Preparation method of Bi-2212 multi-core superconducting wire

A bi-2212, superconducting wire technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems of high technical content, complicated operation, expensive high-pressure heat treatment equipment, etc. Improve the preparation efficiency, increase the contact area, and avoid the effect of performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment includes the following steps:

[0035] Step 1. The Bi-2212 powder prepared by the improved co-precipitation method was subjected to high-temperature sintering three times to obtain Bi-2212 tube-packed precursor powder 1; the temperature of the high-temperature sintering was 850°C for 20 hours;

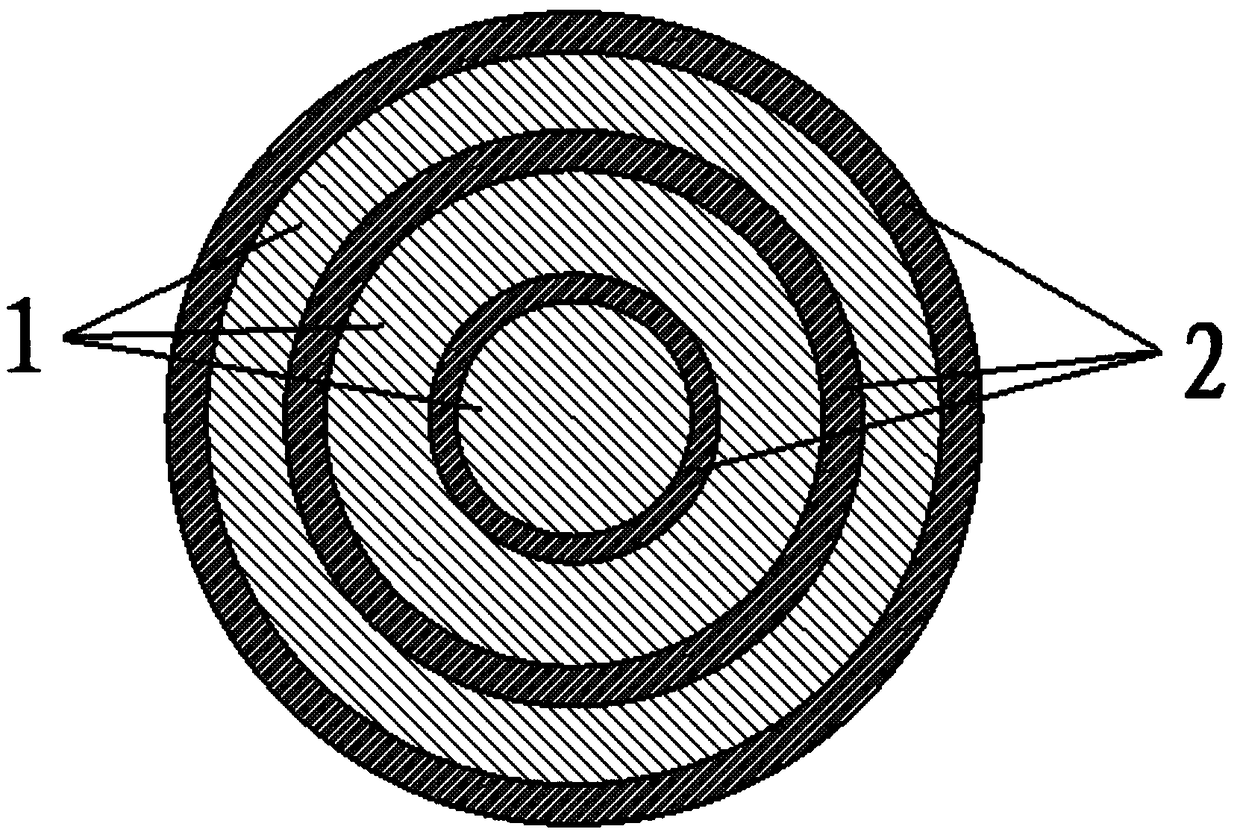

[0036] Step 2, use a vibrating table in a glove box in a vacuum state to vibrate the tube under the condition that the vibration frequency is 40 Hz, and put the Bi-2212 tube-loading precursor powder 1 obtained in step 1 into the gap of the silver sleeve 2 to obtain The first tube-loading complex; the vacuum in the glove box is not more than 100Pa; the silver sleeve 2 is formed by stacking silver tubes whose centerlines overlap, such as figure 1 Shown, wherein the diameter of outer layer silver tube is 21mm, and wall thickness is 1mm, and the diameter of middle layer silver tube is 14mm, and wall thickness is 1mm, and the diameter of inner layer silver tube is 7mm...

Embodiment 2

[0046] Step 1. The Bi-2212 powder prepared by the improved co-precipitation method was subjected to high-temperature sintering three times to obtain Bi-2212 tube-packed precursor powder 1; the temperature of the high-temperature sintering was 840°C for 18 hours;

[0047] Step 2, use a vibrating table in a glove box in a vacuum state to vibrate the tube under the condition that the vibration frequency is 40 Hz, and put the Bi-2212 tube-loading precursor powder 1 obtained in step 1 into the gap of the silver sleeve 2 to obtain The first tube-loading complex; the vacuum in the glove box is not more than 100Pa; the silver sleeve 2 is formed by stacking silver tubes whose centerlines overlap, such as figure 1 Shown, wherein the diameter of outer layer silver tube is 28mm, and wall thickness is 1.5mm, and the diameter of middle layer silver tube is 19mm, and wall thickness is 1.2mm, and the diameter of inner layer silver tube is 10mm, and wall thickness is 1.2mm; The position of eac...

Embodiment 3

[0057] Step 1. The Bi-2212 powder prepared by the improved co-precipitation method is subjected to high-temperature sintering twice to obtain Bi-2212 tube-packed precursor powder 1; the temperature of the high-temperature sintering is 850° C., and the time is 18 hours;

[0058] Step 2, use a vibrating table in a glove box in a vacuum state to vibrate the tube under the condition that the vibration frequency is 40 Hz, and put the Bi-2212 tube-loading precursor powder 1 obtained in step 1 into the gap of the silver sleeve 2 to obtain The first tube-loading complex; the vacuum in the glove box is not more than 100Pa; the silver sleeve 2 is formed by stacking silver tubes whose centerlines overlap, such as figure 1 Shown, wherein the diameter of outer layer silver tube is 25mm, and wall thickness is 1.2mm, and the diameter of middle layer silver tube is 17mm, and wall thickness is 1.1mm, and the diameter of inner layer silver tube is 8.5mm, and wall thickness is 1.1mm; Fix the pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap