MEMS device, preparation method thereof and electronic device

A technology of electronic devices and devices, which is applied in the field of MEMS devices and its preparation, can solve problems such as easy fracture of the diaphragm edge and sacrifice of microphone performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The present invention also provides a method for preparing a MEMS device, the method comprising:

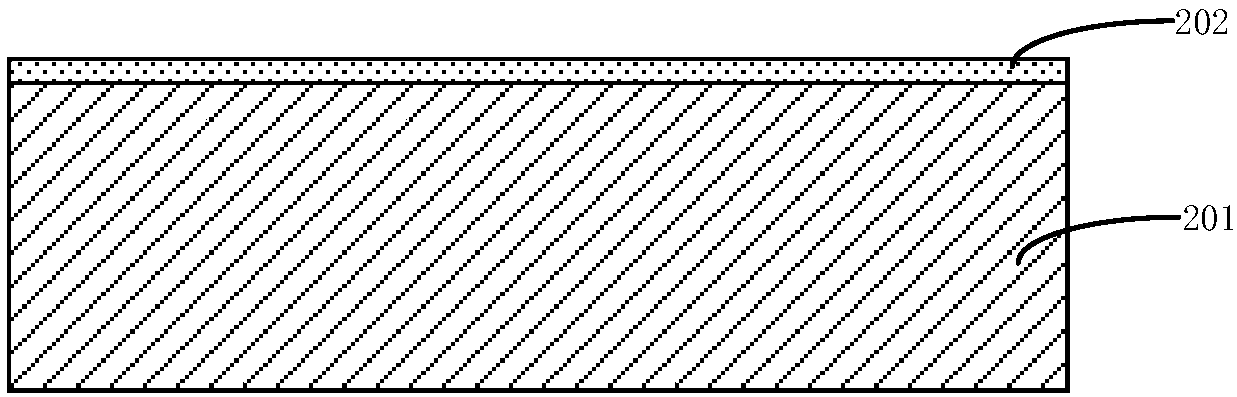

[0069] providing a base 201;

[0070] forming a diaphragm on the substrate, wherein an edge portion of the diaphragm is thicker than a central portion of the diaphragm;

[0071] A back plate 206 is formed above the diaphragm, a cavity is formed between the diaphragm and the back plate, and the central portion and part of the edge portion are exposed in the cavity.

[0072] Wherein, the method for forming the diaphragm includes:

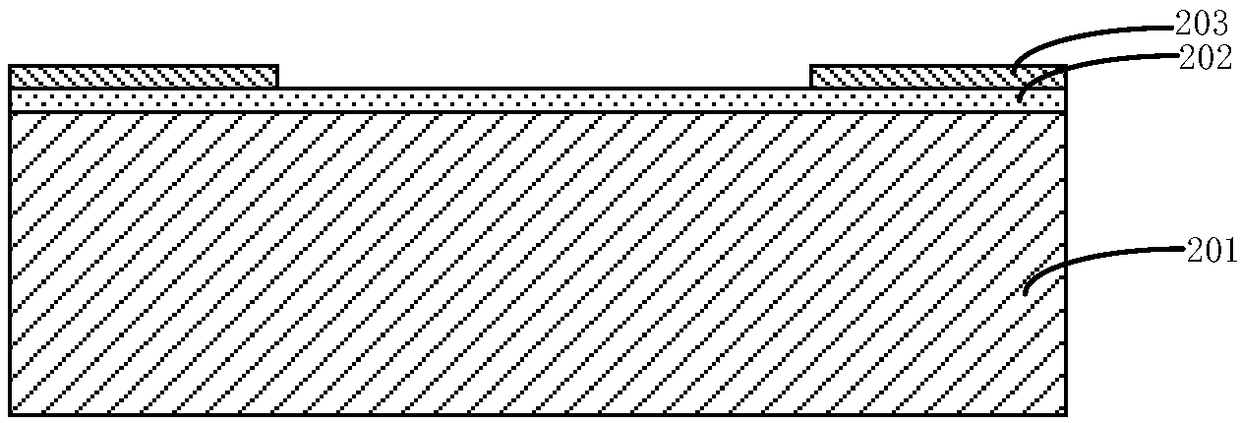

[0073] forming a diaphragm body above the base;

[0074] An auxiliary diaphragm is formed, and the auxiliary diaphragm is stacked with the edge portion of the diaphragm body and fixed together.

[0075] Specifically, the method for forming the auxiliary diaphragm includes:

[0076] forming and patterning an auxiliary diaphragm material on the substrate to remove the auxiliary diaphragm material located in a central region of the diaphragm, the...

Embodiment 1

[0085] The MEMS devices include:

[0086] Base 201;

[0087] a diaphragm located above the base, the thickness of the edge portion of the diaphragm is greater than the thickness of the central portion of the diaphragm;

[0088] a back plate 206, located above the diaphragm;

[0089] A cavity is located between the diaphragm and the back plate, the central part and part of the edge part are exposed in the cavity.

[0090] Wherein, the diaphragm includes:

[0091] The diaphragm body 204 is located above the base;

[0092] The auxiliary diaphragm 203 is stacked with the edge portion of the diaphragm body and fixed together.

[0093] Optionally, the upper and lower positions of the diaphragm body and the auxiliary diaphragm can be set arbitrarily, for example, the diaphragm body is located above the auxiliary diaphragm, or the auxiliary diaphragm is located at the top of the diaphragm body. Above all can realize the purpose of the present invention.

[0094] Such as Figure...

Embodiment 2

[0110] In order to solve the problems in the prior art, the present invention provides a method for manufacturing MEMS devices, which will be further described below in conjunction with the accompanying drawings. in, Figures 2a-2j It is a schematic diagram of the preparation process of the MEMS device described in the present invention; image 3 is an external view of an example of a mobile phone handset in the present invention.

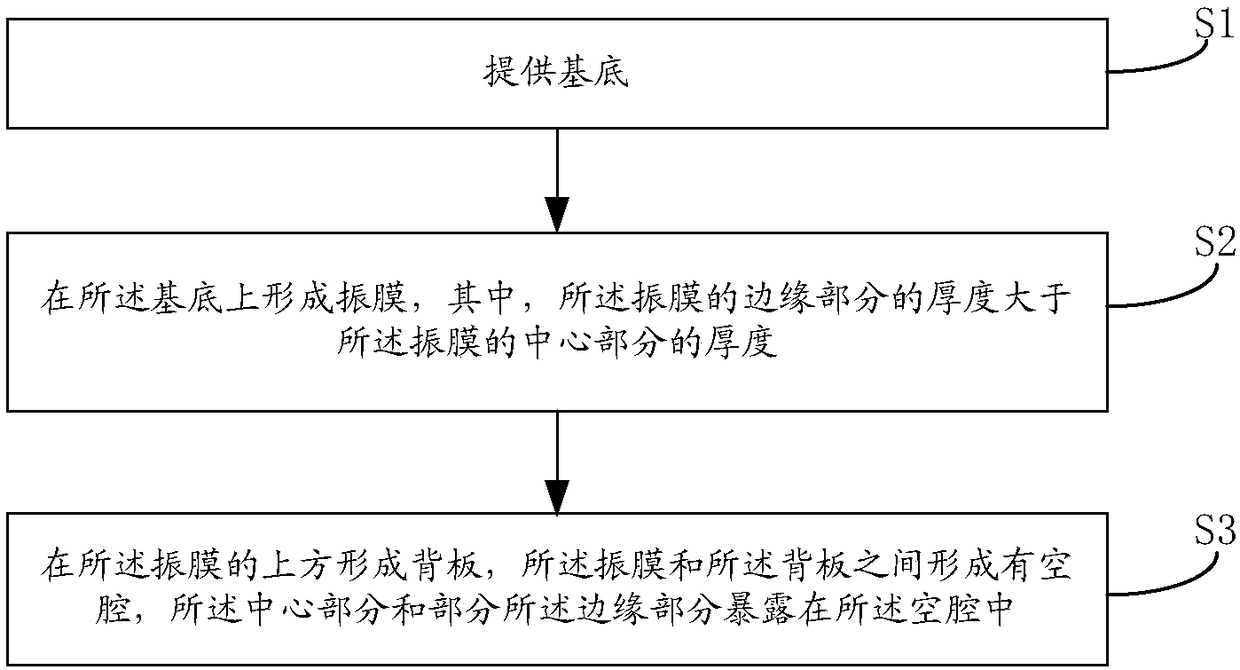

[0111] figure 1 The process flow chart for the preparation of the MEMS device described in the present invention specifically includes the following steps:

[0112] Step S1: providing a substrate;

[0113] Step S2: forming a diaphragm on the base, wherein the thickness of the edge portion of the diaphragm is greater than the thickness of the central portion of the diaphragm;

[0114] Step S3: forming a back plate above the diaphragm, a cavity is formed between the diaphragm and the back plate, and the central part and part of the edge parts are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com