Flue gas desulfurizer and flue gas dust collection, desulfurization and wastewater treatment method

A desulfurization tower, flue gas technology, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the constraints on the construction and upgrading of dust removal and desulfurization devices, the inability to upgrade the space of devices and boilers, and shutdowns or demolishing and rebuilding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

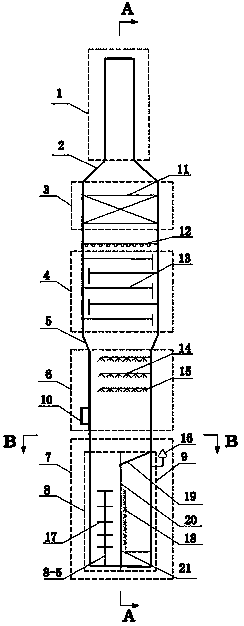

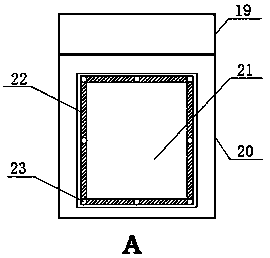

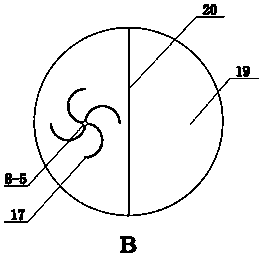

[0082] A flue gas dedusting and desulfurization tower, from top to bottom are the flue gas discharge area 1, the mist removal area 3, the tower area 4, the spray area 6 and the waste water treatment area 7, the flue gas discharge area 1 and the mist removal area 3 It is connected by a cone-shaped diameter 2, and below the demisting area 3 is a tray area 4, and the tray area 4 and the spray area 6 are connected by an inverted cone-shaped diameter 5, and below the spray area 6 is a waste water treatment area 7.

[0083] A wet electrostatic demister 11 is arranged in the demisting area 3, a liquid distributor 12 is arranged under the wet electrostatic demister 11, a tray area 4 is arranged under the liquid distributor 12, and a total of 4 layers of trays are arranged in the tray area 4. A sieve tray is selected; the spray area 6 is provided with three layers of spray pipelines 14, the distance between the spray pipelines 14 is 2m, and the atomizing nozzles 15 are evenly arranged o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com