Composite material for lithium-sulfur battery positive electrode and preparation method of composite material

A technology of lithium-sulfur batteries and composite materials, which is applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problem of weak binding force of sulfur or lithium polysulfide, and achieve the inhibition of shuttle effect, improvement of synthesis efficiency, and mitigation of the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

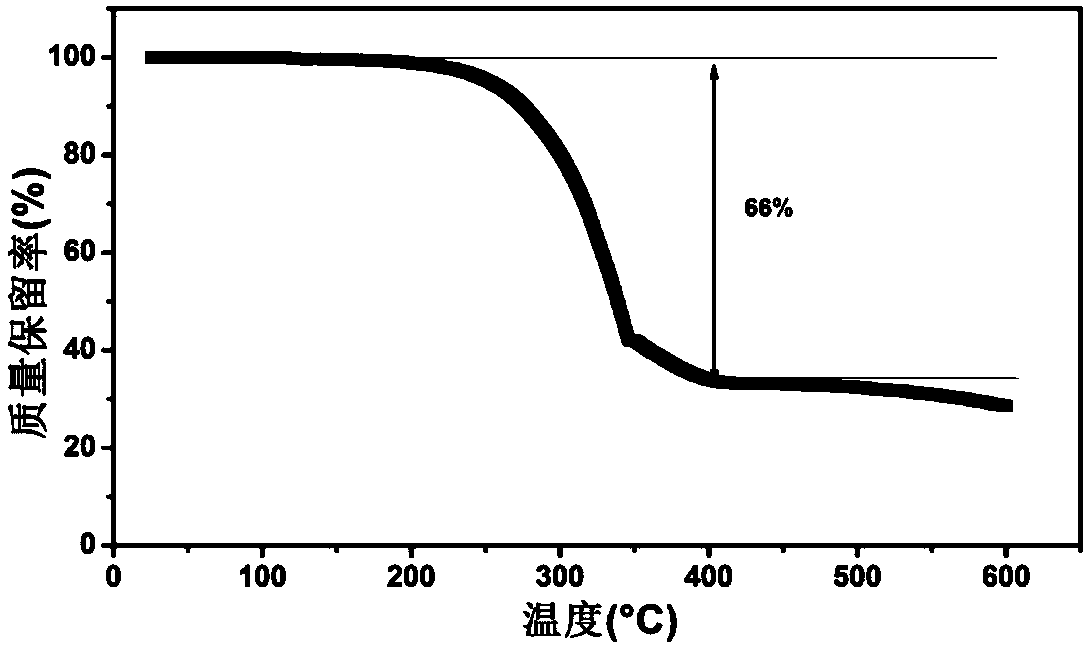

[0023] specific implementation

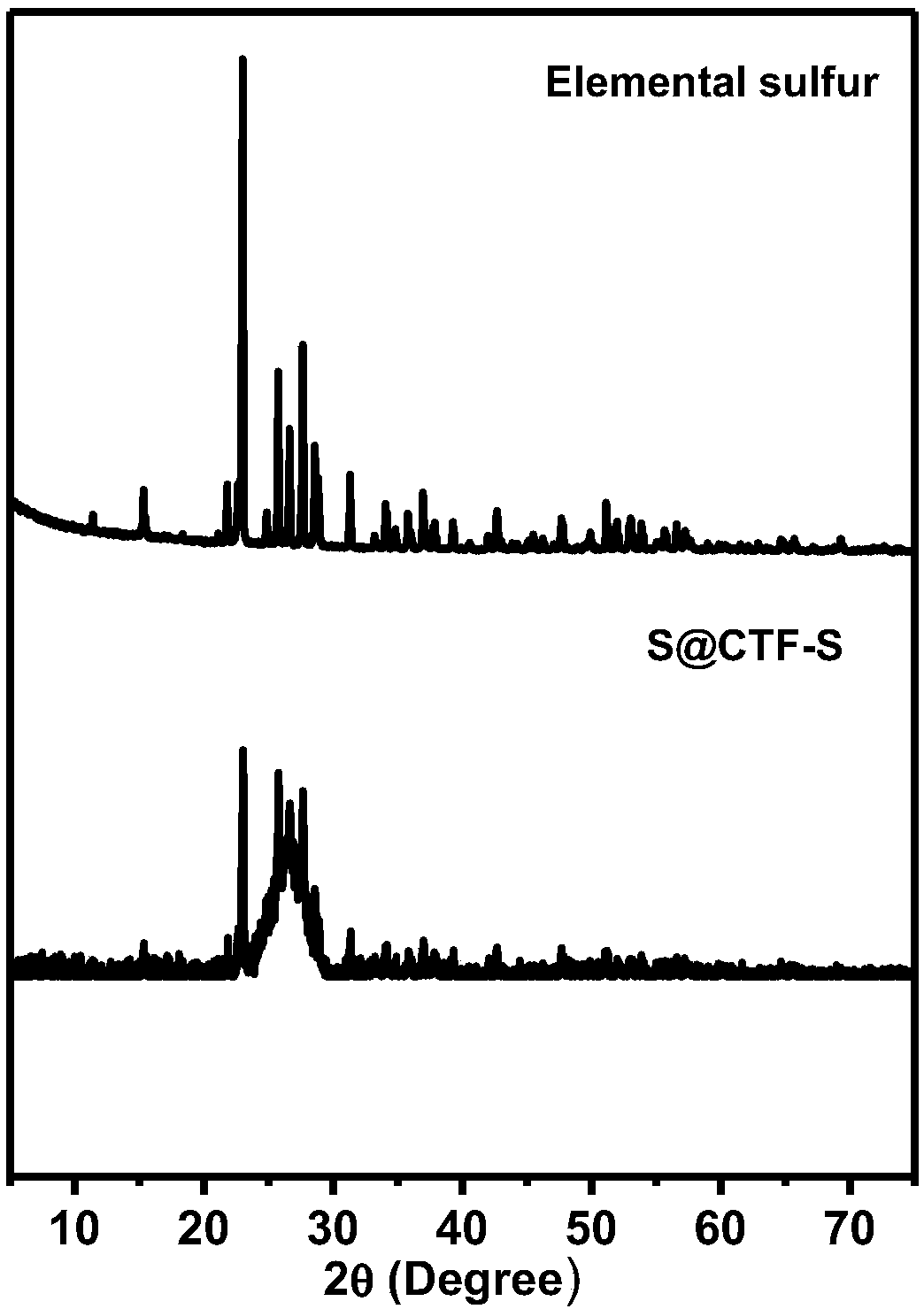

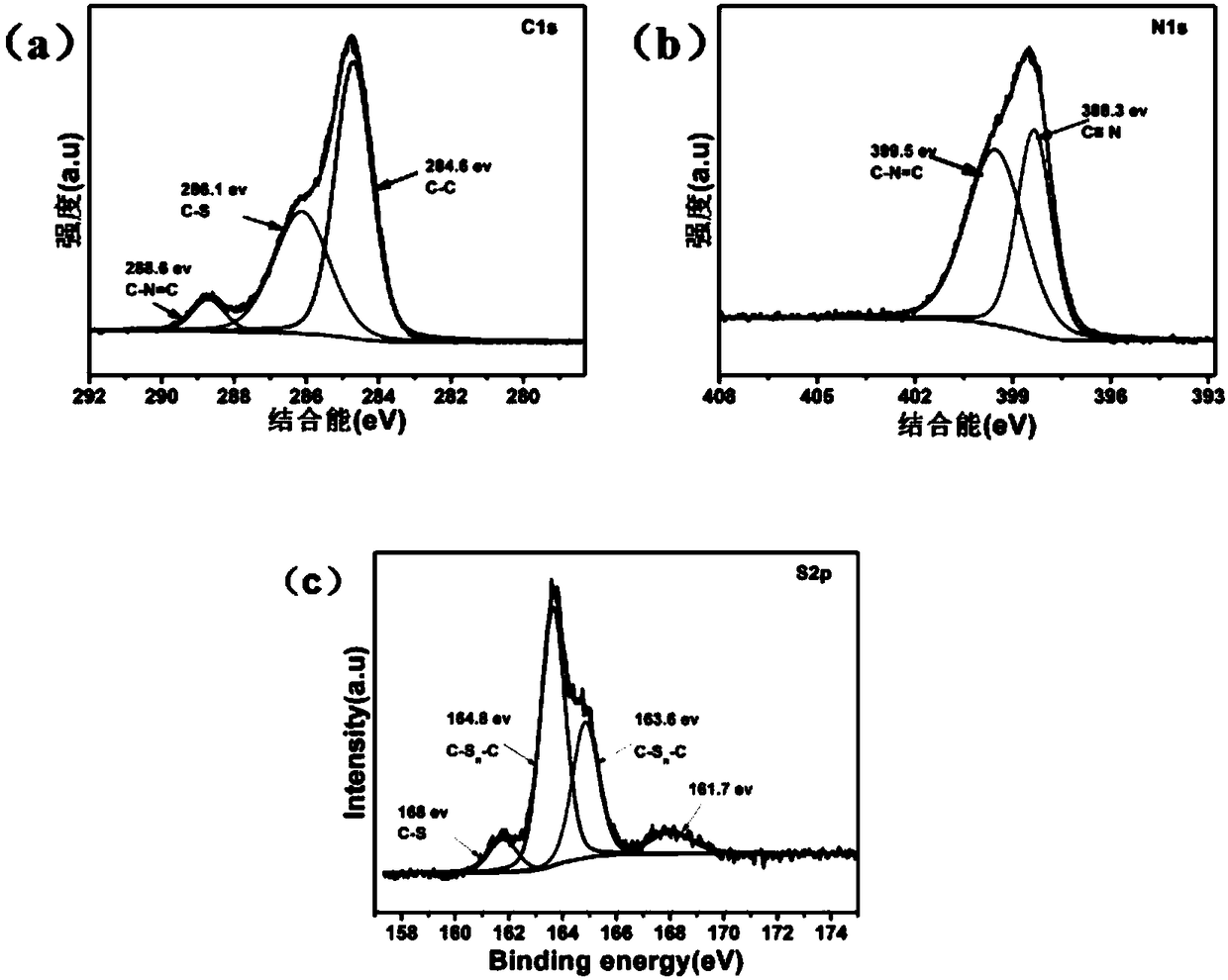

[0024] (1) Dissolve 3.5g sublimated sulfur in 7.6g CS 2 , ultrasonically disperse for 5 min; then add 5.4 g of diaminomaleonitrile, and ultrasonically disperse for 30 min; then put the mixture into an autoclave, repeatedly evacuate and replenish nitrogen for three times, seal it, and heat at 400°C for 12 h; Grind it evenly with sublimed sulfur at a mass ratio of 40:60, put it into a glass tube, and vacuum seal it; put the glass tube into a tube furnace and heat it at 155°C for 12h, and then heat it up to 200°C for 30min. Finally, the composite material S@CTF-S was prepared. The same method as above was used to prepare 66% sulfur content without adding sublimed sulfur presulfurization and without adding sublimed sulfur with CS 2 Prevulcanized composite materials, respectively marked CS 2 -CTF-S and CTF-S.

[0025] (2) Weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com