N-doped TiO2/MXene composite material and preparation method and application thereof

A composite material and mixed liquid technology, applied in the field of nanomaterials, can solve problems such as specific capacity to be improved, unfavorable electrons or ions, rapid migration, etc., and achieve stable charge and discharge cycle characteristics, high specific capacity, and the effect of expanding the distance between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

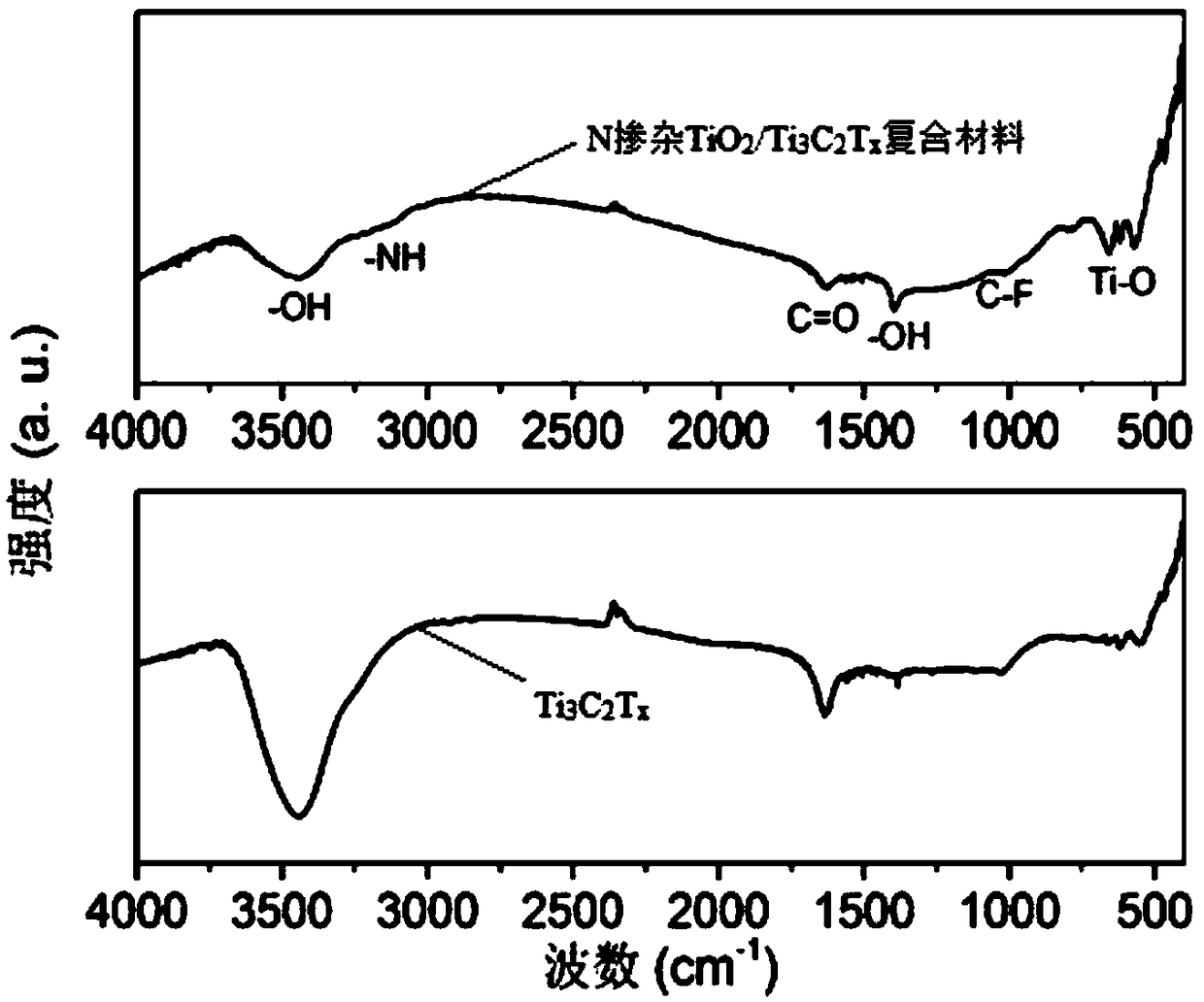

[0038]see figure 1 Preparation of N-doped TiO in 2 Process for preparing N-doped TiO / MXene composites 2 / MXene composite material and use it as raw material to prepare supercapacitor electrode, the specific method is as follows:

[0039] (1) Put Ti 3 AlC 2 The material was added to a hydrofluoric acid solution with a concentration of 30wt% at a concentration of 0.1g / mL, stirred at 60°C for 4h, centrifuged at a speed of 8000rpm for 20min, and then the lower solid was washed with deionized water to medium The two-dimensional layered nanomaterial MXene-Ti with a thickness of 0.01-3 μm was prepared after vacuum drying at 60 °C for 10 h. 3 C 2 T x .

[0040] (2) the two-dimensional layered nanomaterial Ti prepared in step (1) 3 C 2 T x Add hexamethylenetetramine to deionized water at a mass ratio of 1:5, stir at a speed of 450rpm for 30min to obtain a mixed solution;

[0041] (3) Move the mixed solution obtained in step (2) to a Teflon reactor and seal it, react at 200°C...

Embodiment 2

[0044] see figure 1 Preparation of N-doped TiO in 2 Process for preparing N-doped TiO / MXene composites 2 / MXene composite material and use it as raw material to prepare supercapacitor electrode, the specific method is as follows:

[0045] (1) Put Ti 3 AlC 2 The material was added to a hydrofluoric acid solution with a concentration of 10wt% at a concentration of 0.01g / mL, stirred at 20°C for 60h, centrifuged at a speed of 8000rpm for 20min, and then the lower solid was washed with deionized water to medium The two-dimensional layered nanomaterial MXene-Ti with a thickness of 0.01-5 μm was prepared after vacuum drying at 100 °C for 3 h. 3 C 2 T x .

[0046] (2) the two-dimensional layered nanomaterial Ti prepared in step (1) 3 C 2 T x Add hexamethylenetetramine to deionized water at a mass ratio of 1:15, and stir at a speed of 450rpm for 30min to obtain a mixed solution;

[0047] (3) Move the mixed solution obtained in step (2) to a Teflon reactor to seal, react at 9...

Embodiment 3

[0050] see figure 1 Preparation of N-doped TiO in 2 Process for preparing N-doped TiO / MXene composites 2 / MXene composite material and use it as raw material to prepare supercapacitor electrode, the specific method is as follows:

[0051] (1) Put Ti 3 AlC 2 The material was added into a hydrofluoric acid solution with a concentration of 40wt% at a proportioning concentration of 0.2g / mL, stirred at 40°C for 36h, centrifuged at a speed of 8000rpm for 20min, and the lower solid was washed with deionized water to medium The two-dimensional layered nanomaterial MXene-Ti with a thickness of 0.01-2 μm was prepared after vacuum drying at 80 °C for 6 h. 3 C 2 T x .

[0052] (2) the two-dimensional layered nanomaterial Ti prepared in step (1) 3 C 2 T x Add hexamethylenetetramine to deionized water at a mass ratio of 1:9, stir at a speed of 450rpm for 30min to obtain a mixed solution;

[0053] (3) Move the mixed solution obtained in step (2) to a Teflon reactor to seal, react ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com