Basalt fiber melting tank furnace

A basalt fiber and melting pool technology, applied in furnaces, retort furnaces, furnace types, etc., can solve the problems of narrow temperature range, low fiber yield, high wire drawing viscosity temperature, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

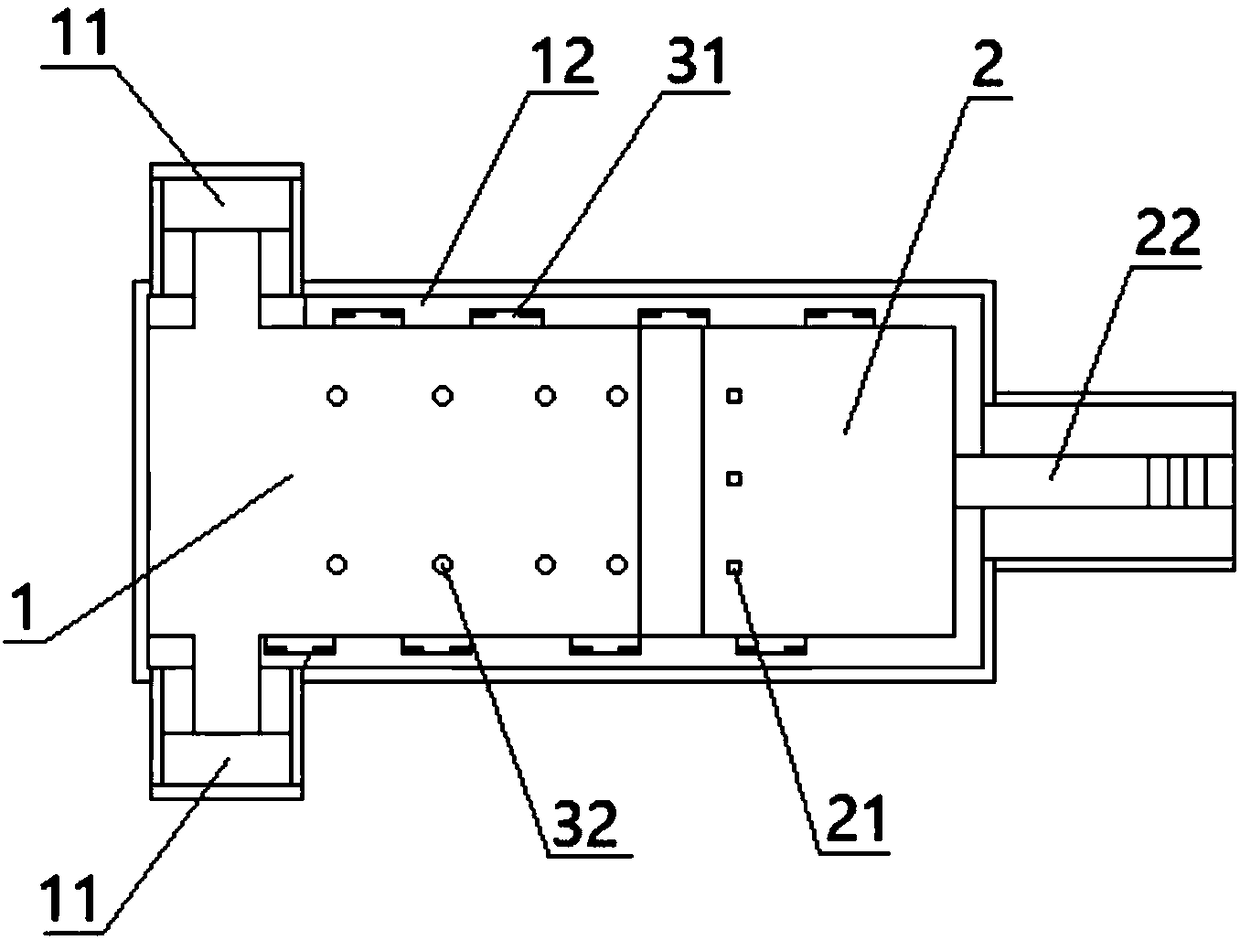

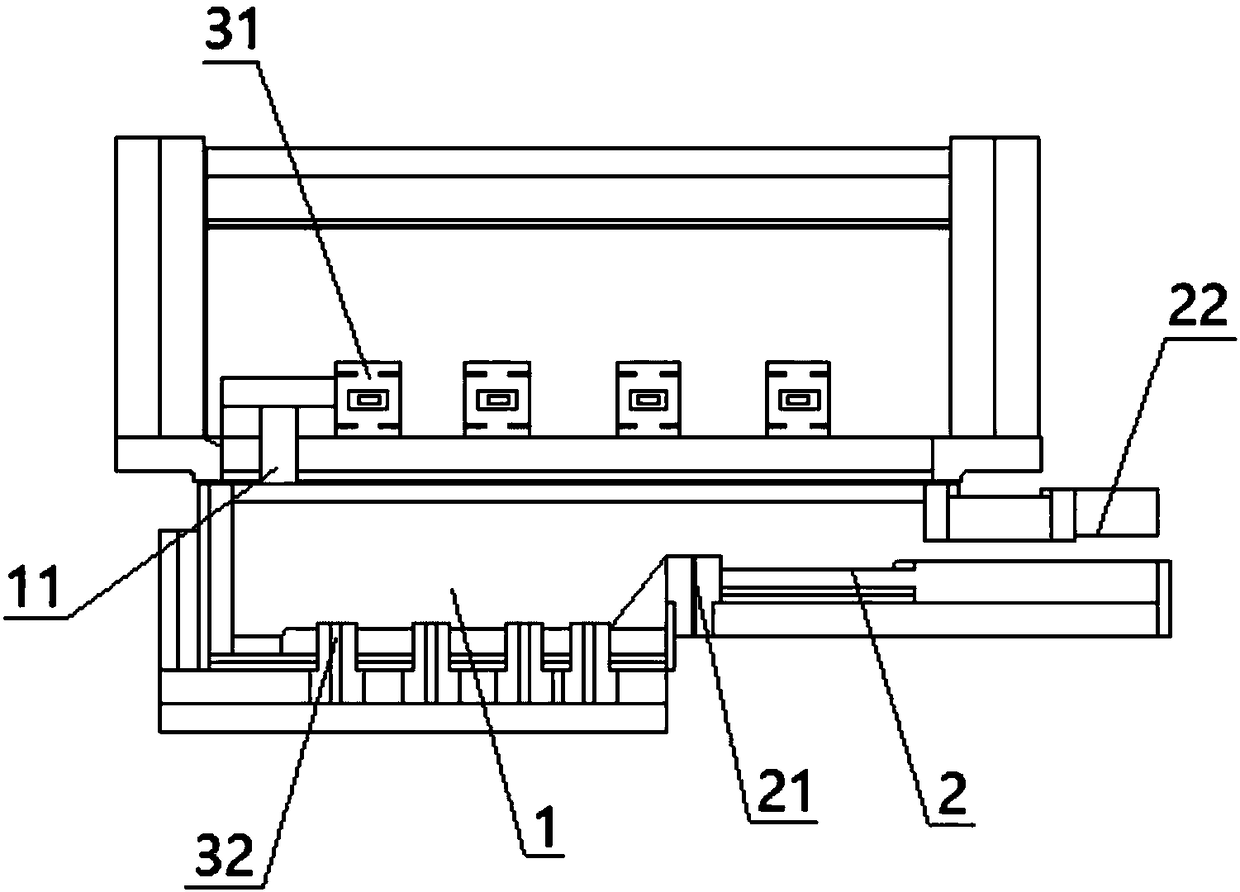

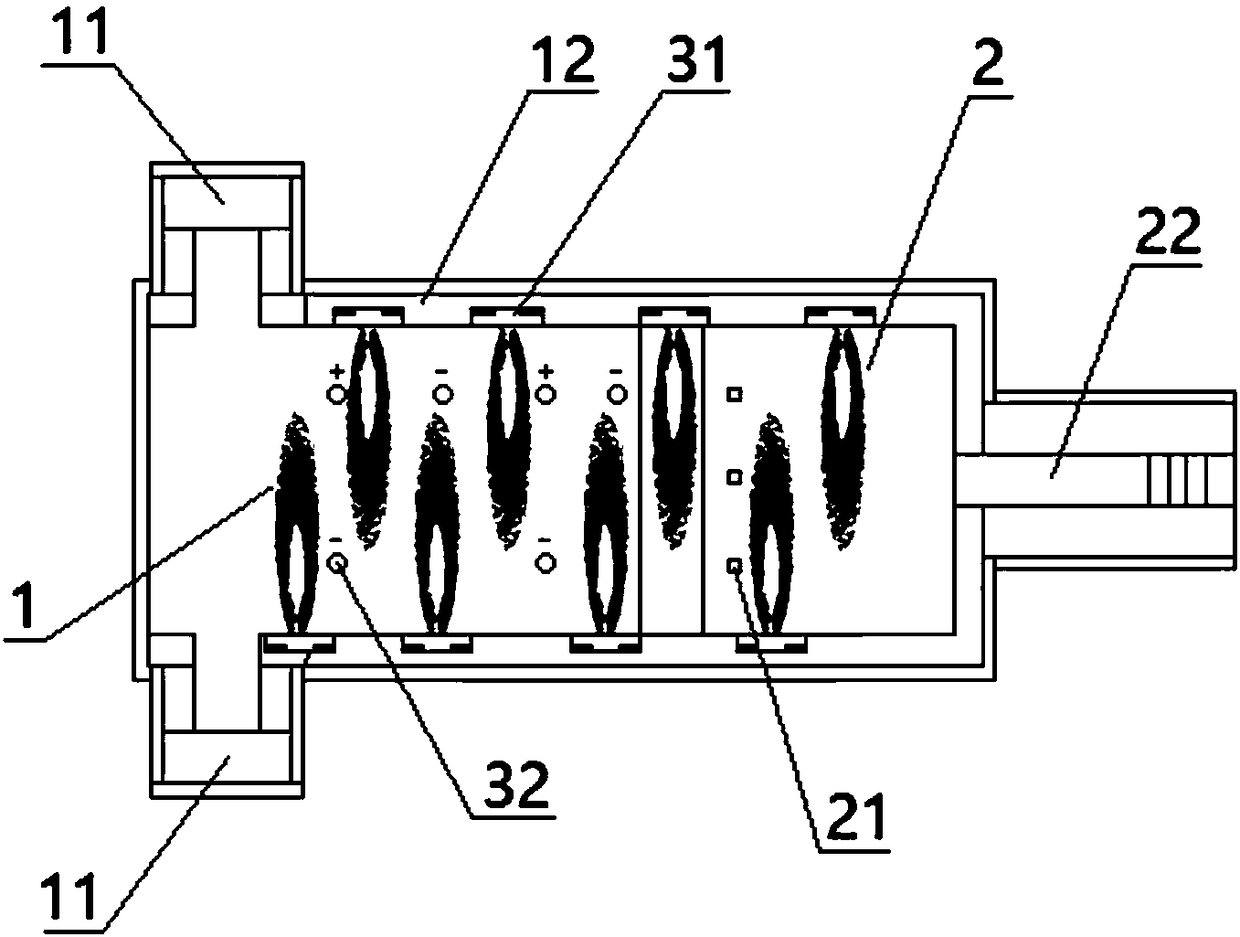

[0027] Embodiments of the present invention provide a basalt fiber melting pool kiln, comprising a cuboid kiln with an aspect ratio of 3:1, said kiln comprising a melting zone 1 and a clarification zone 2 connected to each other; the depth of the melting zone 1 is 200-600mm, 500mm is used as the preferred value in this embodiment, the depth of clarification zone 2 is 50-200mm shallower than that of the melting zone, 400mm is used as the preferred value in this embodiment, and the transition between clarification zone 1 and melting zone 2 is connected by an inclined plane . The side of the melting zone 1 away from the clarification zone 2 is provided with a feed port 11; the side wall of the melting zone 1 is provided with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com