A cross-linked fluorescent display and its preparation method and application

A display screen and cross-linking technology, which is applied in the direction of image/graphic display tubes, discharge tubes, screen tubes, etc., can solve the problems of OLED technology threshold and high investment, micro-display challenges, and high prices. Effects of suppression of color purity decline, simple preparation method, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a cross-linked fluorescent display screen and a preparation method thereof.

[0058] A cross-linked fluorescent display:

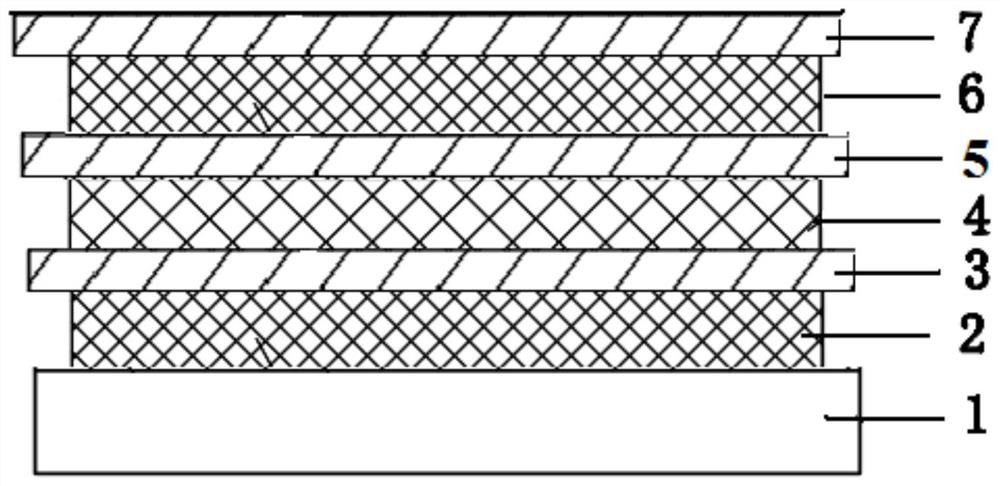

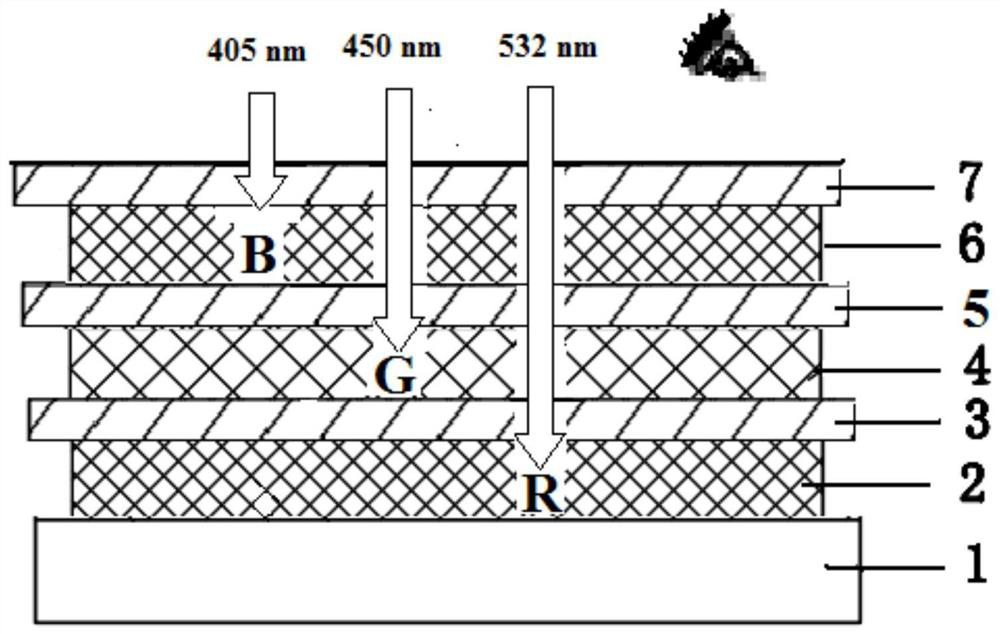

[0059] Such as figure 1 As shown, the cross-linked fluorescent display screen in this embodiment consists of a substrate (1), a red fluorescent material layer (2), a first isolation layer (3), a green fluorescent material layer (4), a second isolation layer (5 ), the blue fluorescent material layer (6) and the protective layer (7) are sequentially laminated.

[0060] The substrate is made of glass;

[0061] The structural formula of the material of the red fluorescent material layer is as follows:

[0062]

[0063] The structural formula of the material of the green fluorescent material layer is as follows:

[0064]

[0065] The structural formula of the material of the blue fluorescent material layer is as follows:

[0066]

[0067] The material of the first isolation layer and the second isolation layer is po...

Embodiment 2

[0074] This embodiment provides a cross-linked fluorescent display screen and a preparation method thereof.

[0075] The structure and preparation method of the cross-linked fluorescent display screen in this embodiment are the same as those in Embodiment 1, except that the fluorescent materials, especially the cross-linking groups, and the cross-linking process are different.

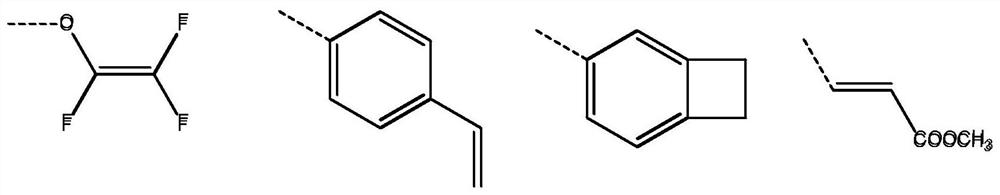

[0076] The structural formula of the material of the red fluorescent material layer is as follows:

[0077]

[0078] The structural formula of the material of the green fluorescent material layer is as follows:

[0079]

[0080] The structural formula of the material of the blue fluorescent material layer is as follows:

[0081]

[0082] The preparation method of the above-mentioned cross-linked fluorescent display screen:

[0083] The red fluorescent material was dissolved in toluene to make a red fluorescent toluene solution with a concentration of 2wt.%, spin-coated on a glass substrate f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com