Fig and abelmoschus manihot puffed food and preparation method thereof

A technology of puffed food and hollyhocks, which is applied in the directions of food ingredients, food forming, and function of food ingredients, etc., can solve problems such as difficulty in storage and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

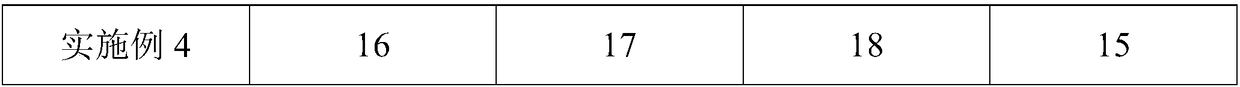

Examples

Embodiment 1

[0019] A fig and hollyhock puffed food, its raw materials include by weight: 15 parts of figs, 10 parts of hollyhock, 18 parts of millet flour, 40 parts of yam powder, 8 parts of lotus seed powder, 7 parts of auxiliary materials, the auxiliary materials include white sugar, edible oil , table salt; wherein, the weight ratio of the white granulated sugar, edible oil, and table salt is 8:1:3.

[0020] The preparation method of described fig hollyhock puffed food, comprises the steps:

[0021] S1. Clean the fresh figs, add 2 times the amount of water, heat at 88°C for 40min, stop heating and let stand for 16h, squeeze the juice, filter, heat and concentrate at 100°C until the solid content reaches 25wt%, and then Carry out spray drying, cooling, obtain fig powder;

[0022] S2. Wash the hollyhock, then place it at 70° C. and dry until the water content is 6 wt%, take it out, cool it naturally, pulverize it, and pass through a 80-mesh sieve to obtain hollyhock powder;

[0023] S3...

Embodiment 2

[0026] A fig and hollyhock puffed food, its raw materials include by weight: 8 parts of figs, 20 parts of hollyhock, 12 parts of millet flour, 60 parts of yam powder, 5 parts of lotus seed powder, 10 parts of auxiliary materials, the auxiliary materials include white sugar, edible oil , table salt; wherein, the weight ratio of the white granulated sugar, edible oil, and table salt is 6:1:4.

[0027] The preparation method of described fig hollyhock puffed food, comprises the steps:

[0028] S1. Clean the fresh figs, add 1 times the amount of water, heat at 95°C for 25min, stop heating and let stand for 20h, squeeze the juice, filter, heat and concentrate at 95°C until the solid content reaches 30wt%, and then Carry out spray drying, cooling, obtain fig powder;

[0029] S2. Wash the hollyhock, then dry it at 60°C until the water content is 10wt%, take it out, cool it naturally, pulverize it, and pass through a 50-mesh sieve to obtain hollyhock powder;

[0030] S3. Mix fig pow...

Embodiment 3

[0033] A fig and hollyhock puffed food, the raw materials of which include by weight: 13 parts of figs, 12 parts of hollyhock, 17 parts of millet flour, 46 parts of yam powder, 7 parts of lotus seed powder, and 8 parts of auxiliary materials. The auxiliary materials include white sugar and edible oil. , table salt; wherein, the weight ratio of the white granulated sugar, edible oil, and table salt is 8:1:3.

[0034] The preparation method of described fig hollyhock puffed food, comprises the steps:

[0035] S1. Clean the fresh figs, add 2 times the amount of water, heat at 90°C for 35min, stop heating and let stand for 17h, squeeze the juice, filter, heat and concentrate at 98°C until the solid content reaches 26wt%, and then Carry out spray drying, cooling, obtain fig powder;

[0036] S2. Wash the hollyhock, then dry it at 68°C until the water content is 7wt%, take it out, cool it naturally, crush it, and pass it through a 70-mesh sieve to obtain hollyhock powder;

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com