, easy installation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The sensor group 6 adopts 5 groups of sensors arranged in parallel and located at 5 positions respectively.

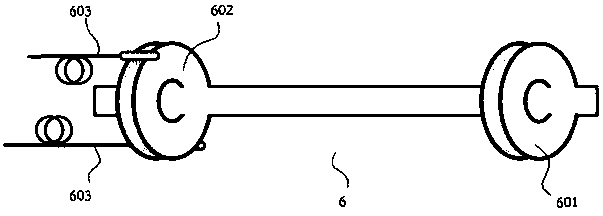

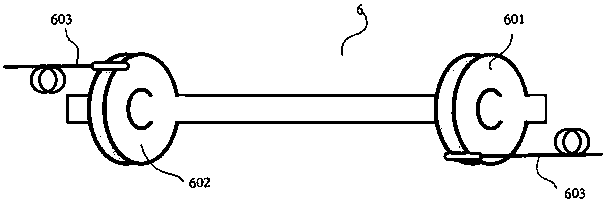

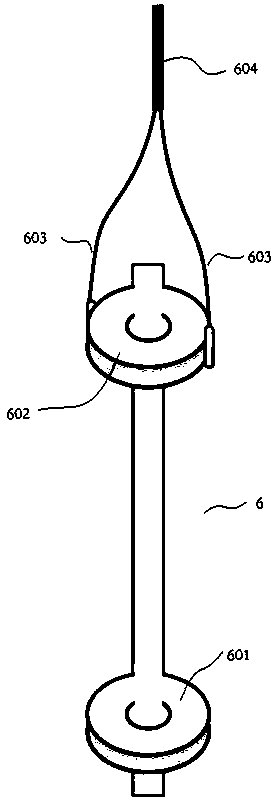

[0049] Among them such as Figure 8 As shown, the sensor group 6 adopts a FP cavity probe sensor; the FP cavity probe includes an armored optical cable 604, a first mirror 601 and a second mirror 602; as Figure 11 As shown, in the process of use, in order to ensure the tensile capacity and mechanical properties of the optical cable, it is necessary to use an armored optical cable. During processing, the armored optical cable is directly connected to the incident end and the outgoing end. The armored optical cable 604 includes a group of optical fibers 603; one optical fiber 603 is connected to the first mirror 601, and the other optical fiber 603 is connected to the second mirror 602; a group of optical fibers 603 are incident ends and output ends respectively.

[0050] Among them such as image 3 As shown, the laser processing system includes a beam splitte...

Embodiment 2

[0058] The sensor group 6 adopts 5 groups of sensors arranged in parallel and located at 5 positions respectively.

[0059] Among them such as Figure 8 As shown, sensor group 6 adopts FP cavity probe sensor; FP cavity probe includes armored optical cable 604, first mirror 601 and second mirror 602; Armored fiber optic cable is used. During processing, the armored optical cable is directly connected to the incident end and the outgoing end. The armored optical cable 604 includes a group of optical fibers 603; the group of optical fibers 603 are all connected to the second mirror 602; the group of optical fibers 603 are incident ends and output ends respectively.

[0060] Among them such as figure 2 As shown, the laser processing system includes an optical switch 11; the laser 3 transmits the laser light to the optical switch 11 through a circulator 5, and the optical switch 11 allows the laser light to pass through the sensors of five measuring positions in a time-sharing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com