Chewable tablet rich in green tea dietary fibers and preparation method thereof

A technology of dietary fiber and dietary fiber powder, which is applied in the field of food processing to achieve smooth taste, good market prospects, and the effect of expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

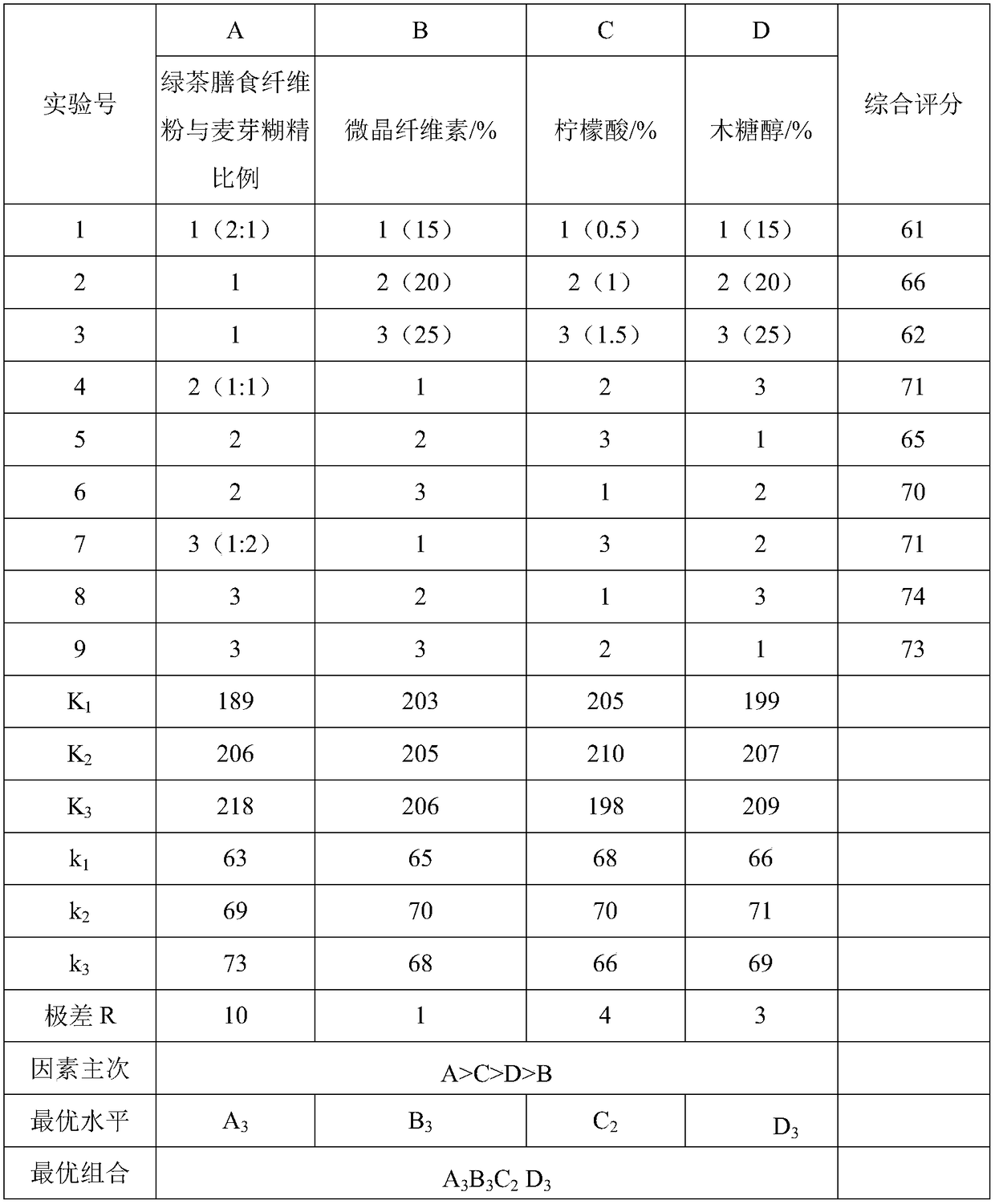

Examples

Embodiment 1

[0029] A preparation method of chewable tablets rich in green tea dietary fiber, comprising the following steps:

[0030] (1) Grind the green tea leaves, sieve them through a 40-mesh sieve, place them in a blast drying oven, and dry them at 105°C for 5 hours; accurately weigh a certain amount of dried green tea, and add distilled water at a ratio of 1g to 35mL of material to liquid, After stirring evenly, ultrasonically extract at 70°C and 175W power for 60min, after cooling, centrifuge at 6000r / min for 10min, take the tea dregs, dry at 60°C overnight to obtain green tea dregs dietary fiber.

[0031] (2) According to 50g: crush the green tea dietary fiber, pass through a 40-mesh sieve, and bake at 105°C for 5h; add 50% distilled water to the green tea dietary fiber, stir evenly, let stand for 1h, and at a temperature of 110°C, screw Extrusion modification treatment under the condition of rotating speed of 540r / min, drying at 65°C, crushing and passing through a 40-mesh sieve t...

Embodiment 2

[0034] A preparation method of chewable tablets rich in green tea dietary fiber, comprising the following steps:

[0035] (1) Grind the green tea leaves, sieve them through a 40-mesh sieve, place them in a blast drying oven, and dry them at 105°C for 5 hours; accurately weigh a certain amount of dried green tea, and add distilled water at a ratio of 1g to liquid: 35mL. After stirring evenly, ultrasonically extract at 70°C and 175W power for 60min, after cooling, centrifuge at 6000r / min for 10min, take tea dregs, and dry at 60°C overnight to obtain green tea dregs dietary fiber.

[0036] (2) According to 50g: crush the green tea dietary fiber, pass through a 60-mesh sieve, and bake at 105°C for 5 hours; add 60% distilled water to the green tea dietary fiber, stir evenly, let stand for 1.5h, and at a temperature of 106°C, Extrusion modification treatment under the condition of screw speed of 450r / min, drying at 70°C, crushing and passing through a 60-mesh sieve to obtain primary...

Embodiment 3

[0039] A preparation method of chewable tablets rich in green tea dietary fiber, comprising the following steps:

[0040] (1) Grind the green tea leaves, sieve them through a 40-mesh sieve, place them in a blast drying oven, and dry them at 105°C for 5 hours; accurately weigh a certain amount of dried green tea, and add distilled water at a ratio of 1g to 35mL of material to liquid, After stirring evenly, ultrasonically extract at 70°C and 175W power for 60min, after cooling, centrifuge at 6000r / min for 10min, take the tea dregs, dry at 60°C overnight to obtain green tea dregs dietary fiber.

[0041] (2) According to 50g: crush the green tea dietary fiber, pass through a 100-mesh sieve, and bake at 105°C for 5 hours; add 50% distilled water to the green tea dietary fiber, stir evenly, let it stand for 1 hour, and dry it at a temperature of 100-120°C , Extrusion modification treatment under the condition that the screw speed is 360r / min, drying at 75°C, crushing through a 100-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com